INFORMATION ABOUT OVERHAULING

8

101

EN

•

The crankshaft and connecting rod must be

replaced every time they are assembled to prevent

seizure, as they are made of special lead-free

m

aterial.

•

The MAX allowed value of wear for A1 and A2 is

0.120 mm.

•

The MAX allowed value of wear for B1 and B2 is

0.120 mm.

•

To grind the crankshaft, a decrease in diameter of

t

he halfbearings and connecting rod is provided f

or

a

t 0.25 mm and 0.50 mm, to grind gudgeon pins

A1 and B1, measure the values of diameters A

2

an

d B2 by assembling the decreased half-

bearings, define the diameter to grind of pins A

1

an

d B1,

observing the clearance indicated in Tab. 8.5.

•

La Tab. 8.5 riporta i valori dimensionali solo per

i

c

omponenti nuovi.

Tab 8.5 Connecting rod and journal

diameter

REF.

(mm)

CLEARANCE

VALUE (mm)

A

0.035 - 0.085

A1

B

0.035 - 0.102

B1

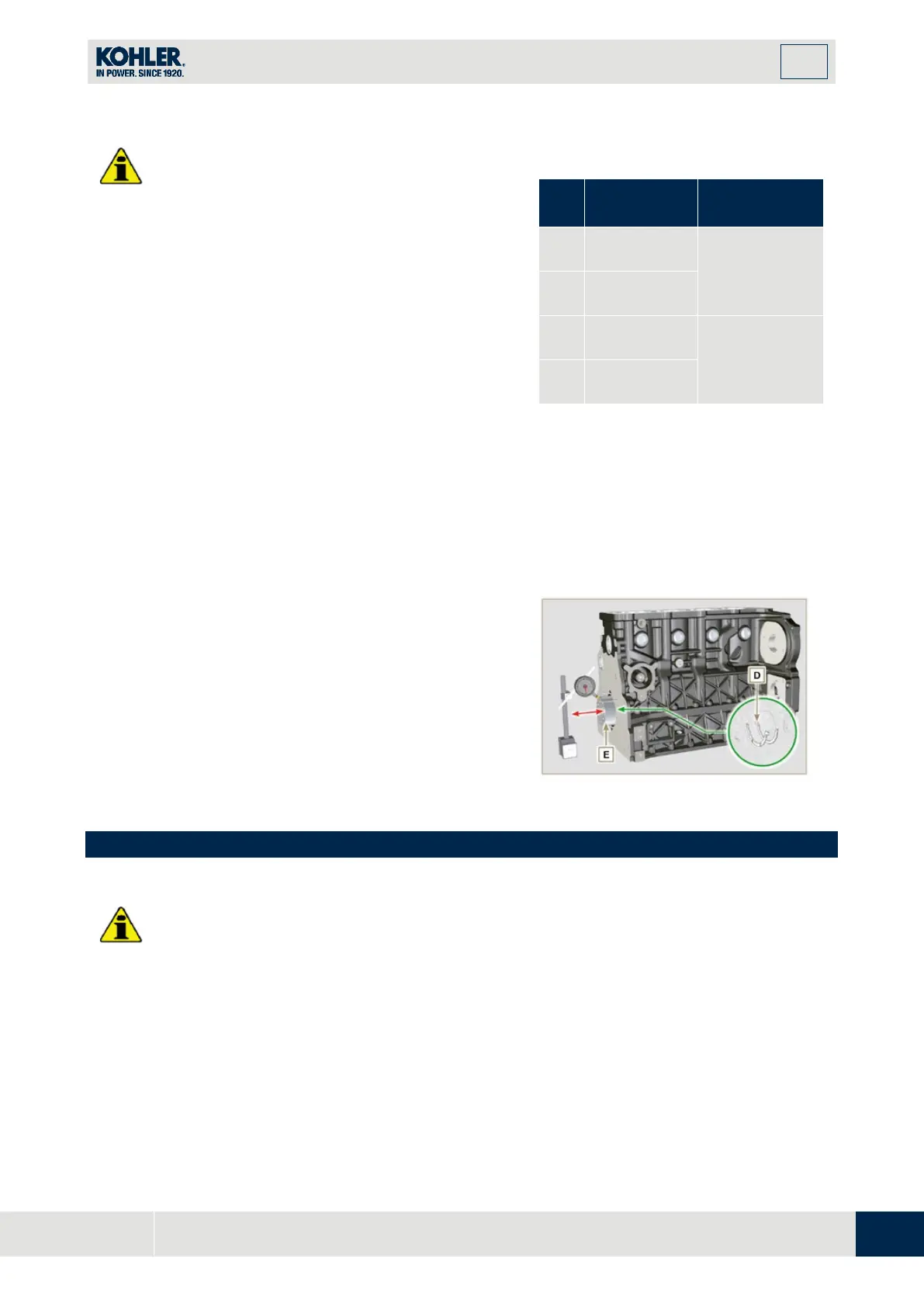

8.4.2 Checking the axial clearance of the crankshaft

P

erform the operations described in

Par. 9.3.5 and 9.3.6

.

Using a dial gauge, measure the axial shift of crankshaft

E

.

Axial shift must be a

MIN

of 0.18 mm and

MAX

0.38 mm..

If the values measured do not correspond, replace shoulder

rings

D

.

8.5 Connecting rod - piston assembly

Important

•

In case of replacement, the connecting rods and

pistons must always be replaced for all

cylinders.

Loading...

Loading...