6 - 57

Chapter 6 Sequence Program Used for Positioning Control

Servo ON conditions

Setting of servo parameter

PLC READY signal Y0 ON

All axis servo ON Y1 ON

Starting conditions

To start the control, the following conditions must be satisfied.

The necessary start conditions must be incorporated in the sequence program so

that the control is not started when the conditions are not satisfied.

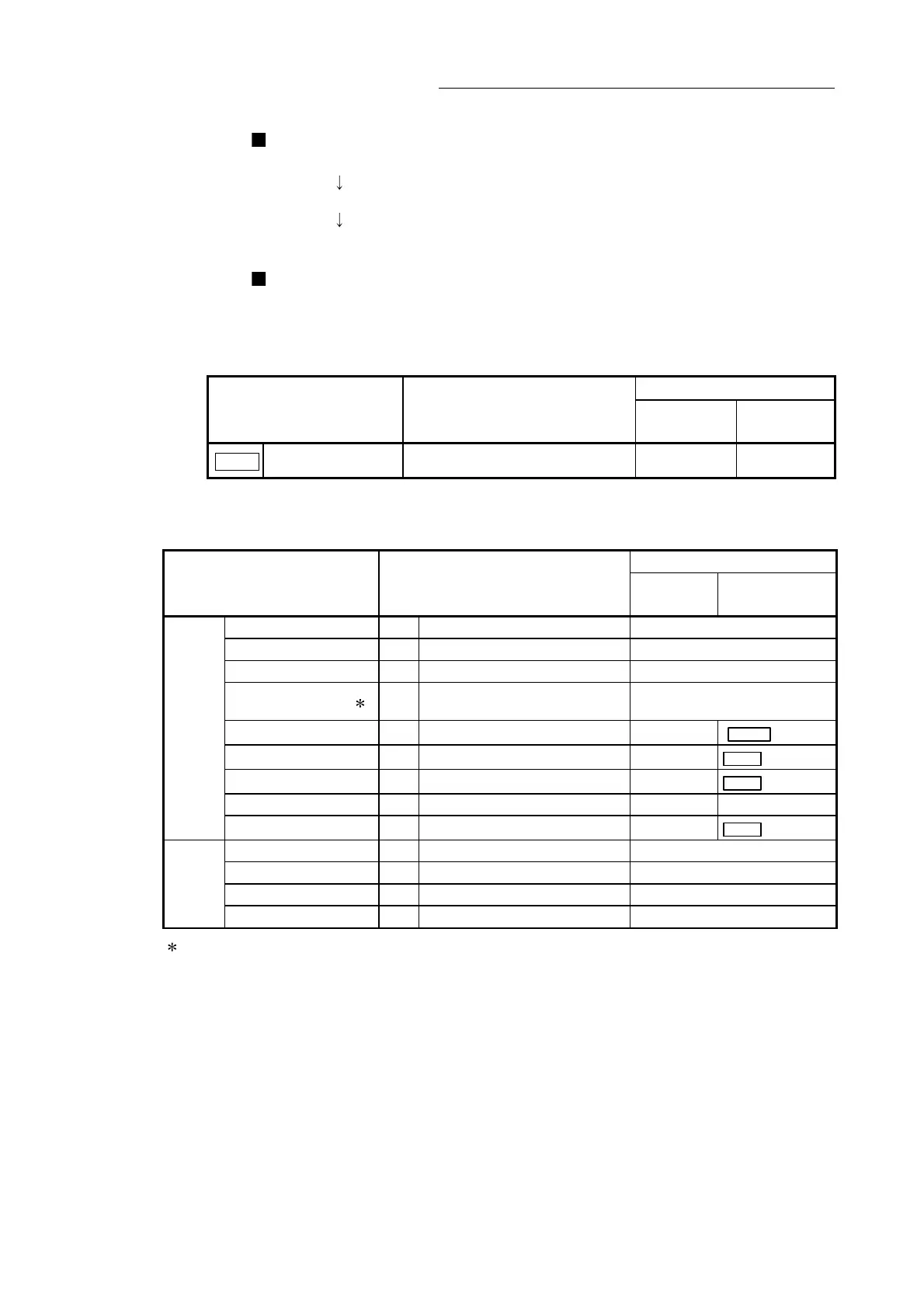

(1) Operation state

Buffer memory address

Monitor item Operation state

QD77MS2

QD77MS4

QD77MS16

Md.26

Axis operation status "0: Standby" or "1: Stopped" 809+100n 2409+100n

n: Axis No.-1

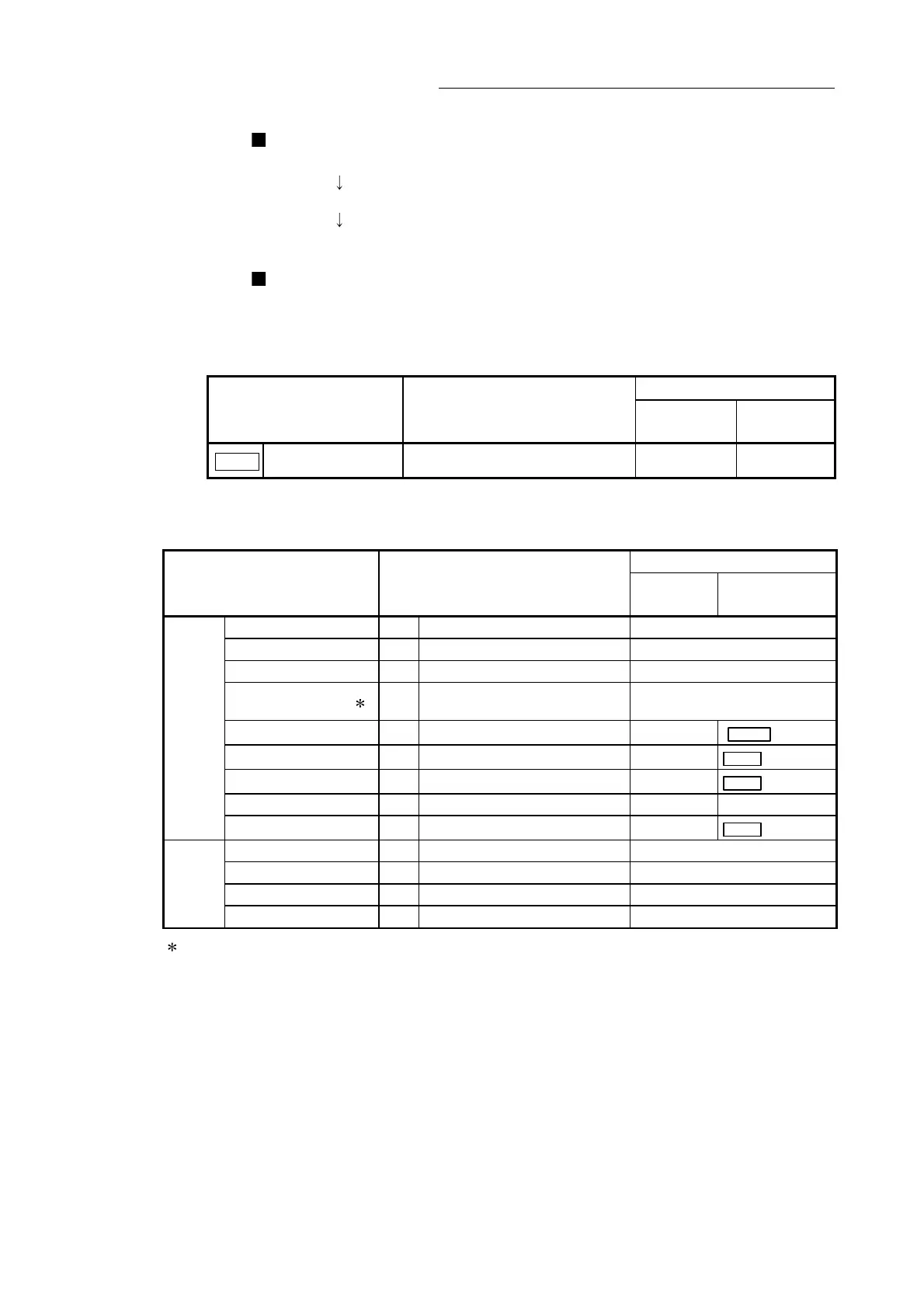

(2) Signal state

Device

Signal name Signal state

QD77MS2

QD77MS4

QD77MS16

PLC READY signal ON PLC CPU preparation completed Y0

QD77 READY signal ON QD77MS preparation completed X0

All axis servo ON ON All axis servo ON Y1

Synchronization flag ON

QD77MS buffer memory

Accessible

X1

Axis stop signal OFF Axis stop signal is OFF Y4 to Y7 Cd.180 Axis stop

M code ON signal OFF M code ON signal is OFF X4 to X7 Md.31 Status: b12

Error detection signal OFF There is no error X8 to XB Md.31 Status: b13

BUSY signal OFF BUSY signal is OFF XC to XF X10 to X1F

Interface

signal

Start complete signal OFF Start complete signal is OFF X10 to X13

Md.31 Status: b14

Forced stop input signal ON There is no forced stop input –

Stop signal OFF Stop signal is OFF –

Upper limit (FLS) ON Within limit range –

External

signal

Lower limit (RLS) ON Within limit range –

: When the synchronous setting of the PLC CPU is made in the nonsynchronous mode, this must be

provided as an interlock.

When it is made in the synchronous mode, no interlock must be provided in the program because the flag is

turned ON when calculation is run on the PLC CPU.

Loading...

Loading...