12

INFORMATION ON ADJUSTMENTS

EN 178

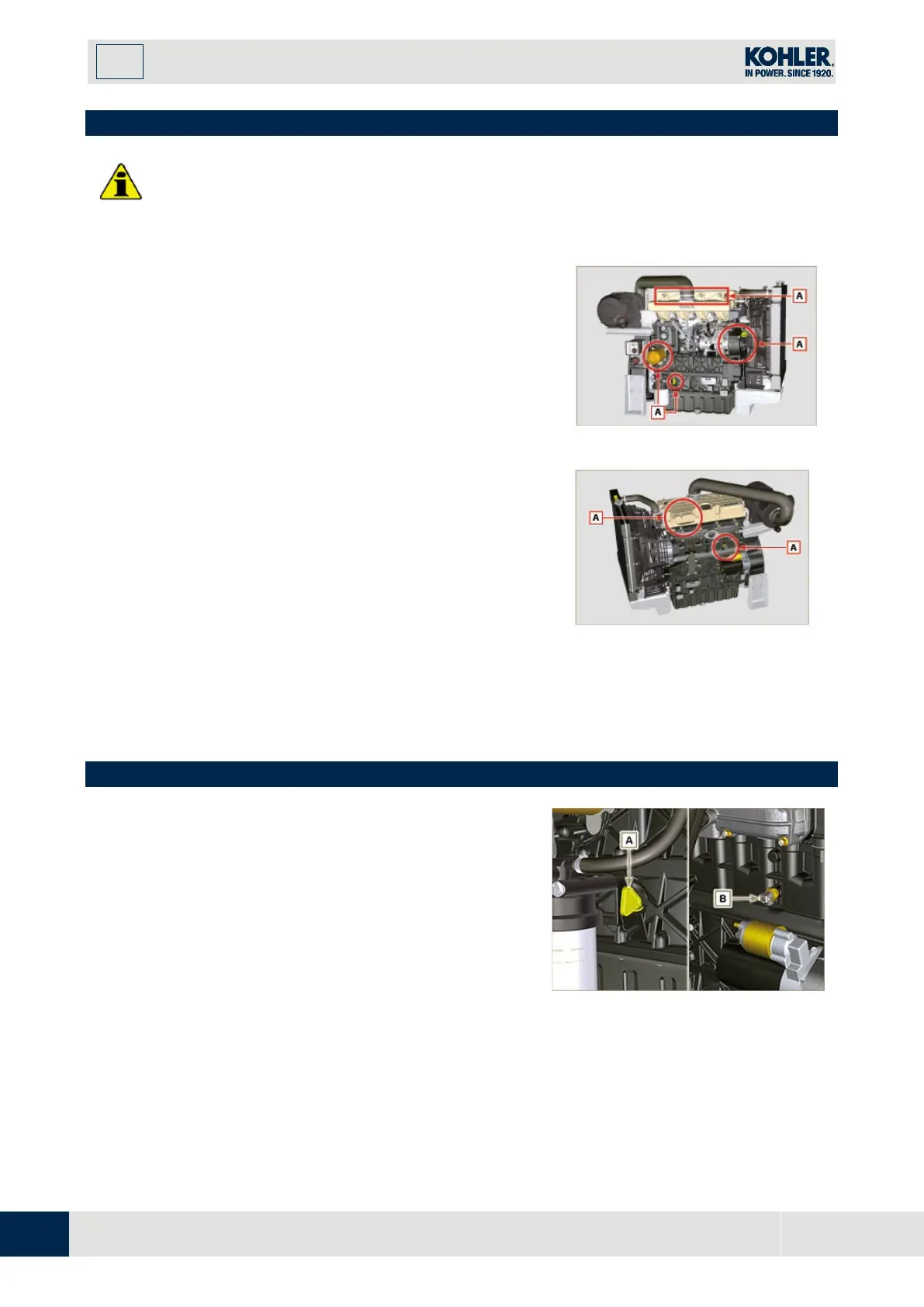

12.3 Oil leak check

•

Before proceeding with operation, read Par. 3.3.2.

Check that there are no leakages next to area

A

.

1.

Start the engine at idle speed or without a load and

check whether there are any leakages next to area A.

2.

It is anyhow necessary to also check the seals of all

main components and their surface contact, such as:

- crankcase and oil seal (side 1

a

PTO)

- oil sump and exhaust caps

- cylinder head and its assembled components

- roc

ker arm cover

- T

iming system carter and oil seal (side 2

a

PTO)

- oil dipstick housing or rod support tube.

NOTE:

Perform the checks described in

Points 1 and 2

periodically and during maintenance procedures.

It is also necessary to check for leakages on the components

that are not listed.

If necessary, disassemble the components that have a leakage

and investigate the possible cause.

The components must be replaced otherwise they do not

Fig 12.4

Fig 12.5

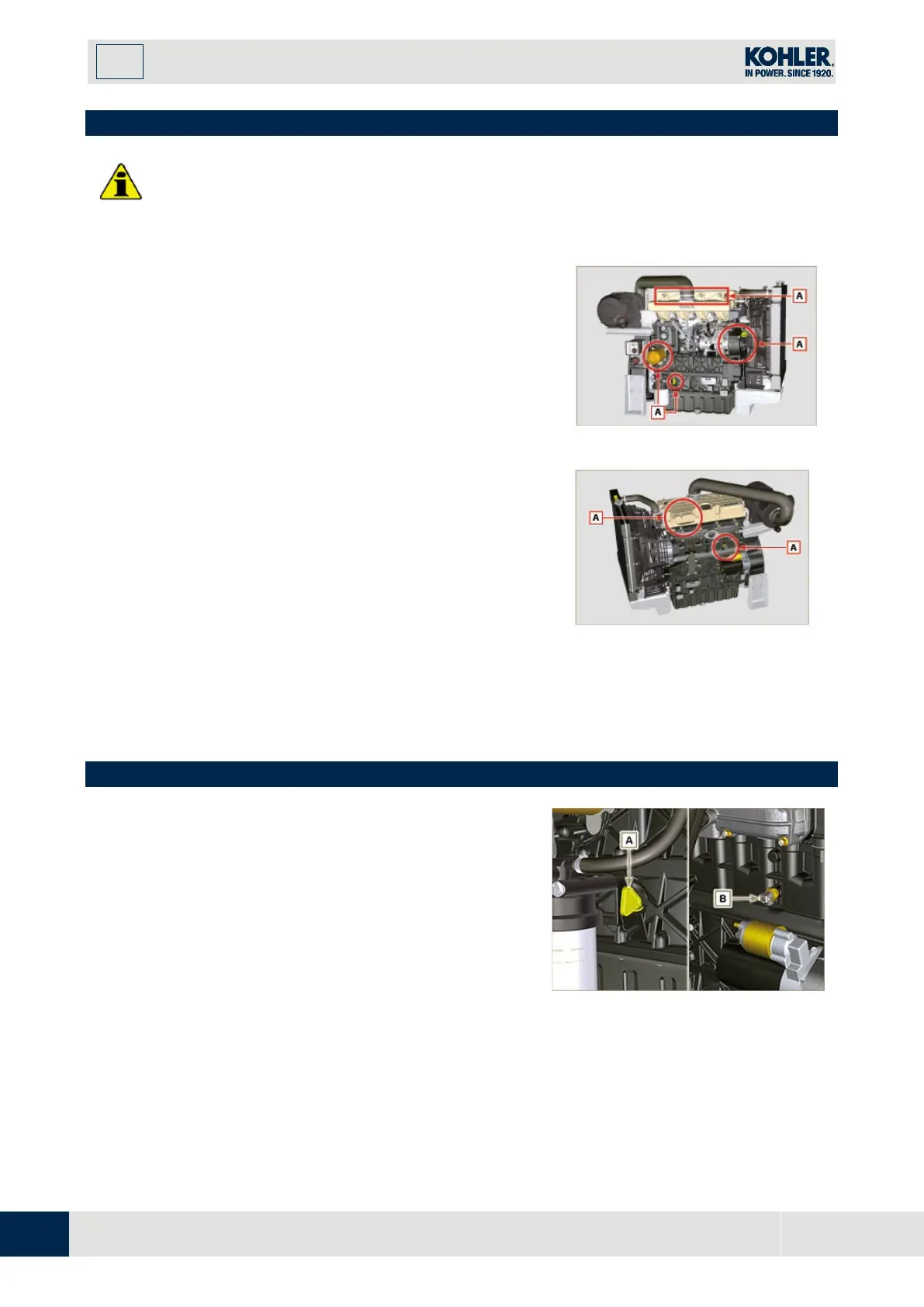

12.4 Oil pressure check

Insert a thermocouple instead of the oil dipstick A.

2.

Unscrew and remove the oil pressure switch B an

d

s

crew on a 10 bar pressure gauge in its seat (Fig.

12.8).

3.

Start the engine at idle speed and without a load,

check the oil pressure value according to the oil

temperature (Fig. 12.7).

NOTE

: The graph in

Fig. 12.7

illustrates the pressure line with

speed of 1000 Rpm.

4.

If the pressure values are below the values indicated

in Fig. 12.7, check to identify the cause of th

e

pr

oblem.

Fig. 12.6

Loading...

Loading...