9

ASSEMBLY INFORMATION

EN 122

7.

Fix pump Z into housing V by means of screws T

(Fig. 9.34 - tightening torque at 25 Nm).

8.

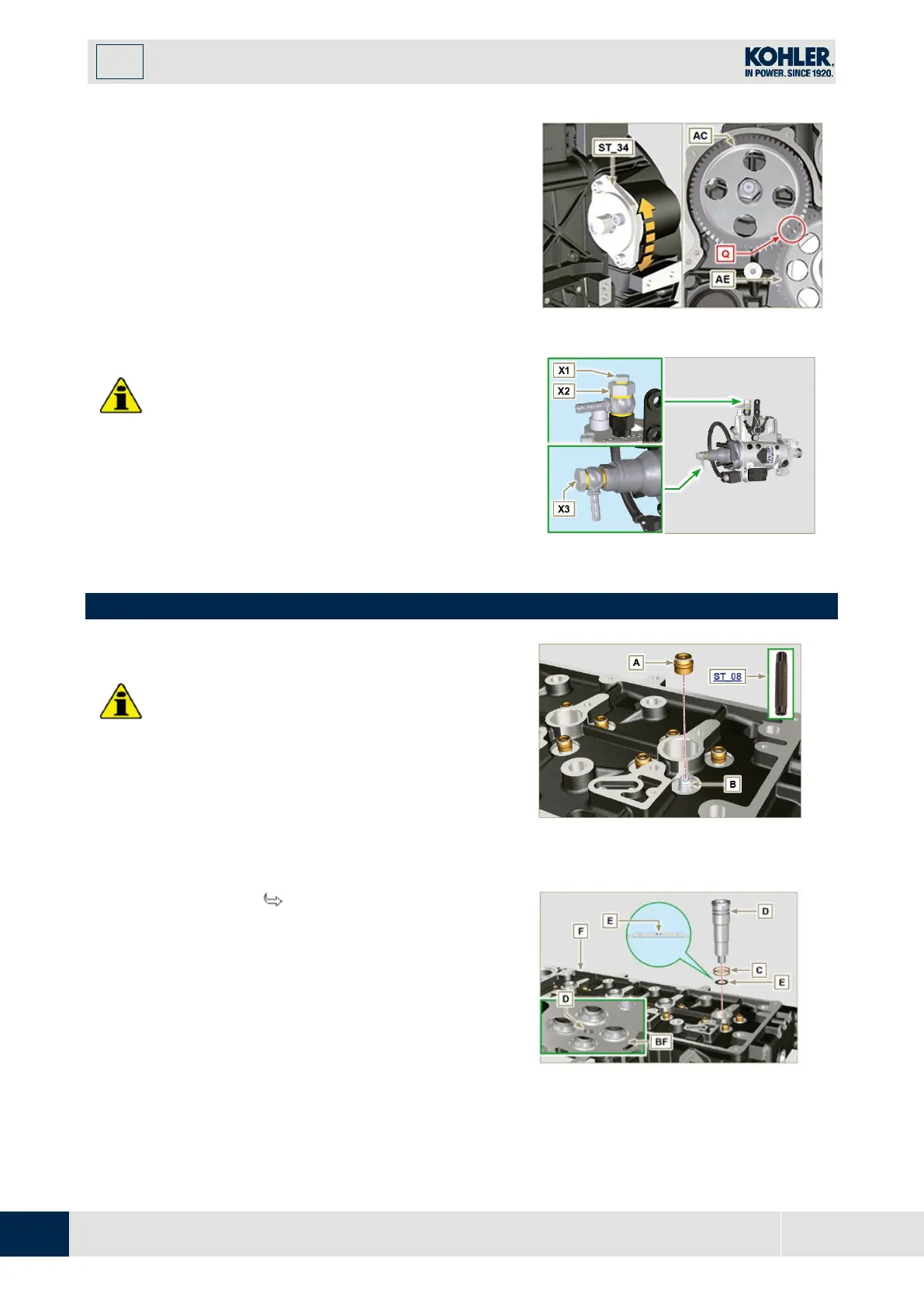

Position the gear AC onto shaft AB of the pump.

NOTE:

You are not required to respect the reference

Q

gear

AE

(

Fig.

9.36

).

9.

Insert washer U and tighten nut AD (tightening

torque at 70 Nm).

I

mportant

•

In the event of assembling screw X1 (tightening

torque at 10 Nm).

•

In the event of assembling screws X2 and X3

(tightening torque at 2 5 Nm).

Fig 9.36

Fig 9.37

9.7 Cylinder head unit assembly

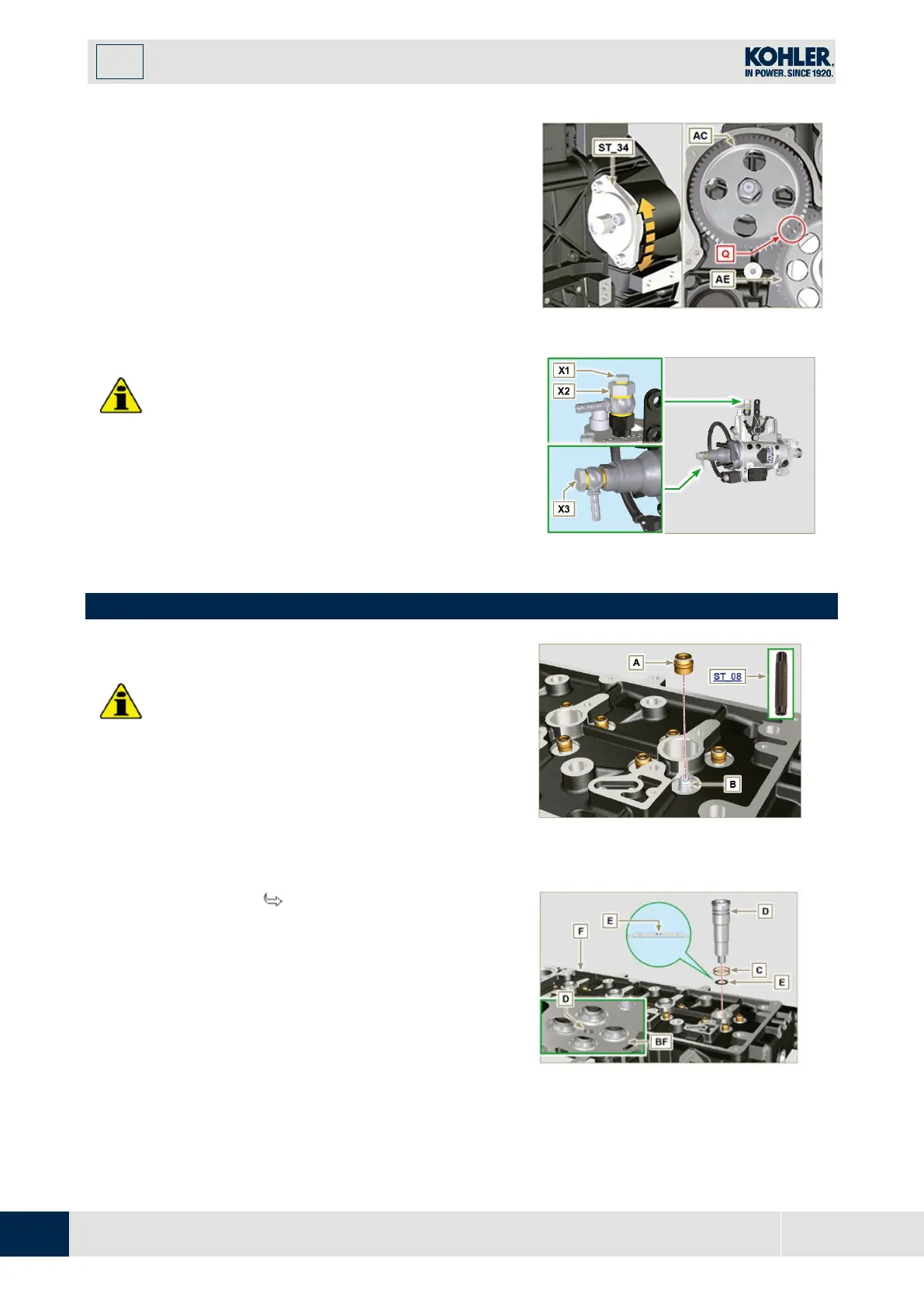

Important

•

Carry out the checks described in Par. 8.6.4 befor

e

p

roceeding with the following operations.

•

Always replace gasket A with every assembly

•

Lubricate the gaskets A on the inside.

1.

Fit the oil seals A on the valve guides B using the

tool ST_08.

Fig 9.38

9.7.2 Injector sleeves

( )

1.

Insert the seals C in the seats of the sleeve D.

2.

Insert the seal E with the convex side facing

upward at the base of the sleeve D.

3.

Lubricate the gaskets C.

4.

Insert and carefully screw the sleeve D into the

seat of the head F.

NOTE: The sleeve D must not protrude above the surface

of the head BF.

5.

Clamp the sleeve D (tightening torque at 30 Nm).

Fig 9.39

Loading...

Loading...