Chapter 2 Wiring

18

2.1.2

Wiring instructions

Wiring Notes:

According to electric wire specification, use the wiring materials.

The control cable length should be less than 3 meters and the encoder cable length 20

meters.

GL series: Check that the power supply and wiring of L1、L2、L3 and L1C、L2C

terminals are correct. Please do not connect to 380V power supply.

GH series: Check L1、L2、L3 and 0V、24V power supply and connection are correct.

The output terminals(U、V、W) must be connected with the servo motor connections(U、

V、W) correspondently, otherwise the servo motor will stop or over speed. However, by

exchanging three-phase terminal cannot cause the motor to reverse; this point is different

from an asynchronous motor.

Earthed wiring must be reliable with a single-point connection.

Pay attention to the correct direction of freewheel diode which is connected with the relay

at the output terminal, otherwise can cause the output circuit breakdown.

In order to protect the servo driver from noise interference that can cause malfunction,

please use an insulation transformer and noise filter on the power lines.

Wiring the power lines (power supply line, main circuit lines, etc.) at a distance above

30cm from the control signal wires, do not lay them in one conduit.

Install a non-fuse circuit breaker that can shut off the external power supply immediately

for in case of the servo driver fault.

2.1.3

Electric wire specifications

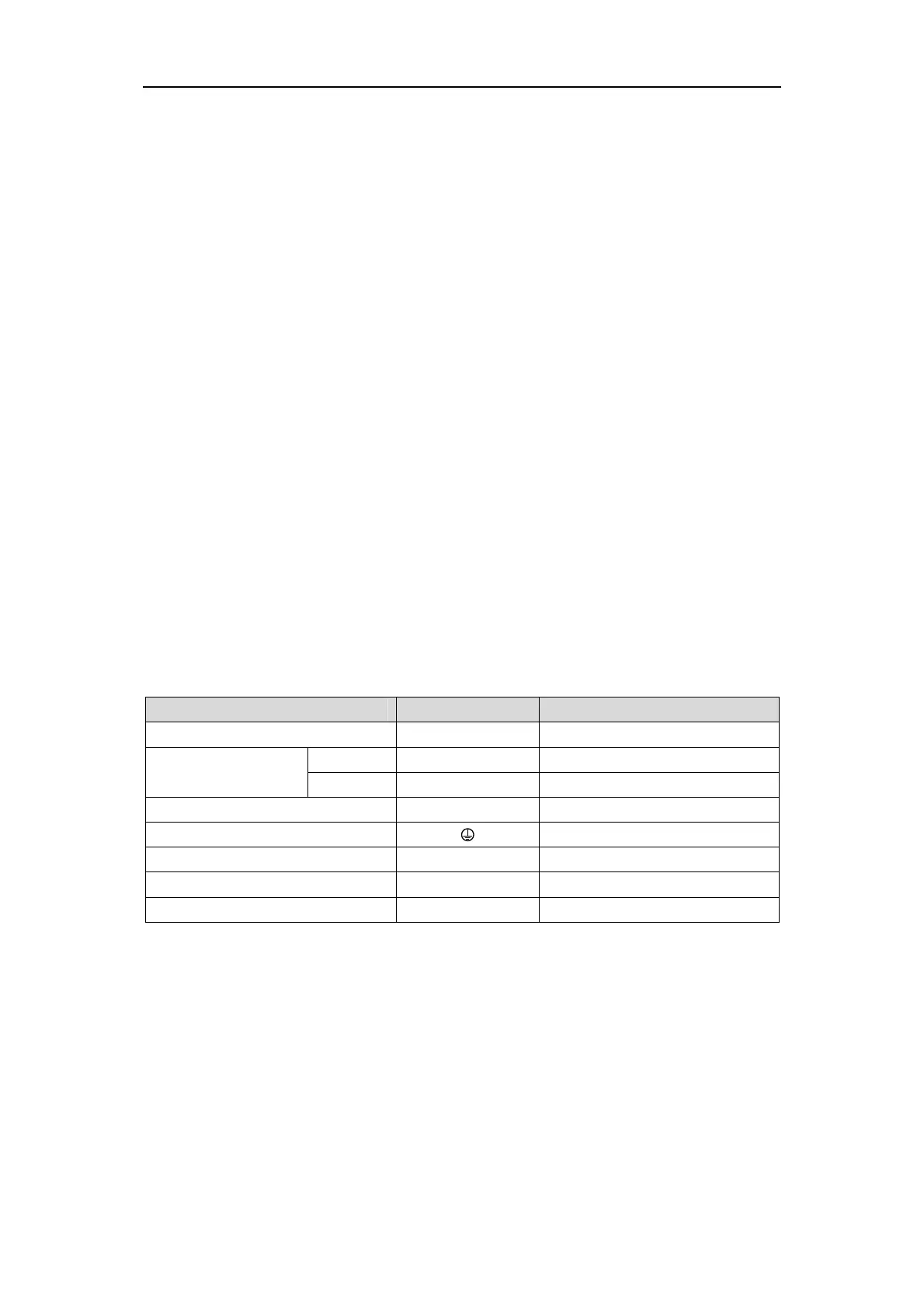

Connect terminal Symbol Wire specification

Main power supply L1、L2、L3 0.75~10mm

2

Control power supply

GL series L1C、L2C 0.75~1.0mm

2

GH series 24V、0V 0.75~1.0mm

2

Servomotor U、V、W 0.75~10mm

2

Ground 0.75~4mm

2

Control signals X1 ≥0.14mm

2

(AWG26),shielded

Encoder signals X2 ≥0.14mm

2

(AWG26),shielded

Brake resistor Terminal P、B1/P、B 1.5~4mm

2

Must use a twisted pair wire cable for the encoder signal wiring. If the encoder signal cable

is too long (>20m), in which the encoder power supply can be insufficient, may use multi-wire

or thick wire for the power supply wiring.

Loading...

Loading...