103

Selection and protection of a motor

(6) PTC thermistor input using terminal AU (PTC signal)

Built-in PTC thermistor of the motor can be input to the PTC signal (AU terminal).

For the terminal used for PTC signal input, assign the function by setting "63" in Pr. 184 AU terminal function selection

and also set the AU/PTC switchover switch to the PTC terminal function. (The initial setting is the AU terminal

function.)

If a motor overheat state is detected for more than 10s according to the input from the PTC thermistor, the inverter

shuts off the output and outputs the PTC thermal fault signal (E.PTC).

(7) PTC thermistor input using terminal 2 (Pr. 561)

PTC thermistor input connection example

The input specifications of the PTC thermistor

are shown on the right.

Motor Temperature PTC Thermistor Resistance Value ()

Normal 0 to 500

Boundary 500 to 4k

Overheat 4k or higher

CAUTION

When the PTC signal was not assigned to Pr. 184 and the AU/PTC switchover switch was set to the PTC terminal function, the

function assigned to the AU terminal is always OFF. Reversely, when the PTC signal was assigned to Pr. 184 and the AU/PTC

switchover switch was set to the AU terminal function, a PTC thermal error (E.PTC) occurs since the function is always in a

motor overheat state.

When you want to input a current, assign the AU signal to the other signal.

Changing the terminal assignment using Pr. 178 to Pr. 189 (input terminal function selection) may affect the other functions. Set

parameters after confirming the function of each terminal.

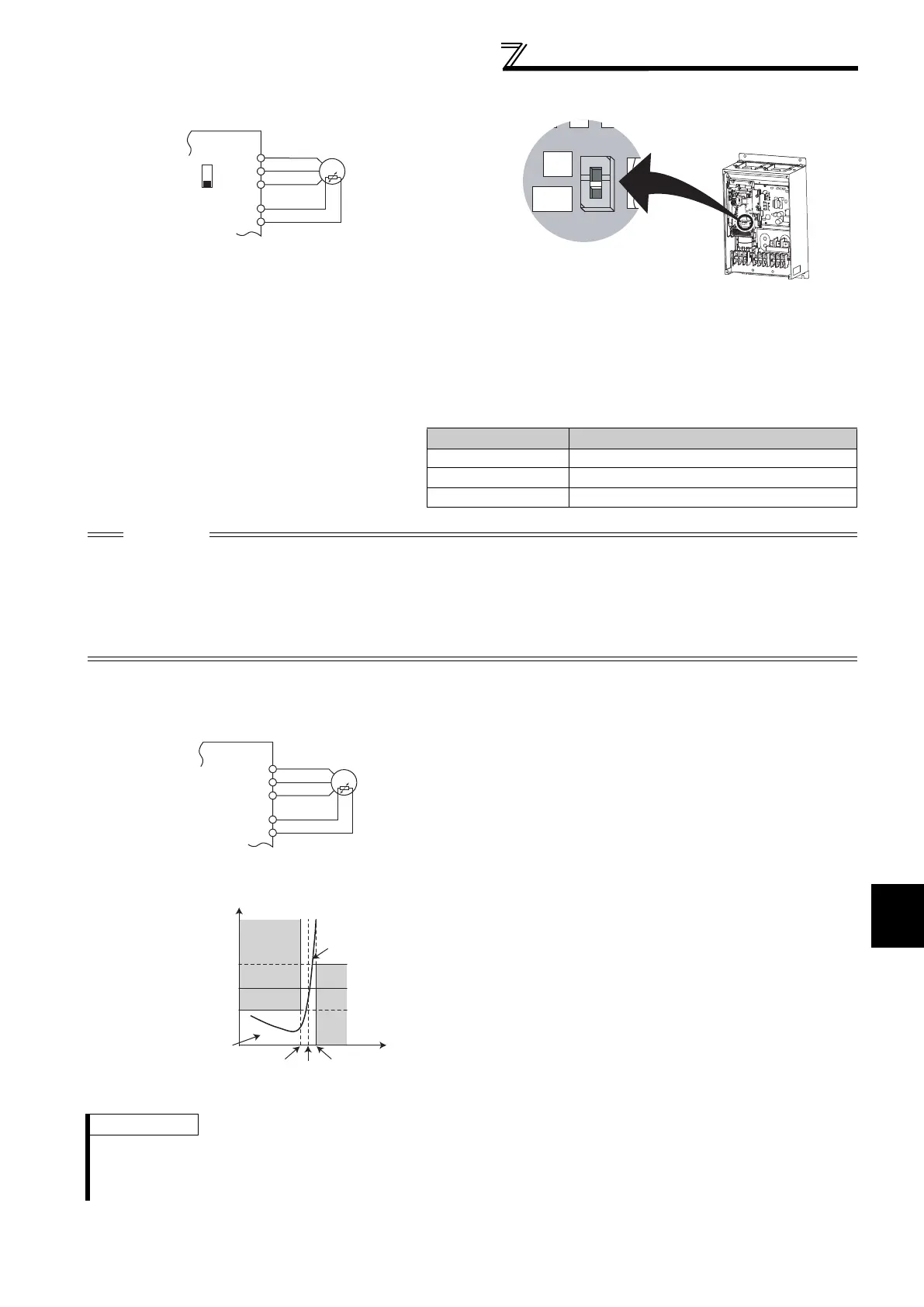

PTC thermistor input connection

• Terminal 2 and terminal 10 are available for inputting of

motor built-in PTC thermistor output. When the PTC

thermistor input reaches to the resistance value set in

Pr. 561 PTC thermistor protection level, inverter outputs PTC

thermistor operation error signal (E.PTC) and trips.

To use terminal 2 as a PTC thermistor input, set voltage/

current input switch of terminal 2 to OFF (initial setting),

and set the input specification of terminal 2 to 0 to 5V

input (Pr. 73 Analog input selection = "1 (initial value), 3, 5,

11, 13, or 15" ).

• Check the characteristics of the using PTC thermistor,

and set the resistance value within a protection providing

temperature TN, just around the center of R1 and R2 in a

left figure. If the Pr. 561 setting is closer to R1 or R2, the

working temperature of protection goes higher (protection

works later), or lower (protection works earlier).

• PTC thermistor resistance can be displayed in operation

panel (FR-DU07), parameter unit (FR-PU07), or RS-485

communication when PTC thermistor protection is active

(Pr. 561 "9999").

PTC thermistor characteristics

REMARKS

• When using terminal 2 as PTC thermistor input (Pr. 561 "9999"), terminal 2 is not available for analog frequency command. Also

unavailable when using terminal 2 for PID control. Input the set point using Pr.133 or via communications.

• For the power supply terminal of PTC thermistor input, do not use a power supply other than terminal 10 (external power supply, etc).

Otherwise the PTC thermistor will not work properly.

Inverter

U

AU

PTC

V

W

AU(PTC)

Motor

SD

Inverter

AU/PTC switchover switch

Factory-set to "AU".

Set to the "PTC" position to

validate the PTC signal input.

Inverter

U

V

W

10

2

Moto

R2

R1

Pr. 561

TN

TN+ΔTTN-ΔT

Thermistor

temperature

TN: Rated operational temperature

Thermistor

resistance

Thermistor curve

Temperature-resistance

existing range

Loading...

Loading...