ASSEMBLY INFORMATION

9

117

EN

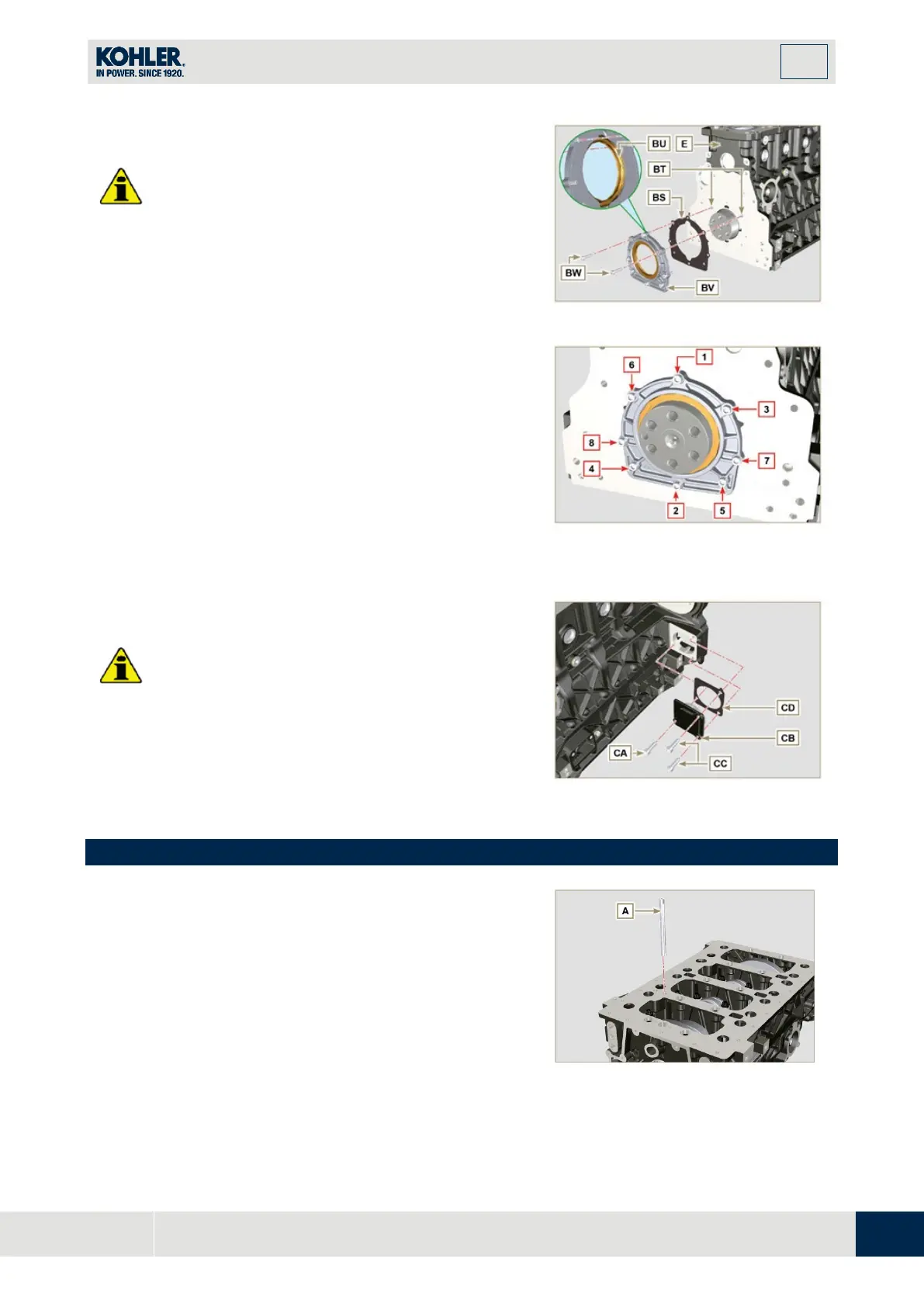

9.3.10 Crankshaft gasket flange

Important

•

Check that the contact surface between the flang

e

an

d the crankcase is free of grit and dirt.

•

Always replace the gasket BS after each assembly.

1.

Check that there are bushings BT on the crankcas

e

E.

2.

L

ubricate the oil seal lip BU.

3.

Position the gasket BS and flange BV on the

crankcase E in correspondence with the bushings

BT.

4.

Put Loctite 243 on the 2 screws BW matching the

bushings BT.

5.

Screw the fastening screws all the way in BW without

tightening them.

6.

Tighten all the screws BW strictly following the

tightening sequence indicated (tightening torque to

10 Nm).

Fig 9.19

F

ig 9.20

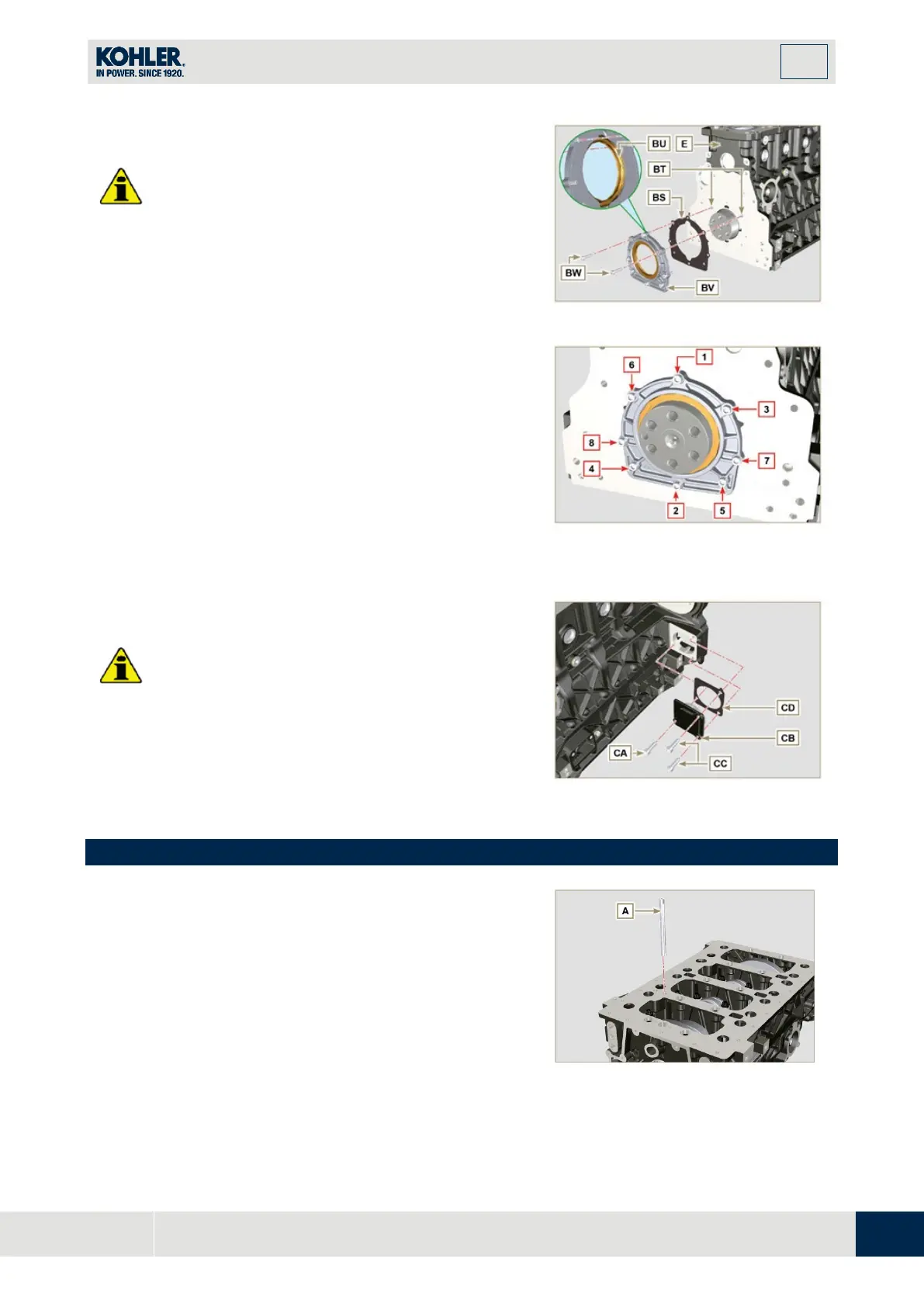

9.3.11 Cover 3

PTO

Important

•

Replace capscrews CA with each assembly or

alternatively apply Loctite 2701 on the thread.

1.

Secure the cover CB with the screws CA and CC

inserting the gasket CD (tightening torque 25 Nm).

Fig 9.21

9.4 Oil sump unit assembly

9.4.1 Oil fume pipes

1.

Apply Loctite 648 on the pipe threads A.

2.

Screw and tighten the pipes A (tightening torque of

15 Nm).

Loading...

Loading...