9

ASSEMBLY INFORMATION

EN 118

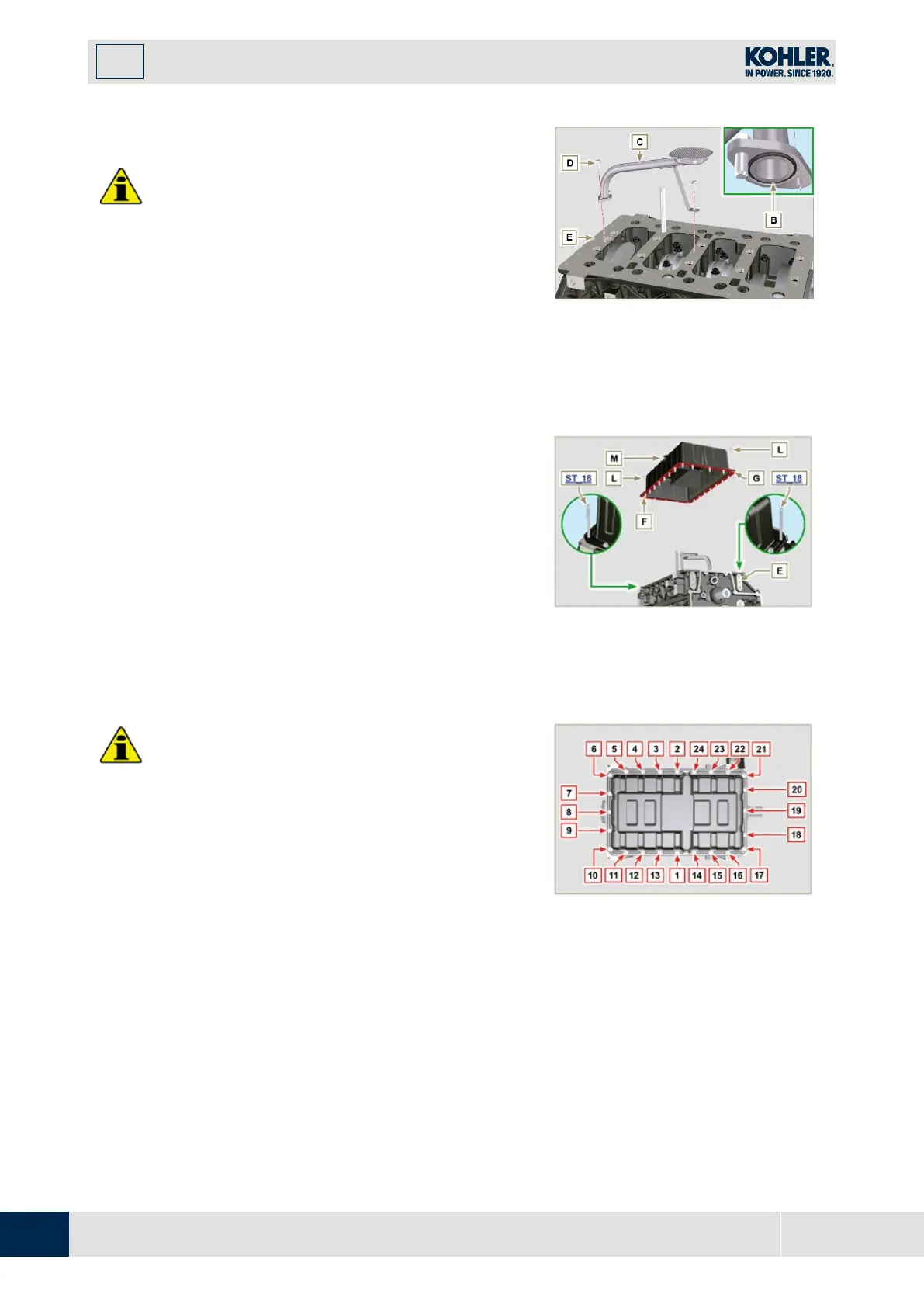

Important

•

It is mandatory to replace the gasket B after each

assembly.

•

Always replace capscrews D with new ones or

alternatively apply Loctite 2701.

1.

Insert the new gasket B in the seat of the oil suctio

n

h

ose flange D.

2.

Secure the hose C on the crankcase E with the

screws D (tightening torque 10 Nm).

Fig 9.24

1.

Ensure that the contact surfaces F of the oil sump G

and the crankcase E are completely clean.

2.

Apply a bead of approx. 2.5 mm of sealant (Loctite

5660) on the surface F of the oil sump G.

3.

Rotate the crankshaft clockwise ST_34 tool bringin

g

r

eference X upwards.

NOTE: During the positioning phase of reference X,

check that cylinder N° 1 is in compression phase

(intake and exhaust valves of cylinder N° 1 must be in

closing position).

Fig 9.25

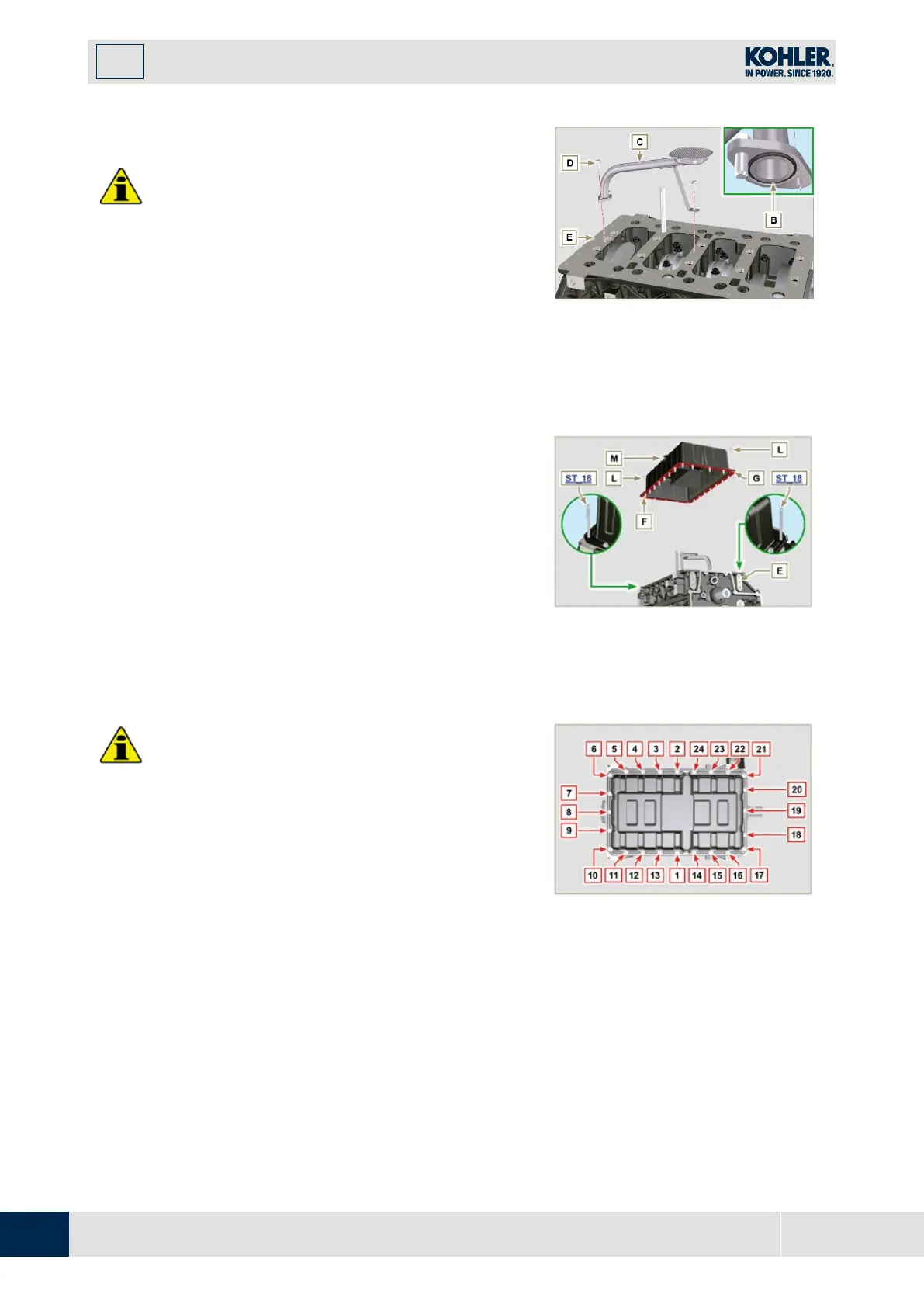

•

Tighten the screws L, strictly following the sequence

and tightening torque indicated.

4.

Tighten the screws L following the sequen

ce

i

ndicated (tightening torque 25 Nm).

5.

Remove the two studs ST_18 with the appropriate

screws (tightening torque 25 Nm)

6.

After tightening all of the screws, loosen screw n°1

and retighten it to the torque value specified in step

4.

7.

Check that the oil drain plugs M are tight (tightening

torque 35 Nm).

Fig 9.26

Loading...

Loading...