ASSEMBLY INFORMATION

9

121

EN

Important

•

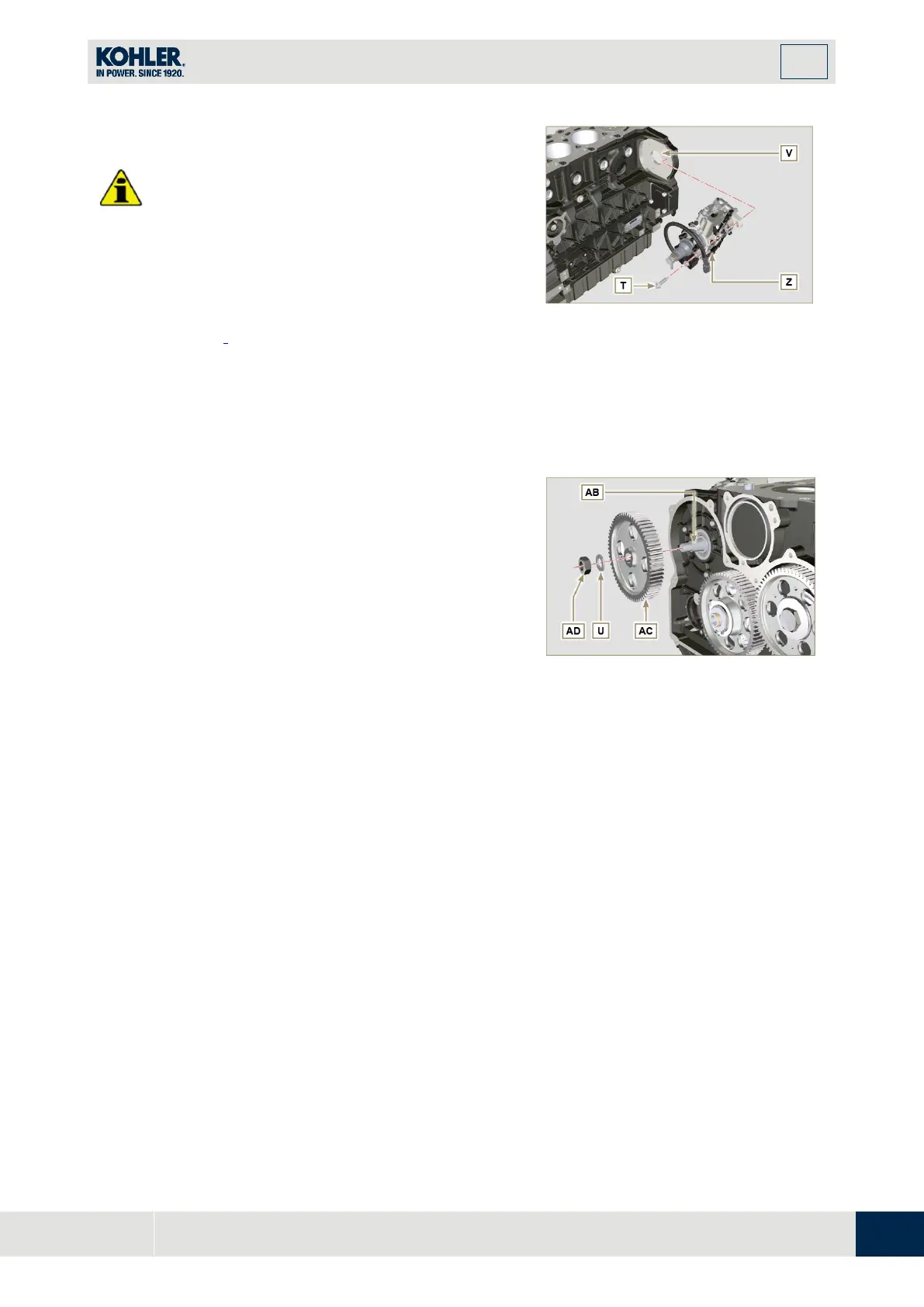

Always change screws T with new ones or

alternatively apply Loctite 270 (Fig. 9.34) to the

threads.

1.

Perform the operations described in the warning in

Par. 6.1.5.

2.

Place a dial gauge to detect the TDC on piston N° 1,

then bring the indicator of the dial gauge to 0.

NOTE

: During the detection phase of the TDC, check that

cylinder N°

1

is in compression phase (align the notches

W

as in

Fig. 9.33

).

Fig 9.34

By means of the identified pump code, refer to Tab.

6.1 to know the advance degrees and th

e

c

orresponding value to lower the piston.

4.

Mount tool ST_34 in the seat of starter motor

H

(

Fig. 9.29) and fix it with two motor fixing screws.

5.

Having identified the value to lower the piston,

rotate the crankshaft anti-clockwise by goin

g

b

eyond the value described in Tab. 6.1, once again,

rotate the crankshaft clockwise stopping at the

correct advance value by using tool ST_03 - ST_34.

6.

Lock the ST_34, ensure that the crankshaft does

not rotate, which would alter the correct advan

ce

v

alue.

If this happens, repeat the instructions described i

n

p

oints 4, 5 and 6.

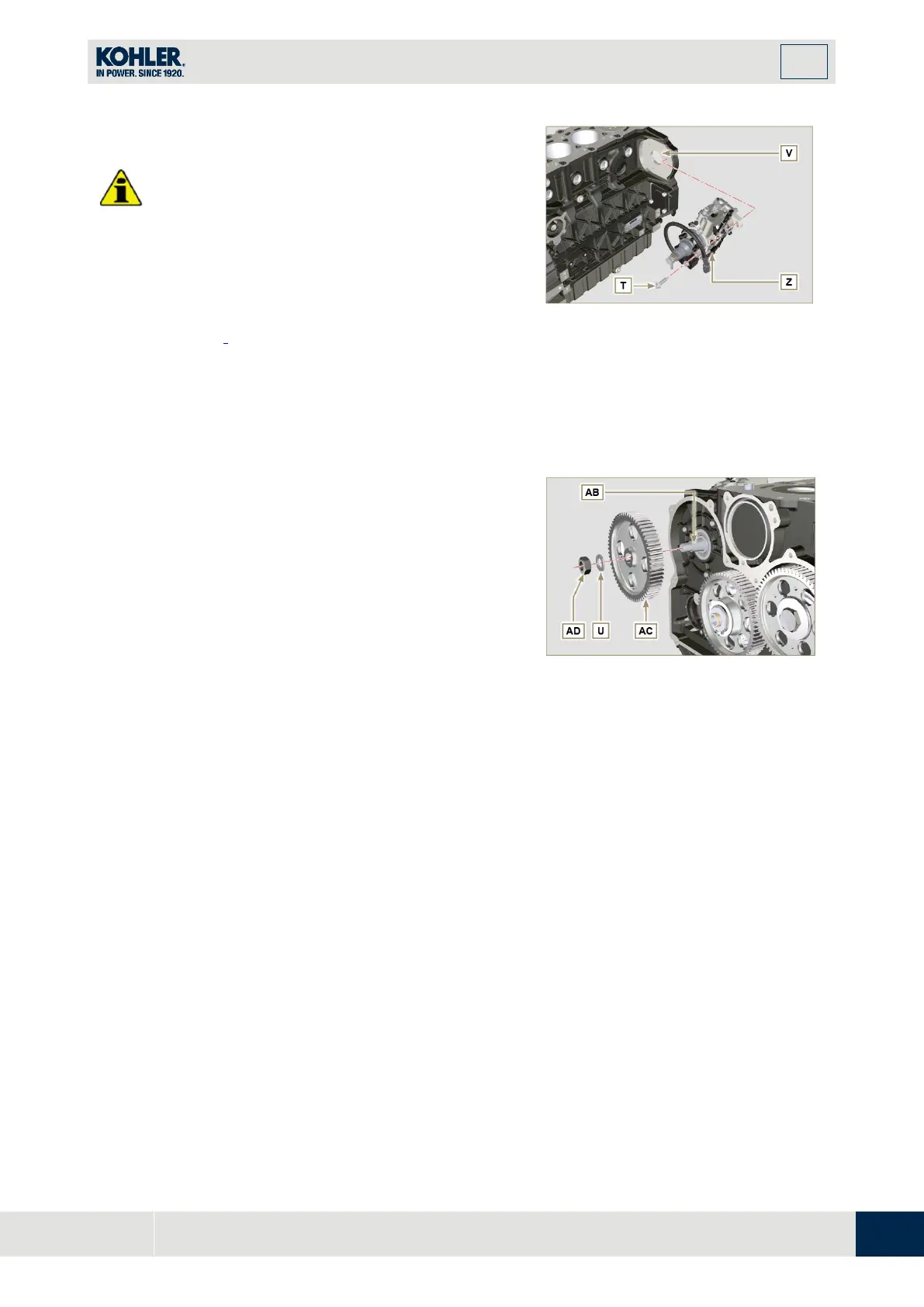

Fig 9.35

Loading...

Loading...