266

PID control

<Set point input calibration>

1) Setting with terminal 2 input

1. Apply the input voltage of 0% set point setting (e.g. 0V) across terminals 2 and 5.

2. Enter in C2 (Pr. 902) the frequency which should be output by the inverter at the deviation of 0% (e.g. 0Hz).

3. In C3 (Pr. 902), set the voltage value at 0%.

4. Apply the voltage of 100% set point (e.g. 5V) to across terminals 2 and 5.

5. Enter in Pr. 125 the frequency which should be output by the inverter at the deviation of 100% (e.g. 50Hz).

6. In C4 (Pr. 903), set the voltage value at 100%.

2) Setting with Pr. 133

When both or one of C42 (Pr. 934) and C44 (Pr. 935) is "9999".

For the set point, set a % converted value in the range of 0 to 100%.

When both of C42 (Pr. 934) and C44 (Pr. 935) "9999".

For the set point, set PID coefficient, which corresponds with 0 to 100%.

<Measured value calibration>

1) When both or one of C42 (Pr.934) and C44 (Pr.935) is "9999".

1. Apply the input current of 0% measured value (e.g. 4mA) across terminals 4 and 5.

2. Make calibration using C6 (Pr. 904).

3. Apply the input current of 100% measured value (e.g. 20mA) across terminals 4 and 5.

4. Make calibration using C7 (Pr. 905).

2) When both of C42 (Pr.934) and C44 (Pr.935) "9999".

1. Apply the input current of 0% measured value (e.g. 4mA) across terminals 4 and 5.

2. Set PID display value at 0% measured value (example: 15(C)) to C42 (Pr. 934) , and calibrate C43 (Pr. 934).

3. Apply the input current of 100% measured value (e.g. 20mA) across terminals 4 and 5.

4. Set PID display value at 100% measured value (example: 35(C)) to C44 (Pr. 935), and calibrate C45 (Pr. 935).

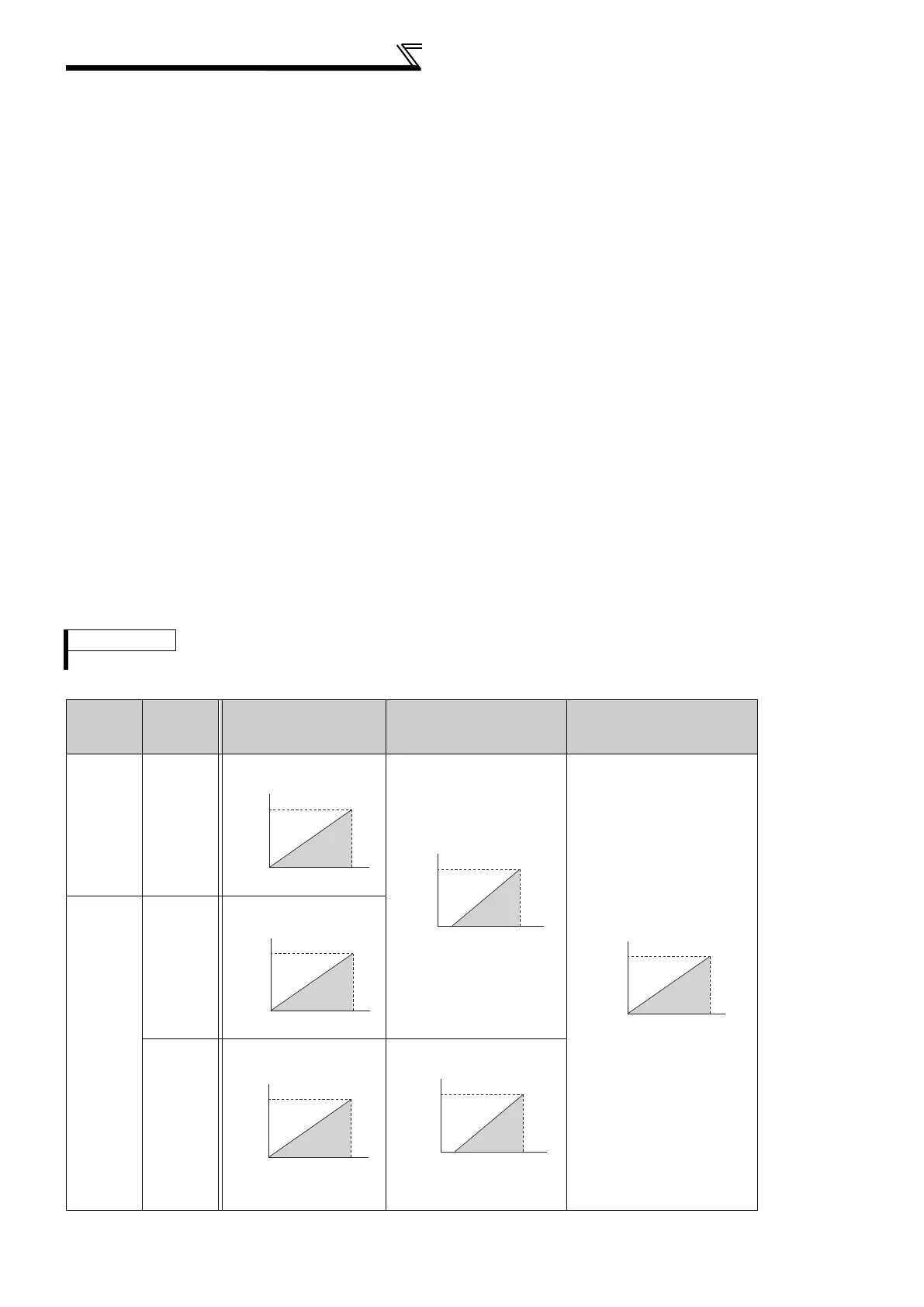

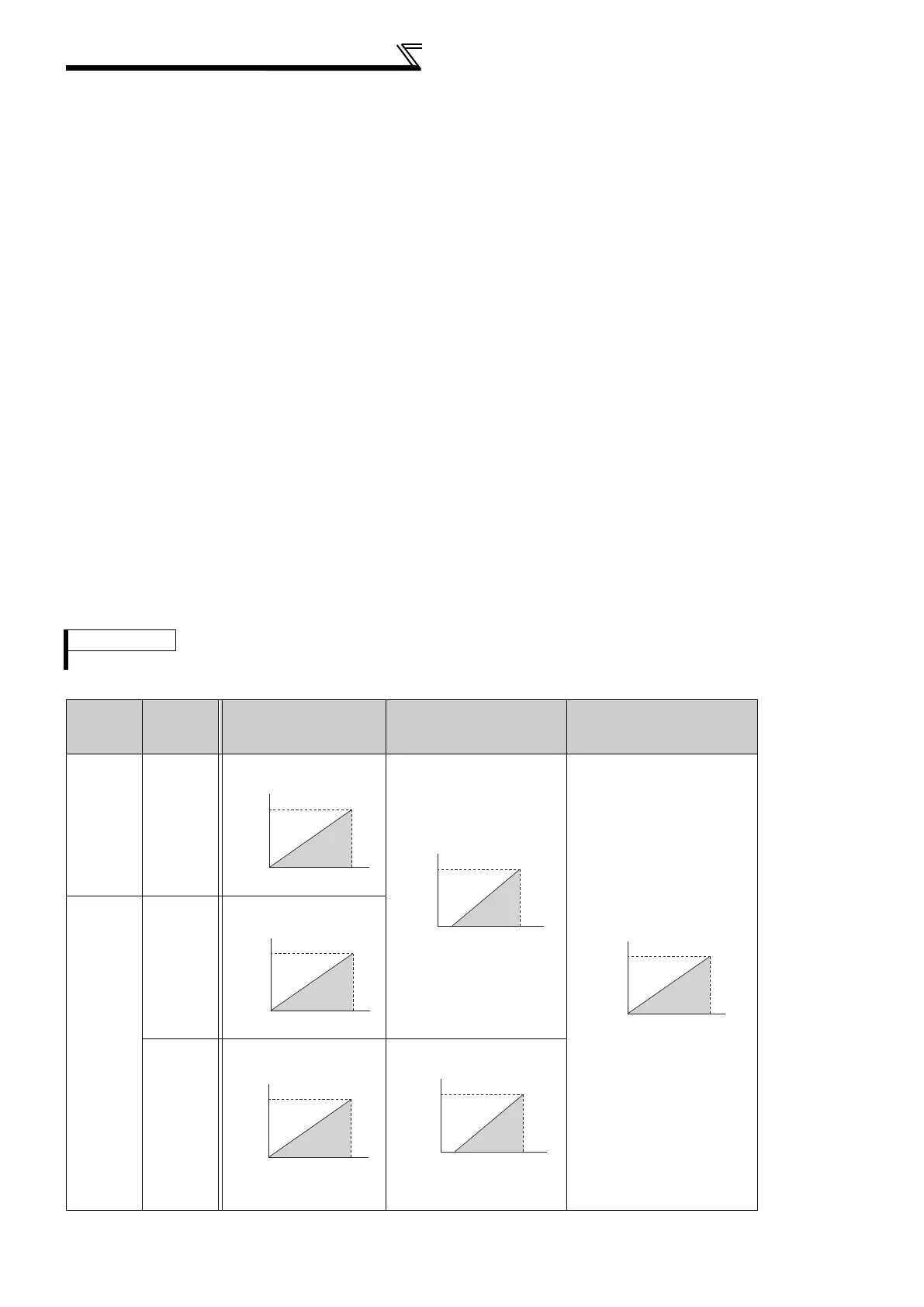

The results of the above calibration are as shown below:

REMARKS

The frequency set in C5 (Pr. 904) and Pr. 126 should be the same as set in C2 (Pr. 902) and Pr. 125.

Pr. 133

Setting

Pr. 934,

Pr. 935

Setting

Set Point Setting

Measured Value

(Terminal 4)

Manipulated Variable

9999 —

(Terminal 2)

Other than

9999

Both or one

is 9999

(Pr.133)

Other than

9999

(Pr.133)

Set PID coefficient

corresponding with 0 to 100%.

100

0

0

5 (V)

Set point signal input

Set point

(%)

100

0

0

20

C7(Pr.905)

(mA)

Measured value

input signal

Measured

Value

(%)

4

C6(Pr.904)

60

(Pr.125)

0

C2(Pr.902)

0

100

Deviation(%)

Manipulated

Variable(Hz)

100

0

C5(Pr.904)

Pr.126

Set point setting

Set point

(%)

100

0

C42(Pr.934)

C44(Pr.935)

Set point

(%)

100

0

0

20

C45(Pr.935)

(mA)

Measured value

input signal

Measured

value

(%)

4

C43(Pr.934)

Loading...

Loading...