(7) Troubleshooting

(8) Maintenance, inspection and part replacement

CAUTION

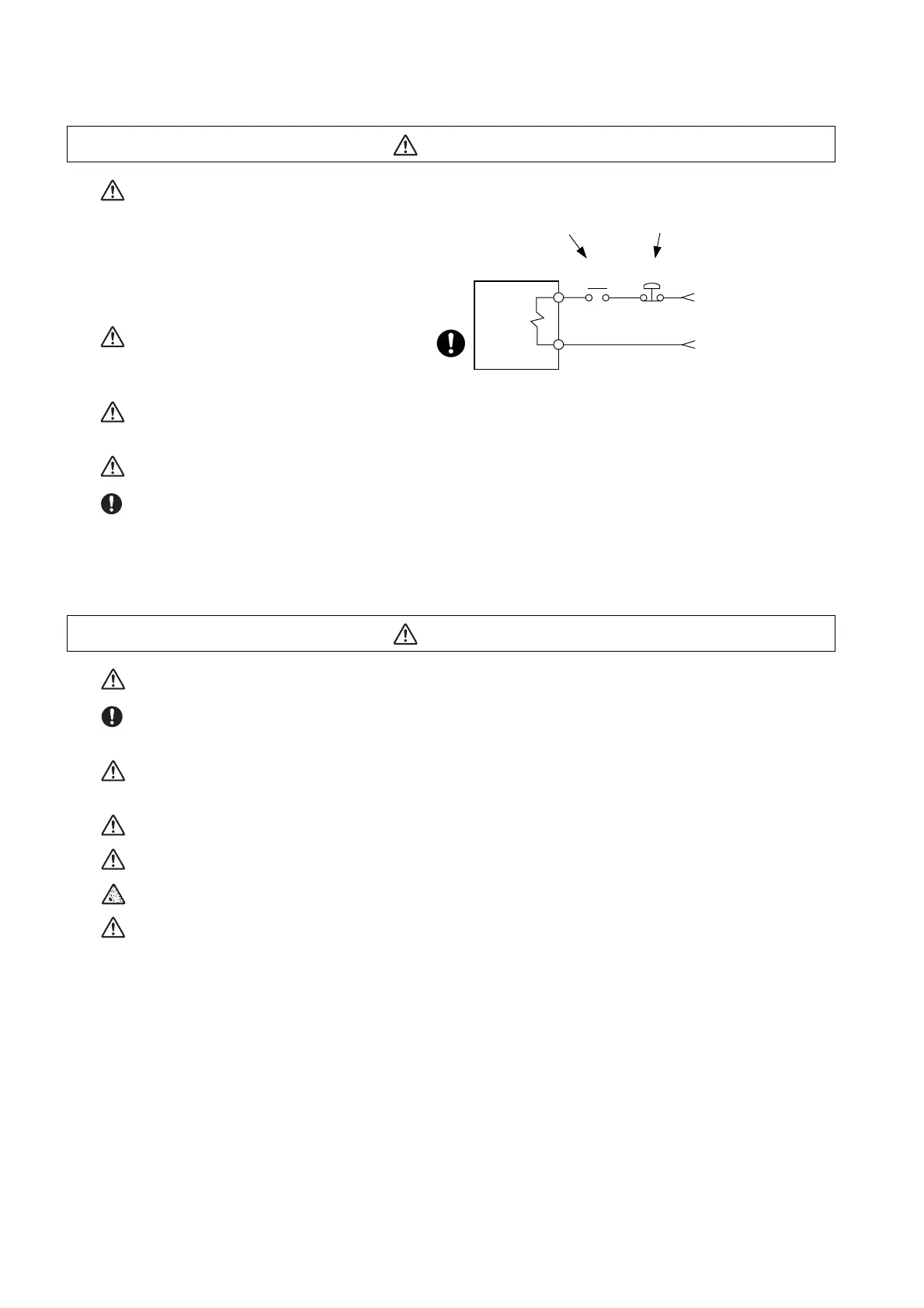

Use a motor with electromagnetic brakes or

establish an external brake mechanism for

the purpose of holding; this serves as

countermeasures for possible hazardous

situation caused by power failure or

product fault.

Use a double circuit structure for the

electromagnetic brake’s operation circuit

so that the brakes will activate even when

the external emergency stop signal is

issued.

The machine could suddenly restart when the power is restored after an instantaneous power failure, so

stay away from the machine. (Design the machine so that the operator safety can be ensured even if the

machine restarts.)

To secure the absolute position, do not shut off the servo drive unit’s control power supply when its battery

voltage drops (warning 9F) in the servo drive unit side.

If the battery voltage drop warning alarm occurs in the controller side, make sure to back up the machining

programs, tool data and parameters, etc. with the input/output device before replacing the battery.

Depending on the level of voltage drop, memory loss could have happened. In that case, reload all the data

backed up before the alarm occurrence.

CAUTION

Periodically back up the programs, tool data and parameters to avoid potential data loss. Also, back up

those data before maintenance and inspections.

When replacing the battery on the controller side, the machining programs, tool data and parameters

should be backed up with the input/output device beforehand. In case the memory is damaged in replacing

the batteries, reload all the data backed up before replacing the battery.

The electrolytic capacitor’s capacity will drop due to deterioration. To prevent secondary damage due to

capacitor’s faults, Mitsubishi recommends the electrolytic capacitor to be replaced approx. every five

years even when used in a normal environment. Contact the Service Center for replacements.

Do not perform a megger test (insulation resistance measurement) during inspection.

Do not replace parts or devices while the power is ON.

Do not short-circuit, charge, overheat, incinerate or disassemble the battery.

There may be a unit filled with substitute Freon in the heat radiating fins of the 37kW or smaller unit. Be

careful not to break the heat radiating fins during maintenance or replacement.

MBR EMG

Motor

Electro-

magnetic

brake

Shut off with motor

brake control output

Shut off with CNC brake

control PLC output

24VDC

Loading...

Loading...