Chapter 7 Alarm

136

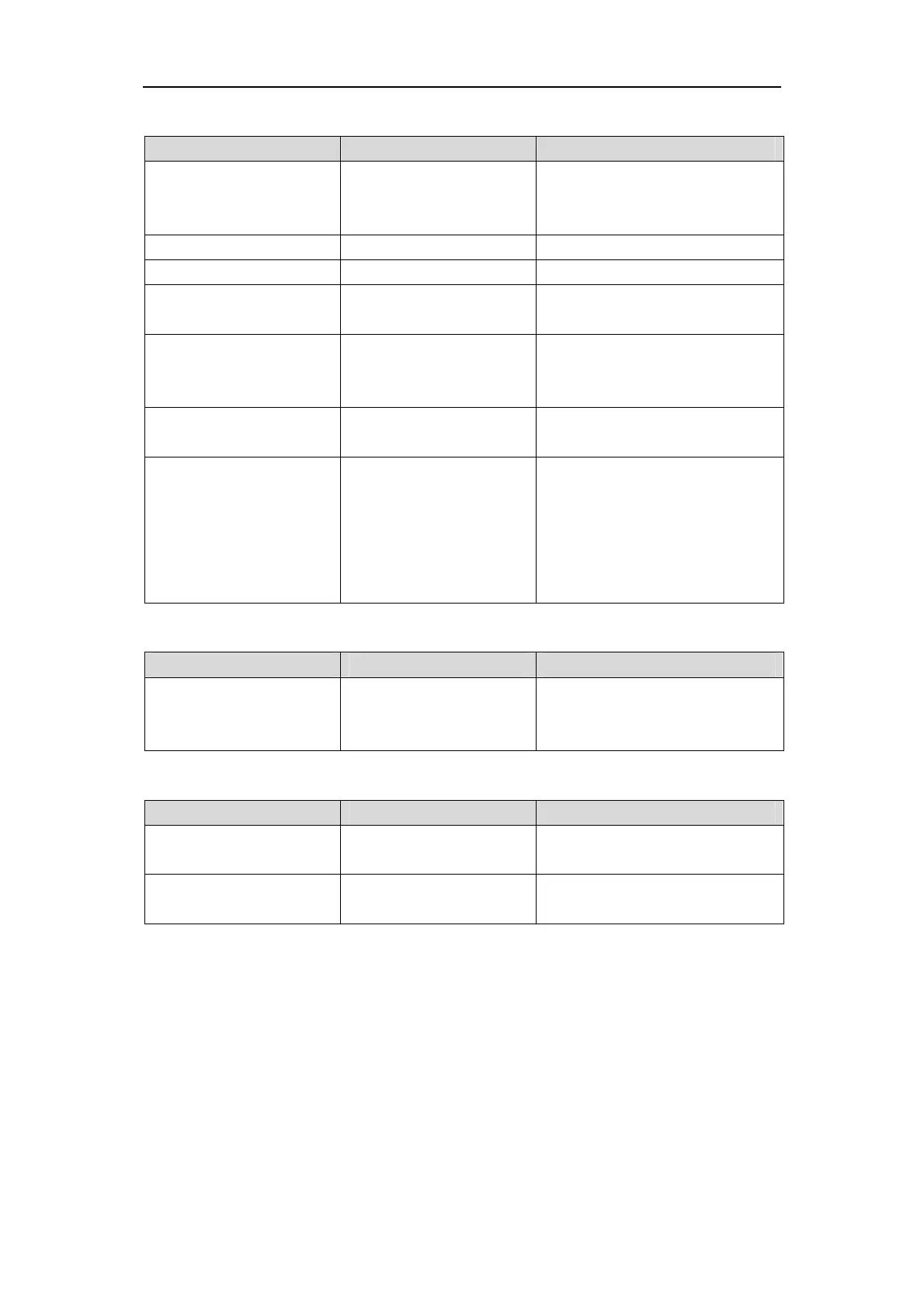

Err 4 (Position deviation)

Potential cause Check Handle

Servomotor U 、 V 、 W

connection is not correct

Check U、V、W wiring

Correct U、V、W wiring. The U、V、

W must connect with servo driver

terminal U、V、W correspondently.

Encoder zero point changes Check the encoder zero point Adjust the zero point of encoder again.

Encoder wiring error Check the encoder wiring Correct connection

The servomotor is blocked

Check the servomotor shaft and

its mechanical connection

Repair.

Command pulse frequency is

too high

Check the input frequency and

pulse frequency doubling

parameters

Lower input frequency

Adjust the pulse frequency doubling

parameters

The position loop gain is too

small

Check parameters P009, P013 Increase the position loop gain

Torque is not enough big Check torque

Increase the torque limit.

Increase smooth filtering time for

position command.

Reduce load.

Replace the servo driver and

servomotor with bigger ones.

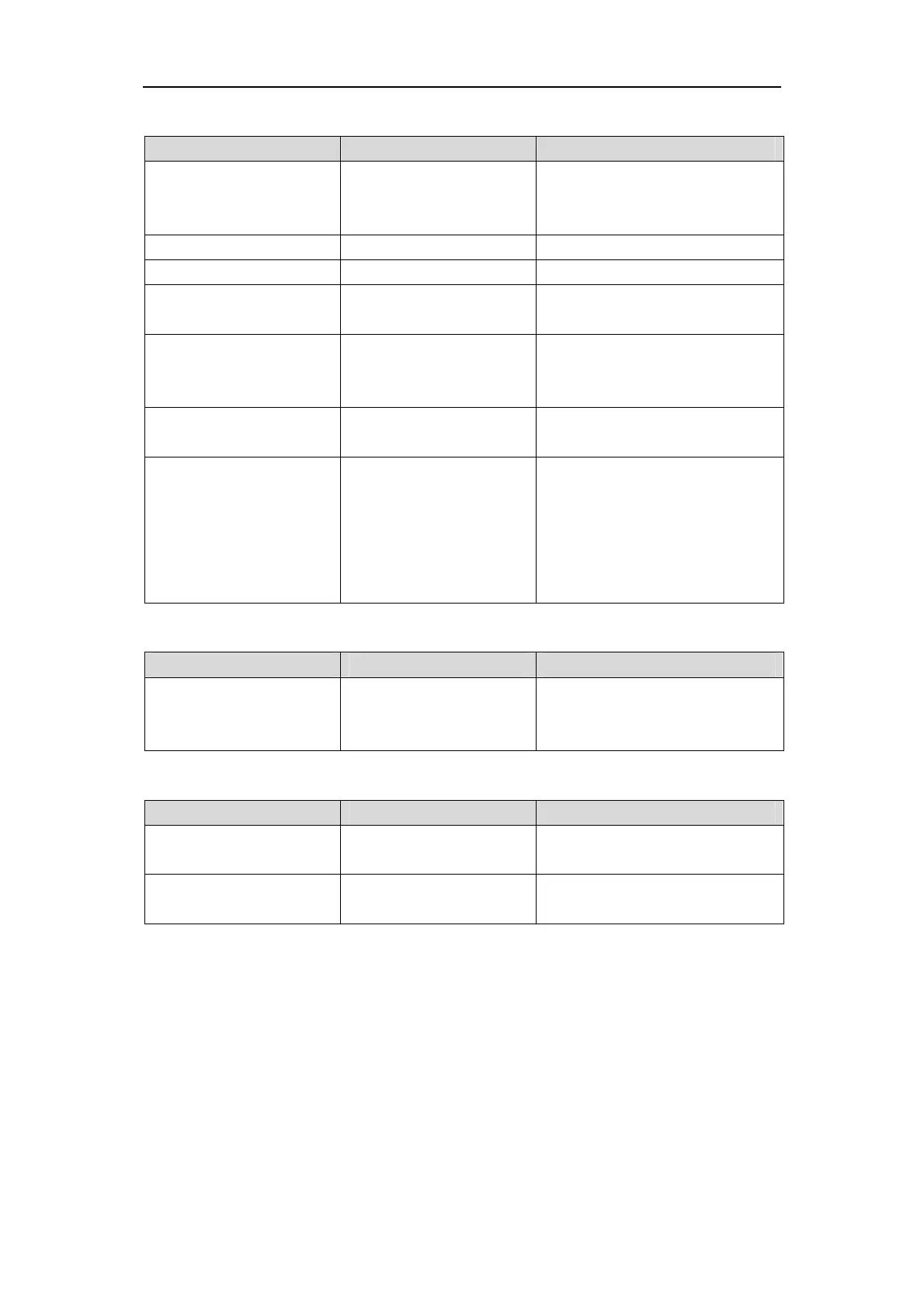

Err 7 (Drive inhibition abnormal)

Potential cause Check Handle

When the servo enable,

CCWL、CWL drive forbidden

input are invalid

Check CCWL、CWL wiring

Correct input CCWL、CWL signal.

If not use CCWL、CWL signal can

shield it by setting parameter P097.

Err 8 (Overflow of position deviation counter)

Potential cause Check Handle

The servomotor is blocked

Check the servomotor shaft and

its mechanical connection

Repair.

The command pulse is

abnormal

Check command pulse

Loading...

Loading...