INFORMATION FOR REPLACING THE

FUNCTIONAL UNITS

6

73

EN

8.

Fit the timing system crankcase C with the

screws R observing the indicated clamping

sequence (tightening torque at 25 Nm).

6.4.7 Crankshaft pulley assembly

1.

Perform the operations described in Par 6.3.2.

6.4.8 Coolant pump assembly

1.

Perform the operations described in Par 6.2.2.

6.5 Oil pressure valve replacement

Important

•

Before proceeding with operation, read Par. 3.3.2.

1.

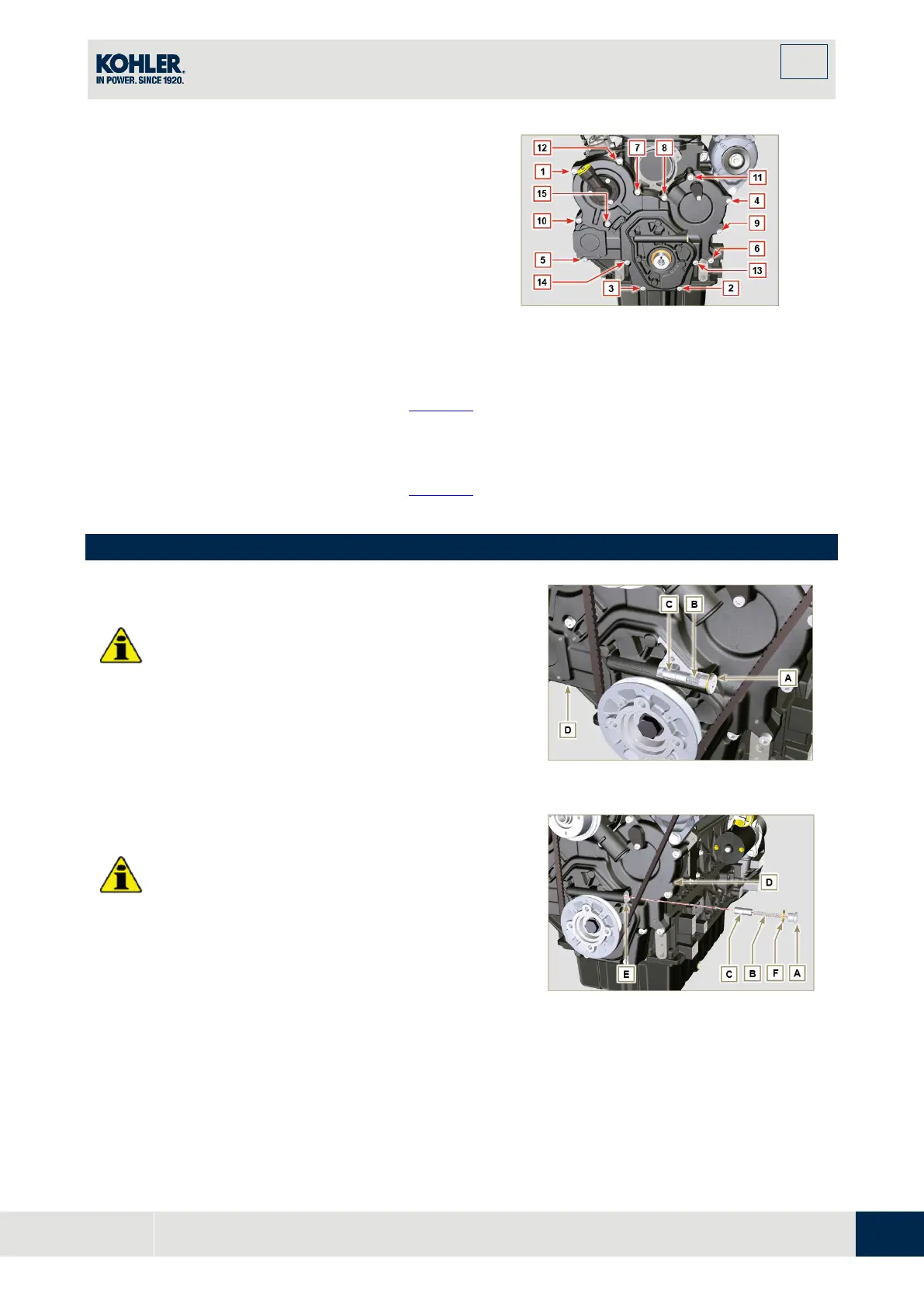

Undo the cap A.

2.

From the crankcase D, remove the spring B.

3.

Remove the valve piston C using a magnet.

Fig 6.46

Important

•

Carry out the checks described in Par. 8.7.3 prior t

o

a

ssembly.

•

Always replace the gasket F after each assembly.

1.

Lubricate the piston C and fully insert it in the seat

E.

2.

I

nsert the spring B in the piston.

3.

Mount the gasket F on cap A.

4.

Clamp the cap A on the crankcase D (tightening

torque at 50 Nm).

Fig 6.47

Loading...

Loading...