11

INFORMATION ABOUT OPTIONAL

COMPONENTS

EN 174

4.

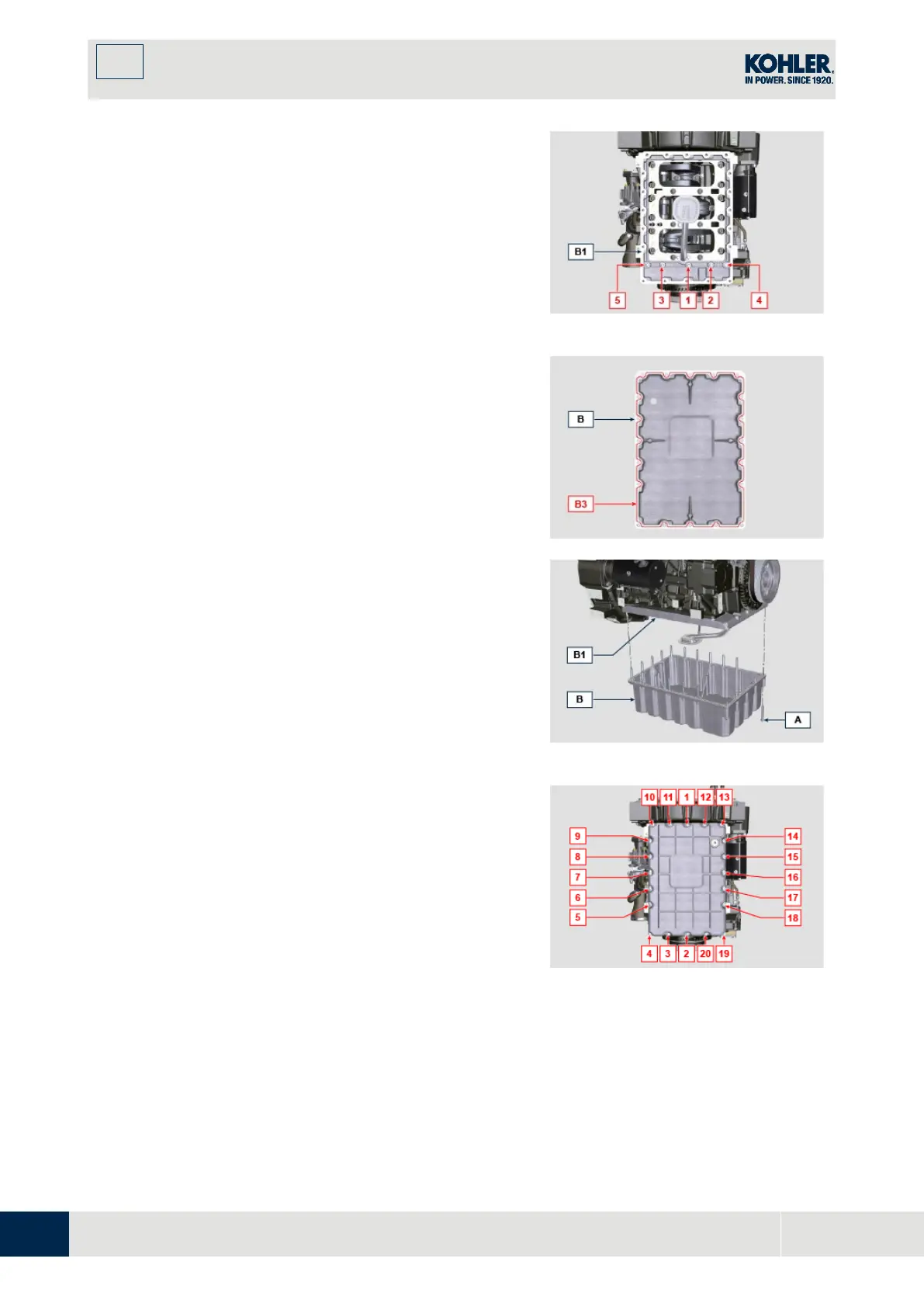

To fix the sump B1 , tighten the screws A1 by strictl

y

following the order indicated in the Fig. 11.83

(tightening torque of 25 Nm ).

5.

Loosen the screw 1 again and tighten it to 25 Nm .

Fig. 11.83

6.

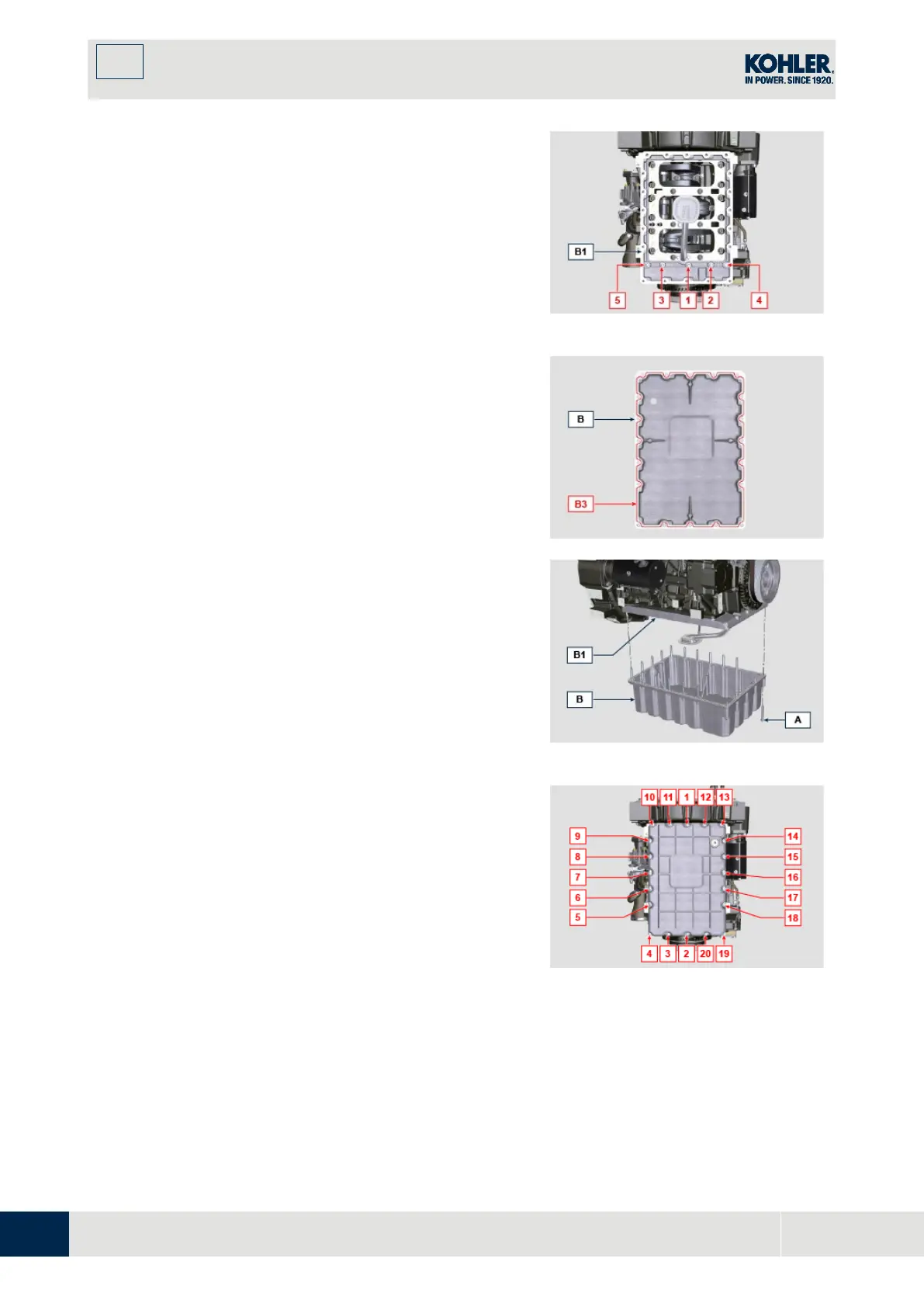

Apply a bead of approx. 2.5 mm of sealant ( Loctite

5660 ) inside the channel B3 of the oil sump B .

7.

Position the oil sump B on the oil sump B1 flange at

the fixing holes (use the tool ST_18 ).

8.

Screw the screws A in the fixing holes.

Fig. 11.84

9.

To fix the sump B , tighten the screws A by strictl

y

f

ollowing the order indicated in the Fig. 11.85

(tightening torque of 25 Nm ).

10.

Loosen the screw 1 again and tighten it to 25 Nm .

Fig. 11.85

Loading...

Loading...