ASSEMBLY INFORMATION

9

131

EN

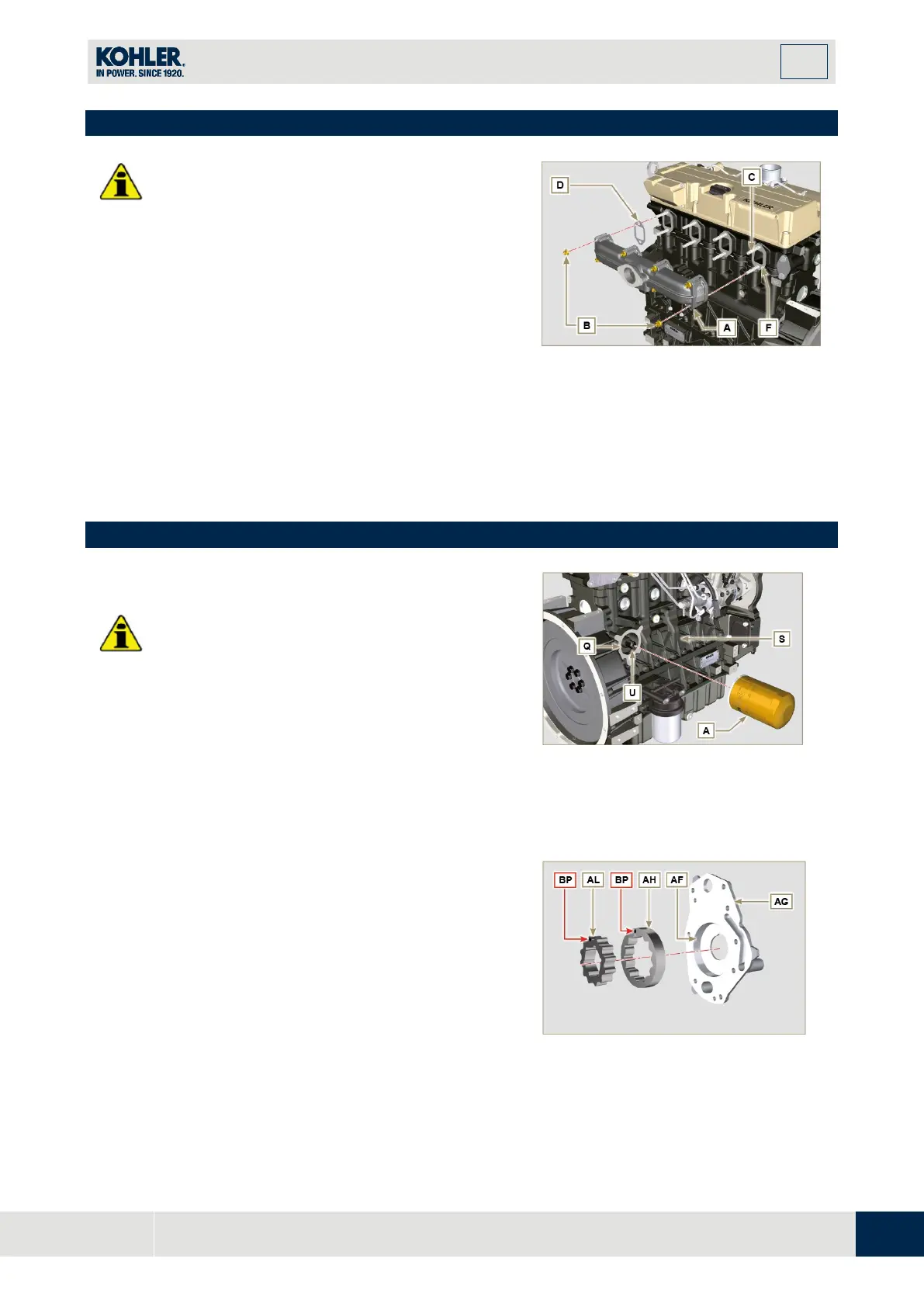

9.10 Exhaust manifold assembly

•

Replace the self-locking nuts B and the metal

gaskets D between the manifold and the cylinder

head every time they are assembly.

•

In the event of mounting the studs C, fix (25 Nm

tightening torque) with Loctite 2701 on the thread.

1.

Check that the contact surfaces F are free from

impurities.

2.

Insert the gaskets D and E on the studs C.

3.

Position the manifold A on the studs C.

4.

Fix the manifold A on the cylinder head by

tightening the self-locking nuts B (tightening torque

of 25 Nm).

Fig 9.71

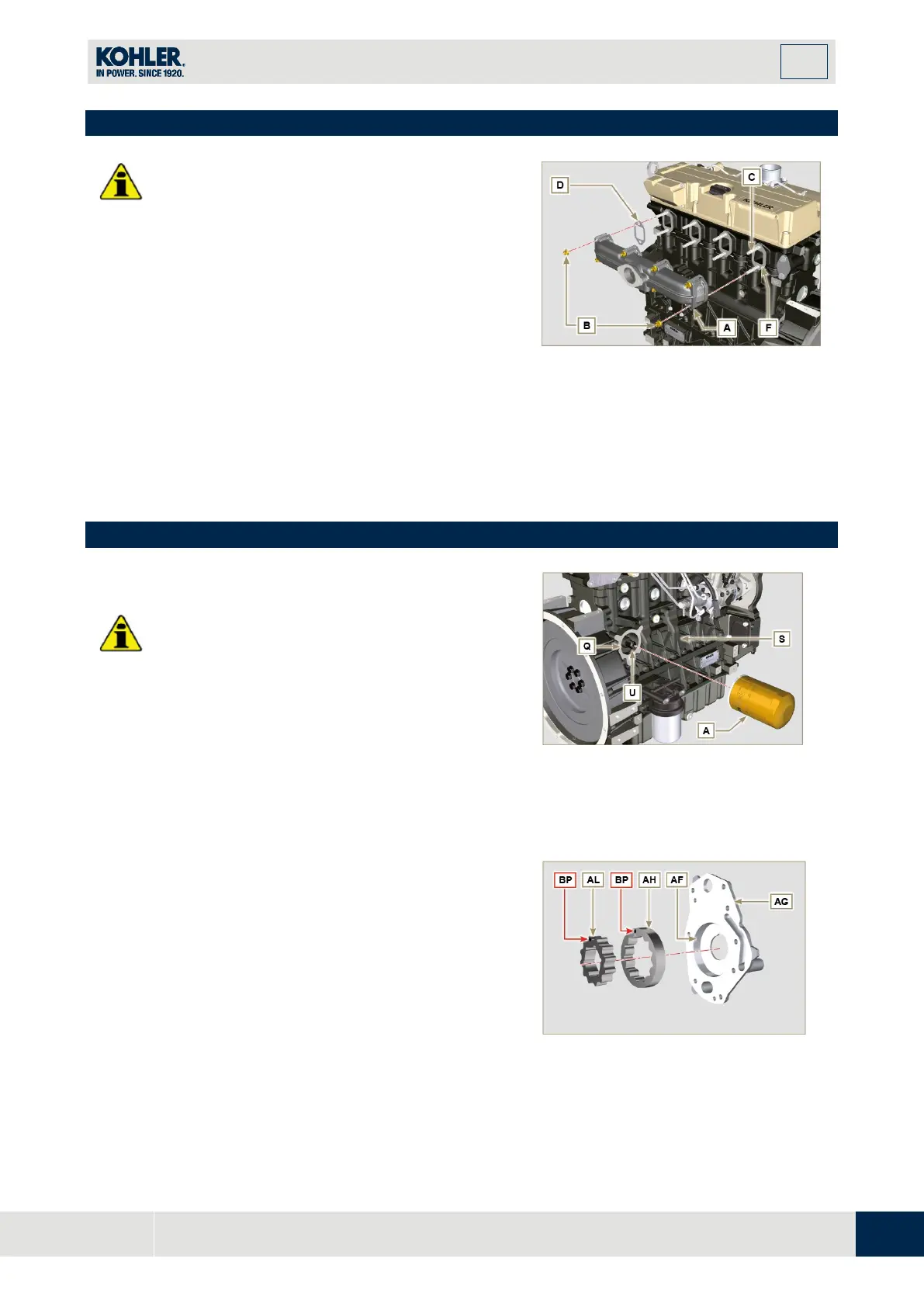

9.11 Lubrication circuit assembly

Important

•

In the event of mounting the fitting U on the

crankcase S, fix (15 Nm tightening torque) wi

th

Loctite 2701 on the thread.

1.

Check that the surface Q on crankcase S are fr

ee

f

rom impurities.

2.

Screw the cartridge A on the fitting U (tightening

torque at 15 Nm).

Fig 9.72

N

OTE:

Carry out the checks described in

Par. 8.7

before

proceeding with the following operations.

1.

Check that all contact surfaces between AL, AH

,

AF

, AG and AN are free of impurities – scratches -

dents.

2.

When assembling, do not use any type of gasket

between AG and AN.

3.

Thoroughly lubricate the seat of the rotors AF on

t

he oil pump crankcase AG and the two rotors AH

and AL.

Fig 9.73

Loading...

Loading...