141 of 206

BA KR 6, 16 F, KR C4 12.10.07 en

10.5 Lubrication, in--line wrist IW 6 II

Information!

Section 10.2 of this chapter must be observed!

Warning!

Turn the main switch on the robot control cabinet to “OFF” and secure it with a

padlock to prevent unauthorized persons from switching it on again.

Notice!

Store used oil and grease in accordance with regulations and dispose of them

with minimum environmental impact.

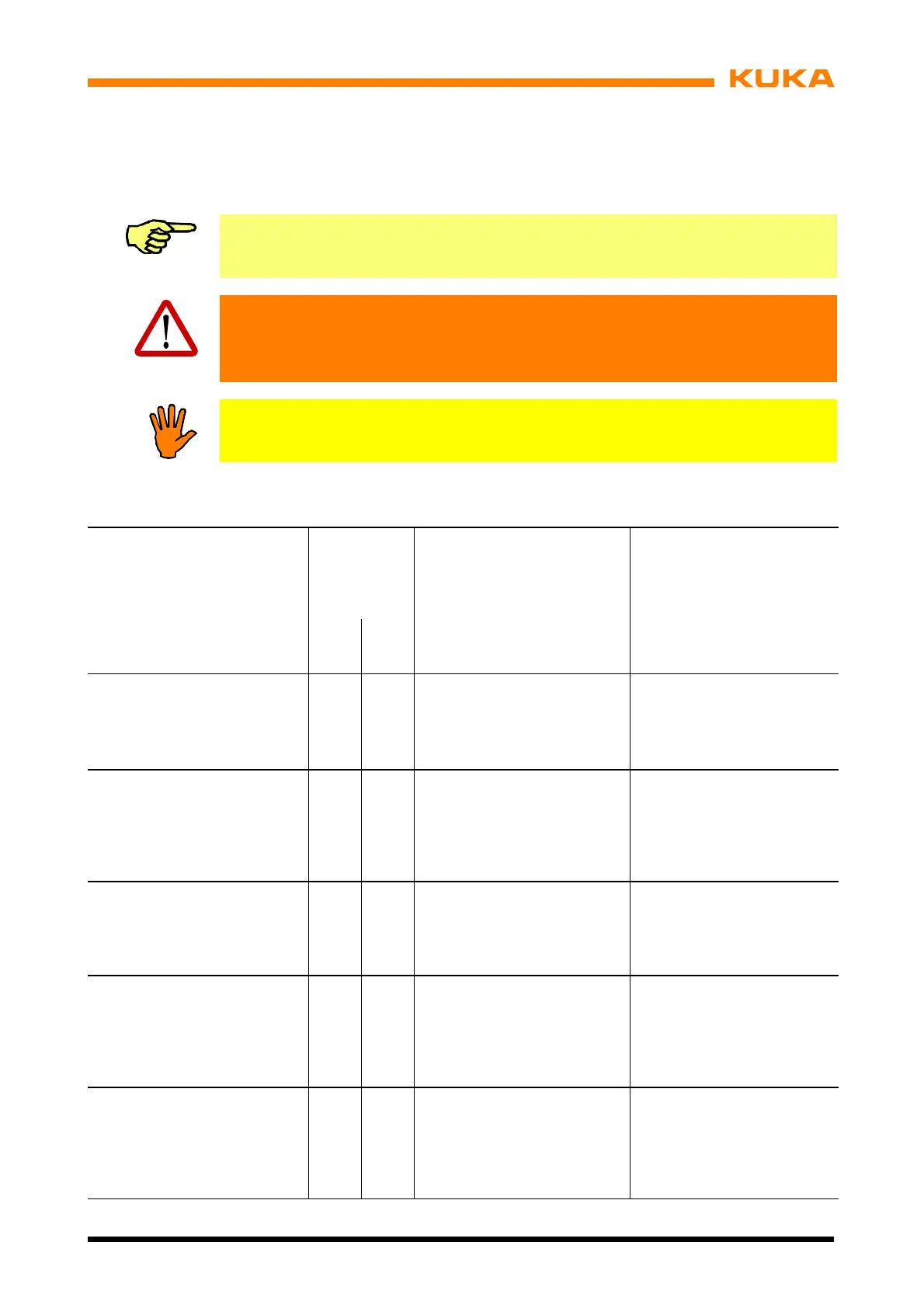

D “Lubrication” table

Maintenance point

(see Fig. 104)

Maintenance

interval

(hours)

Activity

Lubricant

Manufacturer

Amount

KUKA Art. no.

Note

10 00

20 000

Gear block A4

D

Oil change

Optigear Synthetic RO 150

Castrol, approx. 0.10 l

1)

KUKA Art. no.

00--144--898

Change oil as described in

Section 10.5.1.

O--ring A4

D

Lubricate

Optigear Olit CLS

Optimol, approx. 10 g per

O--ring

KUKA Art. no.

83--087--241

Lift O--rings out of grooves.

Remove old grease.

Grease O--rings with brush

and fit them back into

grooves.

Gear block A5/6

D

Oil change

Optigear Synthetic RO 150

Castrol, approx. 0.10 l

1)

KUKA Art. no.

00--144--898

Change oil as described in

Section 10.5.1.

~

O--ring A5

D

Lubricate

Optigear Olit CLS

Optimol, approx. 10 g per

O--ring

KUKA Art. no.

83--087--241

Lift O--ring out of groove.

Remove old grease.

Grease O--ring with brush

and fit it back into groove.

O--ring A6

D

Lubricate

Optigear Olit CLS

Optimol, approx. 10 g per

O--ring

KUKA Art. no.

83--087--241

Lift O--ring out of groove.

Remove old grease.

Grease O--ring with brush

and fit it back into groove.

1) The oil quantities specified are the actual amounts of oil in the gear unit at first filling.

Loading...

Loading...