8

INFORMATION ABOUT OVERHAULING

EN 100

NOTE: During the positioning phase of reference X,

check that cylinder N° 1 is in compression phase

(intake and exhaust valves of cylinder N° 1 must be in

closing position).

Tab. 8.4 T

appets and t

appet housing size.

DIMENSIONS (mm)

CLEARANCE VALUE (mm)

0.060 - 0.105

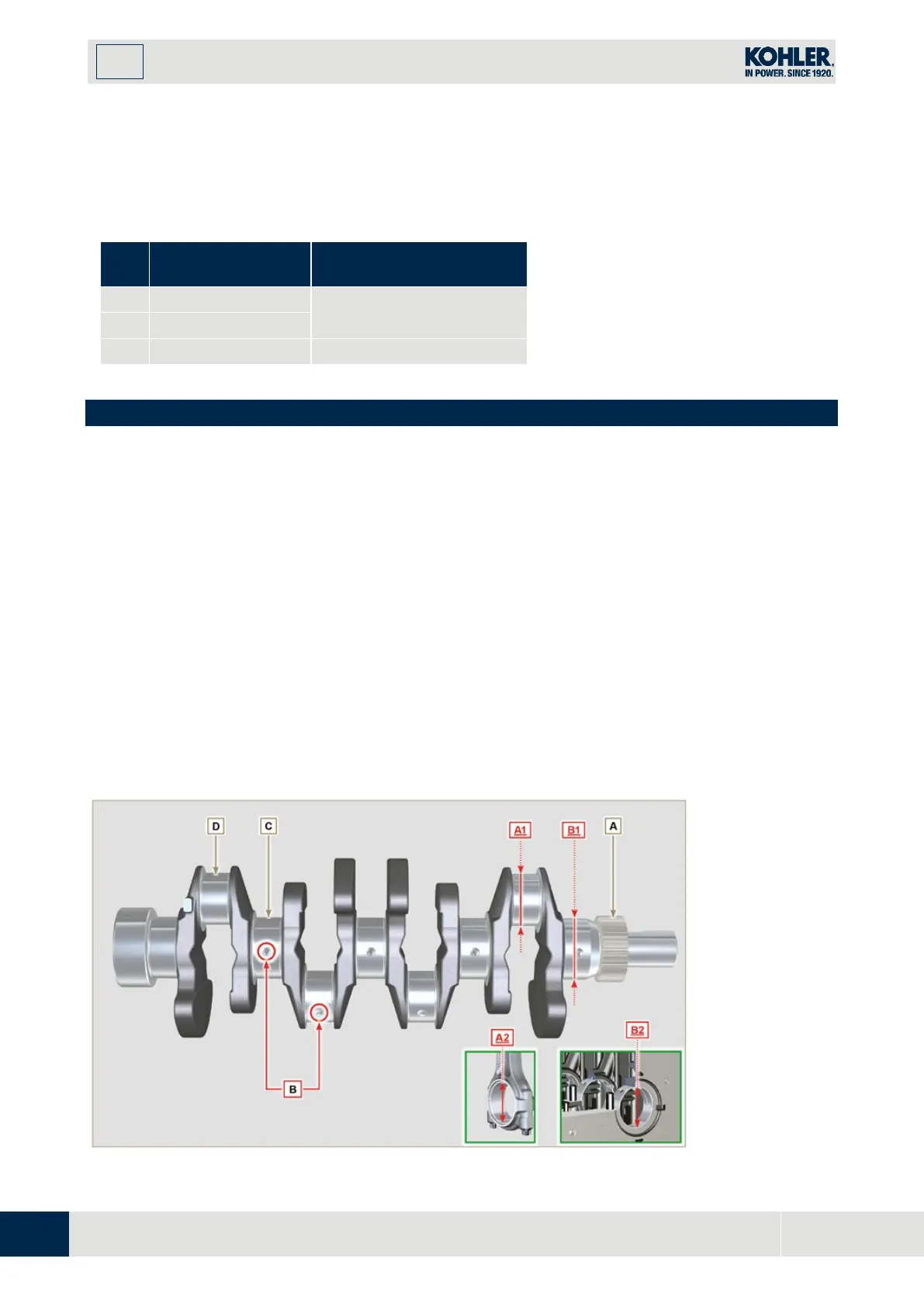

8.4 Crankshaft

8.4.1 Dimensional check and overhauling

Wash the crankshaft thoroughly using suitable detergent.

Insert the pipe cleaner into all lubrication ducts B and blow compressed air to free them completely from

any dirt residues.

Check the state of wear and integrity of journals C and connecting rod D.

P

erform the operations described in Par. 9.3.1, perform the operations described in Par. 9.3.6 - except

Points 2, 4, 9 and 10.

Measure the crank pins A1 with a micrometer, and using a dial gauge measure the internal diameter of the

connecting rod half-bearings A2.

Measure the main journals B1, with a micrometer, and using a dial gauge measure the internal diameter of

the crankshaft half-bearings B2.

If the values described in Tab. 8.5 do not correspond, proceed with grinding all gudgeon pins A1 and B1.

G

ear A on the crankshaft is timed by a key, assembly of gear A on the shaft occurs after heating at a

stabilized temperature of +180° C for 5 mins.

F

ig 8.9

Loading...

Loading...