Chapter 4 Running

48

4.3

Speed control mode

See the section "6.3.2 AC4: Motion control with central interpolation and speed setting

interface" for instructions.

The speed control mode is used in applications where precise speed control is required,

such as weaving machines, drilling machines, CNC machines. The position control can also be

constituted by the upper device.

4.3.1

Speed control mode parameter setting

Parameter setting:

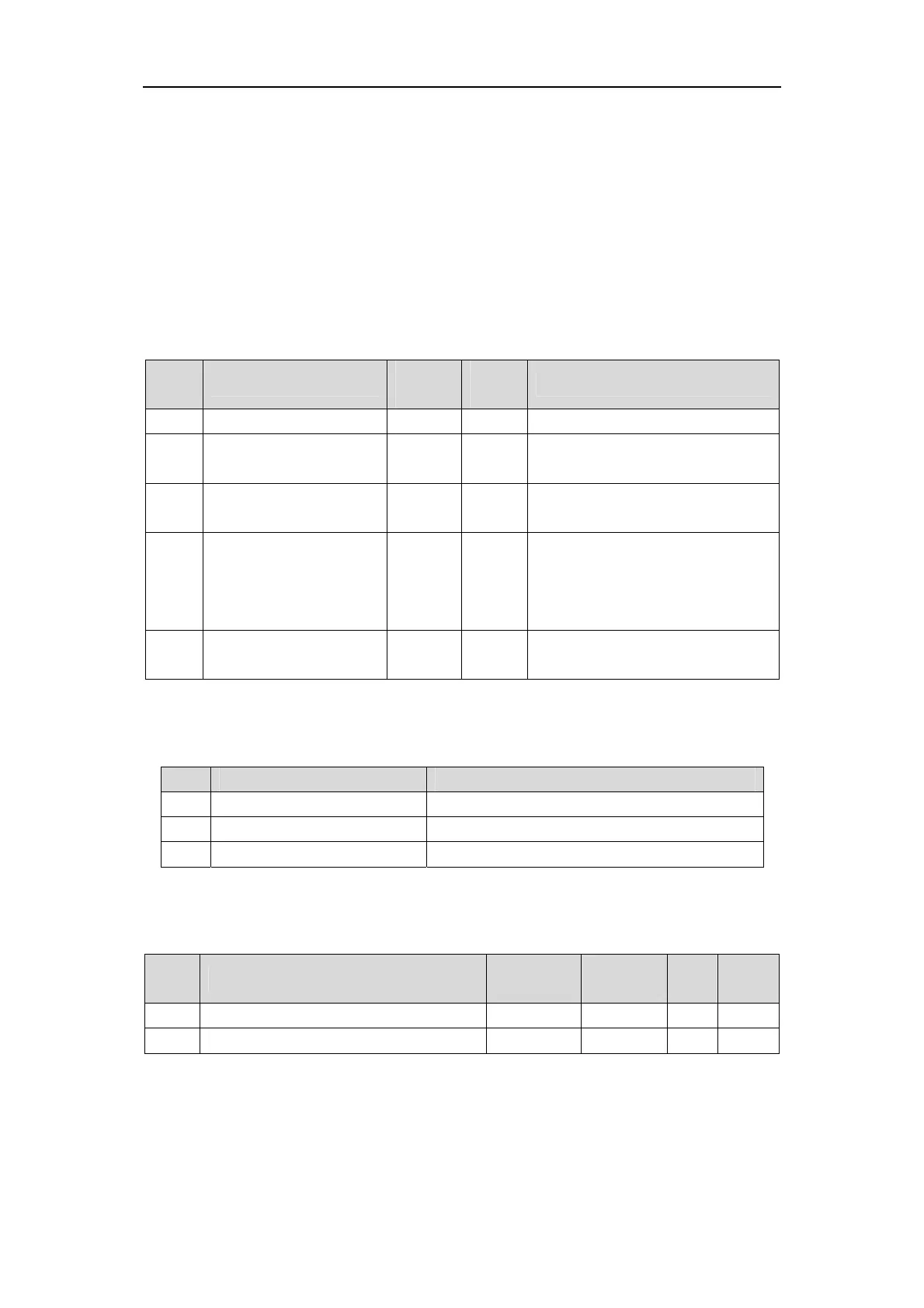

Para

meter

Name

Setting

value

Default

value

Parameter explanation

P025 Speed command source 0 0 Reserved

P060

Speed command

acceleration time

suitable 0

P061

Speed command

deceleration time

suitable 0

P097 Ignore driver prohibition 3 3

Use Forward Drive Inhibition

(CCWL) and Reverse Drive

Inhibition (CWL). If set to ignore,

can not connect to CCWL, CWL.

P304 PROFINET mode switch 1 1

0: Normal mode;

1: PROFINET mode.

4.3.2

Speed command source

The speed command has several different sources and is set by parameter P025:

P025 Instruction Explication

3 JOG speed command Set when doing a JOG operation

4 Keyboard speed command Set for keyboard speed regulation (Sr) operation

5 Demonstrate speed command Setting for speed control demonstration

4.3.3

Acceleration and deceleration

Acceleration and deceleration are related to the following parameters:

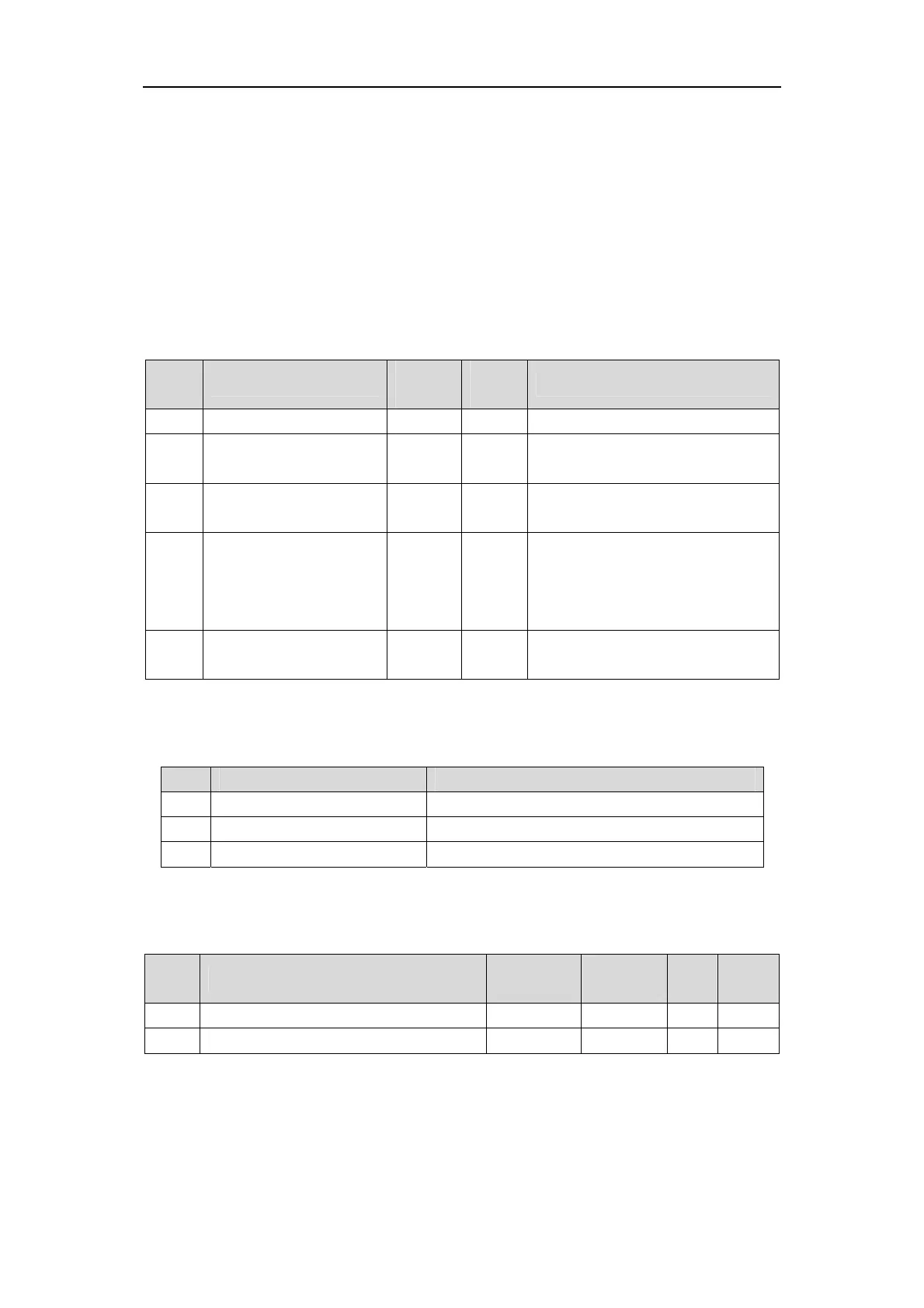

Para

meter

Name Range

Default

value

Unit Usage

P060 Speed command acceleration time 0~30000 0 ms S

P061 Speed command deceleration time 0~30000 0 ms S

Loading...

Loading...