IX - 15

Maintenance

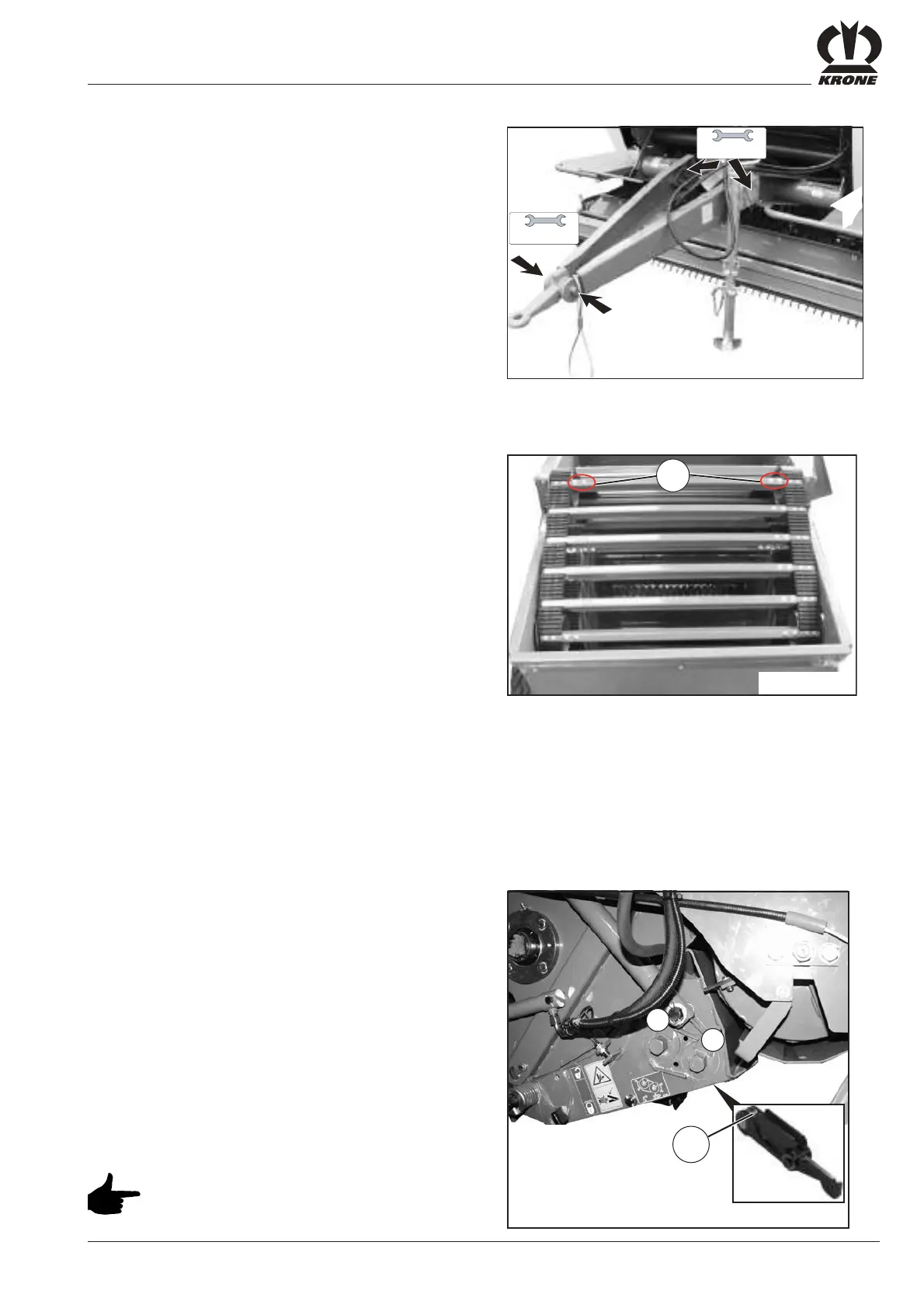

9.3.10 Drawbar

• Tighten the bolts after the first 10 operating hours.

• Check the bolts every 50 operating hours.

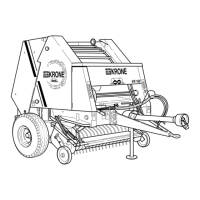

9.3.11 Screw connections on front and rear

floor conveyors

• Set the torque wrench on 40 Nm

• Tighten nuts of screw connection (1). In case the

tightening torque is not achieved, loosen the screw

connection (1).

• Check the threadings of the screw and nut; in case of

damages use new parts.

• Insert the screw connection (1) "high-strength" with

loctite and tighten with 70 Nm.

9.3.12 Novo Grip belt on floor conveyor

The fraying of the Novo Grip belt is a new

procedure, since the belt is cut laterally. Check the

belts on a regular basis and cut the fringes if required.

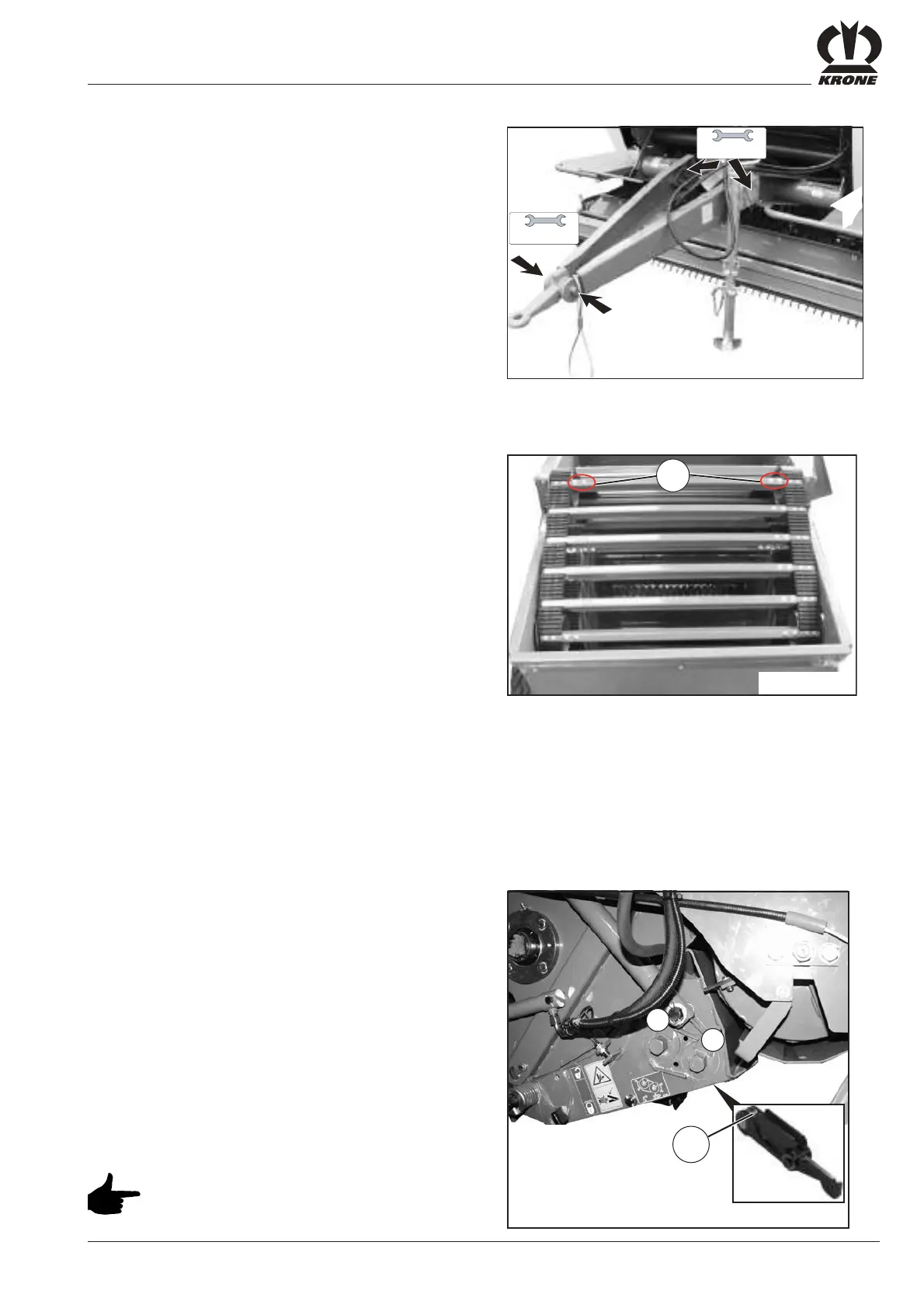

9.3.13 Checking the safety rollers of single

blade locking device

The safety rollers (1) on the levers of the single blade

locking device must turn slightly when

they are turned on (tensioning of safety springs with

multipurpose key after blades are

installed). If they do not, the result will be an increased

amount of force applied to select blades.

The individual knife retention will not work properly

(increased blade breakage).

• To prevent this,lubricate the safety rollers (1) if they

no longer turn easily, but in any case once a year.

To lubricate the safety rollers, use an EP

long-term grease NLGI 2 order No.

926 045 0 (400 grams).

730 Nm

210 Nm

RPN00049

RPN00043_02

1

A

B

RPN00079

1

Loading...

Loading...