INFORMATION ABOUT OVERHAULING

8

105

EN

8.6 Cylinder head

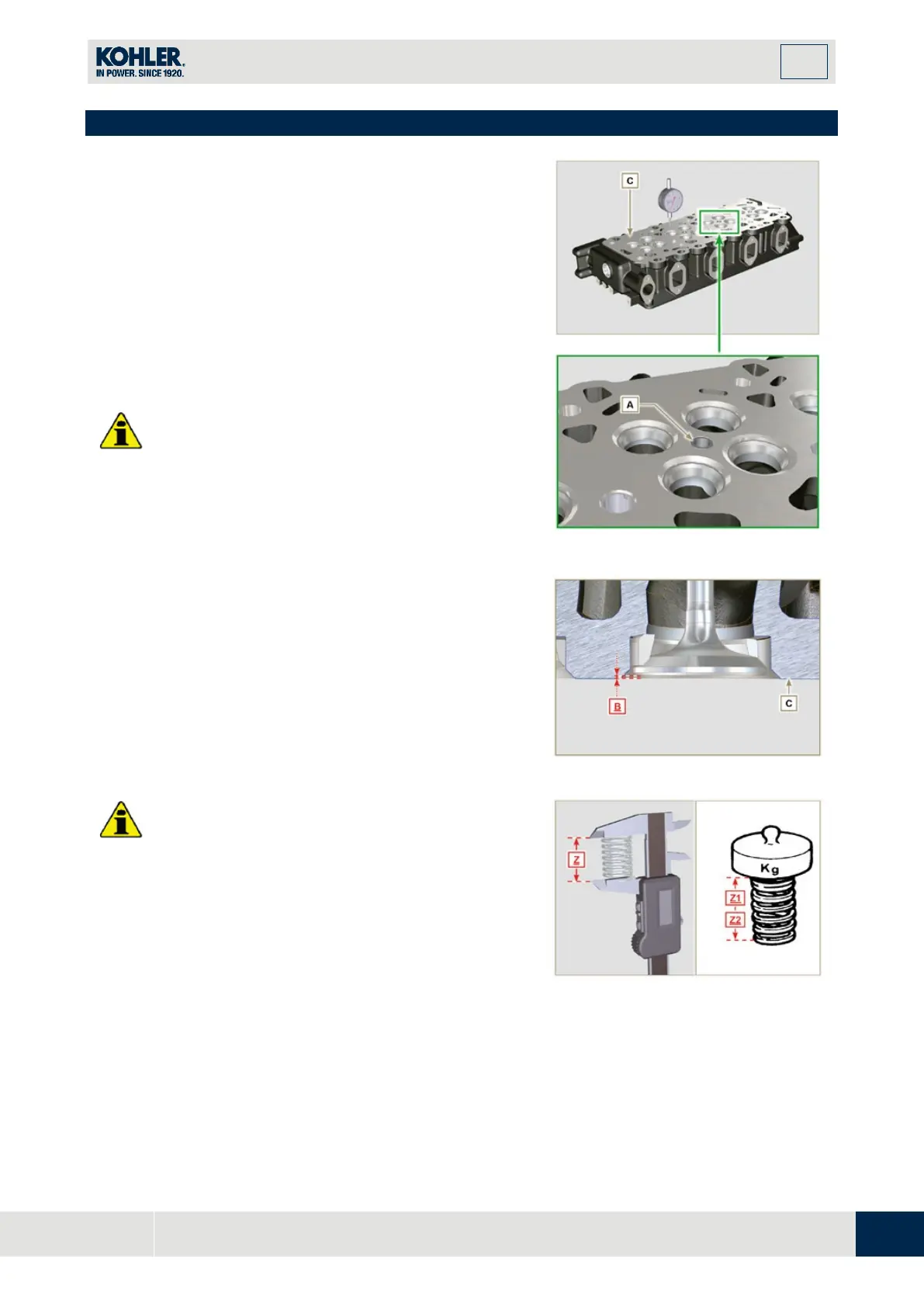

8.6.1 Flatness check

Put the cylinder head on a surface plate and, with a dial

gauge, check the flatness of surface C.

The MAX value of allowable irregularity of surface C is

0.10mm.

If the value is not observed, you are required to grind surface

C.

The MAX removal allowed is 0.20 mm.

Important

•

Grinding is to be performed with sleeves A of the

injectors assembled.

Thoroughly clean the valves and their seats with.

Measure indentation

B

of each valve with regard to the

cylinder head surface

C

, which is to be a

MIN

of 0.60 mm

and

MAX

of 0.85 mm.

The

B MAX

indentation allowed on worn components is 1.10

mm.

If the measured value does not correspond with the values

indicated, replace the worn component.

Important

•

The seats must be worked after driving to reach valu

e

B,

go to a rectification workshop for such operations.

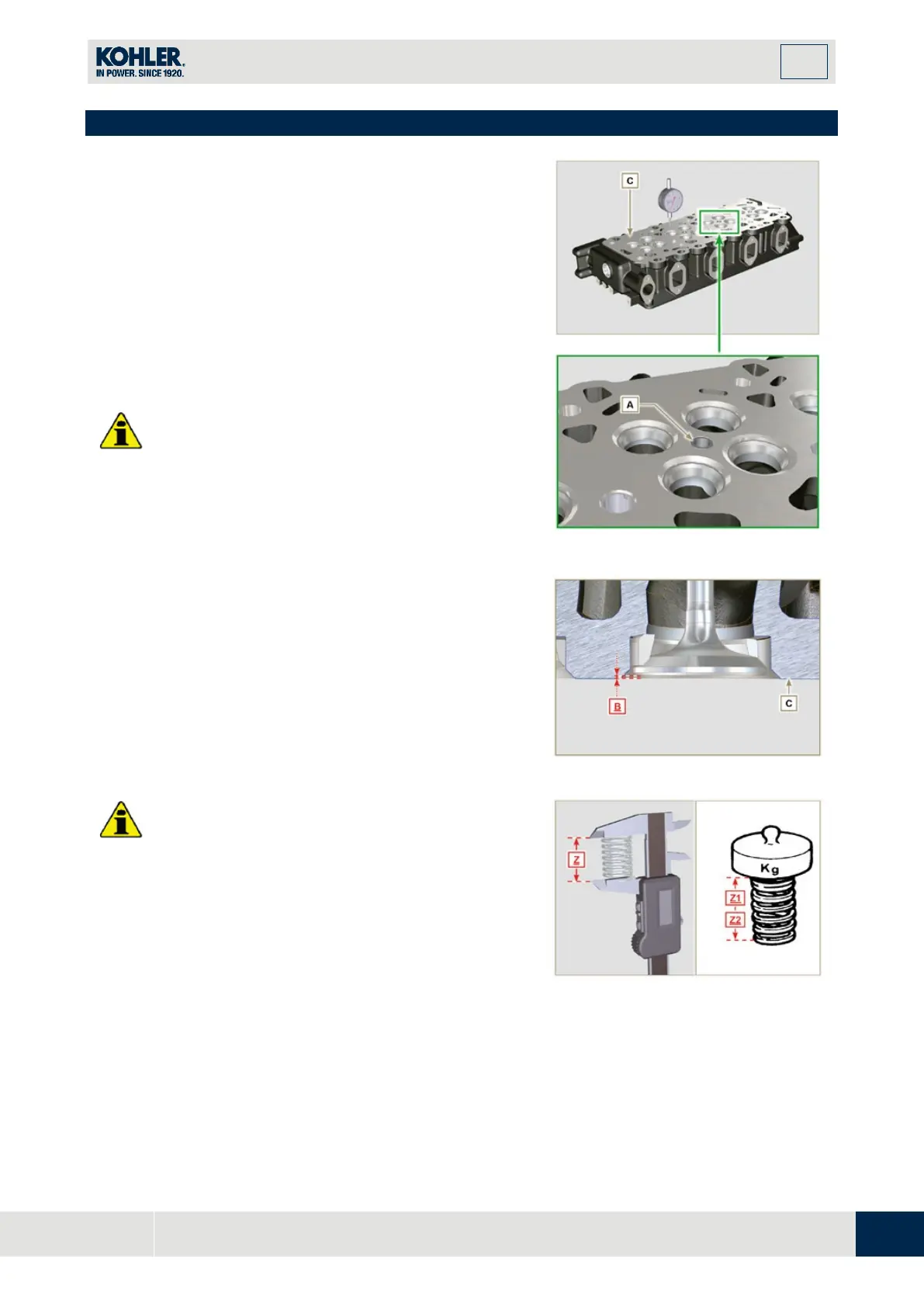

8.6.3 Valve springs

Using a dynamometer, subject the spring to two different

forces (in Tab. 8.9) and check that the length of the spring

corresponds to the values indicated in the table.

(

*1)

The code

ED0057551850-S

is installed from

S/N

4418801760

Fig 8.21

F

ig 8.22

Loading...

Loading...