Maintenance

06-237619-001 6-13 April 2020

6-10 INSPECTION PROCEDURES- 10 YEAR (EU)

In addition to performing the 2 year inspection, for EU approved cylinders perform the

following procedures every 10 years:

6-10.1 Retest Procedures for TPED Specification EU Cylinders

Where the visual inspection shows evidence of damage or corrosion, the cylinder shall be

emptied, re-tested and re-stamped in accordance with BS EN ISO 1968 latest edition.

Kidde IGS cylinders are manufactured to TPED/ADR/84/ 527/EEC.

6-10.1.1 Cylinders Continuously in Service without Discharge

These cylinders are governed by the Transportable Pressure Equipment Directive

(2010/35/EU). Cylinders in continuous service without discharge require a periodic inspection

in accordance with BS EN ISO 1968 latest edition. Record date of inspection on record tag

attached to each cylinder. Where the visual inspection shows evidence of damage or corrosion,

the cylinder shall be emptied, re-tested and re-stamped in accordance with BS EN ISO 1968

latest edition.

6-10.1.2 Discharge Cylinders or Charged Cylinders that are Transported

These cylinders are governed by the United Nations (UN) ADR and the European Union's (EU)

Transportation of Pressure Equipment Directive (2010/35/EU). In the case of shipment of

charged cylinders, other shipping regulations may also apply. In either case, cylinders in

continuous service without discharge require a periodic inspection in accordance with BS EN

ISO 1968 latest edition. Record date of inspection on record tag attached to each cylinder.

Where the visual inspection shows evidence of damage or corrosion, the cylinder shall be

emptied, re-tested and re-stamped in accordance with BS EN ISO 1968 latest edition.

6-10.1.3 Retest

Cylinders used with in Kidde IGS are required to be hydrostatically re-tested and re-stamped

in accordance with BS EN ISO 1968 latest edition prior to recharge and shipment. It is company

policy that at the time of hydrostatic testing that valves are replaced with new.

WARNING

Cylinder assemblies must be returned with all valve and discharge protection

caps in place. These shall be attached immediately after disconnection from

pipework. Failure to do so may result in damage to equipment and cause severe

bodily injury.

CAUTION

These guidelines only apply to cylinders containing the agent.

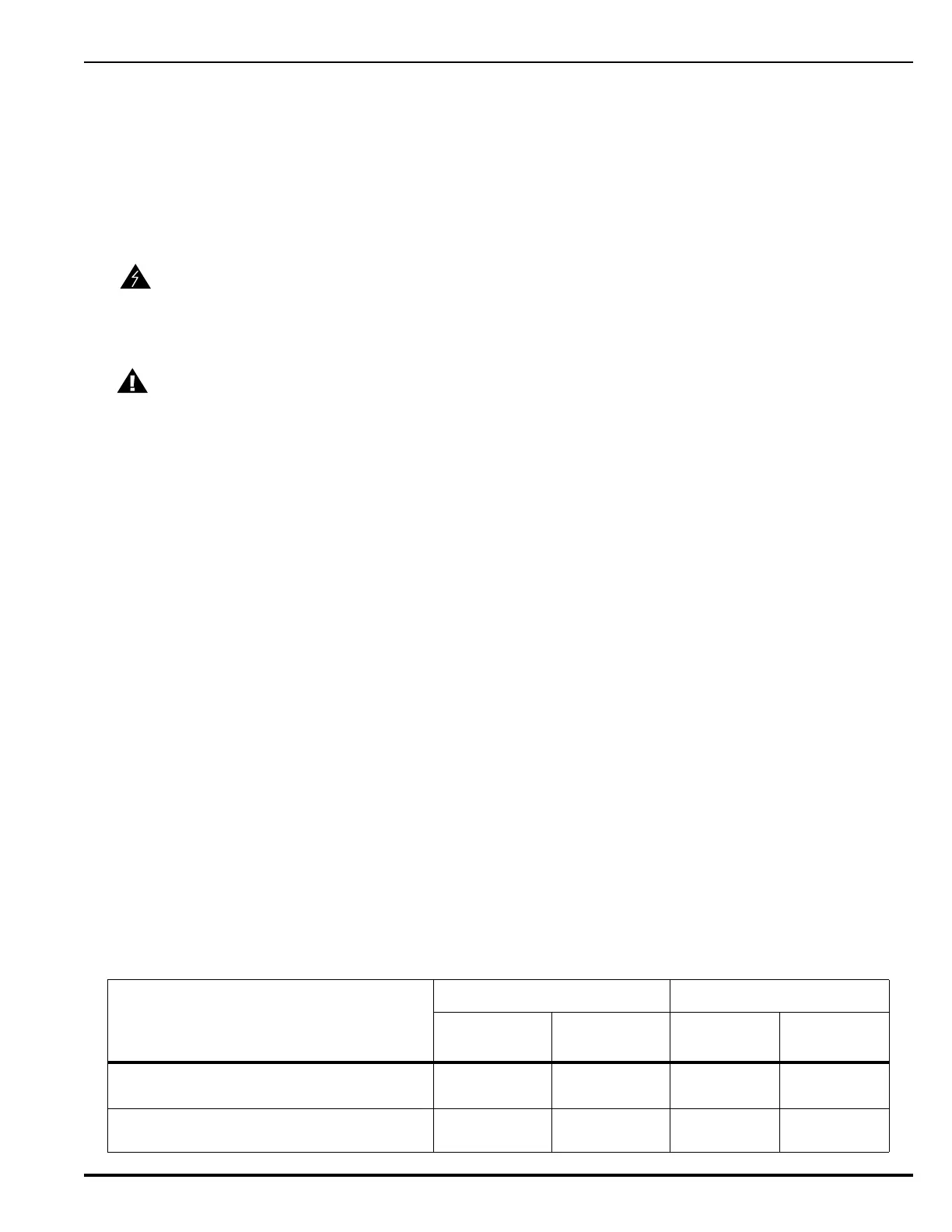

Table 6-3. Retest Schedule EU Specification Cylinders

Inspection Method

TPED/ADR/84/527/EEC TPED/TRG330/ADR

First

Retest Due

Subsequent

Retest Due

First

Retest Due

Subsequent

Retest Due

Fully hydrostatic test including

determination of cylinder expansion

10 years 10 years 10 years 10 years

External visual inspection per BS EN ISO

14520 requirement

6 months 6 months 6 months 6 months

Loading...

Loading...