171 of 206

BA KR 6, 16 F, KR C4 12.10.07 en

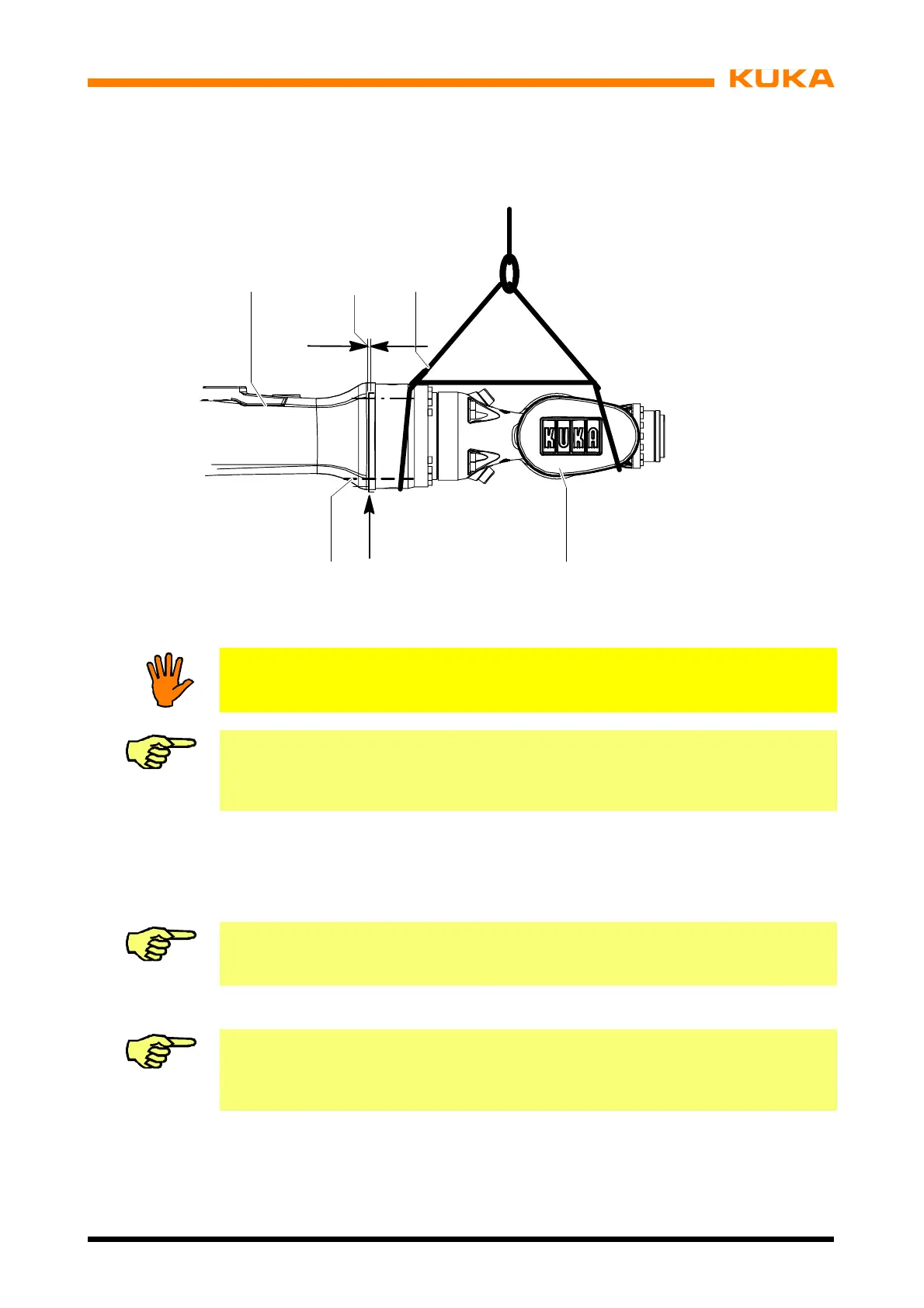

2

3

4

5

1

Fig. 119 Removal, installation of in--line wrist

Notice!

The in--line wrist may not be further dismantled.

Information!

If the in--line wrist is not to be reinstalled, it must be protected against corrosion before

being put into storage.

D Installation

(1) Remove all protective coatings and oil from new in--line wrist, if applicable.

Information!

Clean the shaft toothing before installation and lightly grease it with Microlube GL 261.

(2) Install the in--line wrist by carrying out the removal instructions in reverse.

Information!

When installing a new in--line wrist, it must be ensured that axes 4, 5 and 6 are in their

zero positions.

(3) Tighten the 16 M6x90--10.9 Allen screws (Fig. 119/5) with a torque wrench in diagonally

opposite sequence, increasing the tightening torque M

A

in several stages to the speci-

fied value (M

A

= 12.5 Nm).

(4) Carry out zero adjustment on axes 4, 5 and 6 (see Operating Handbook, Software

KR C4, Chapter “Start--up”, Section “Robot Mastering/Unmastering”).

Loading...

Loading...