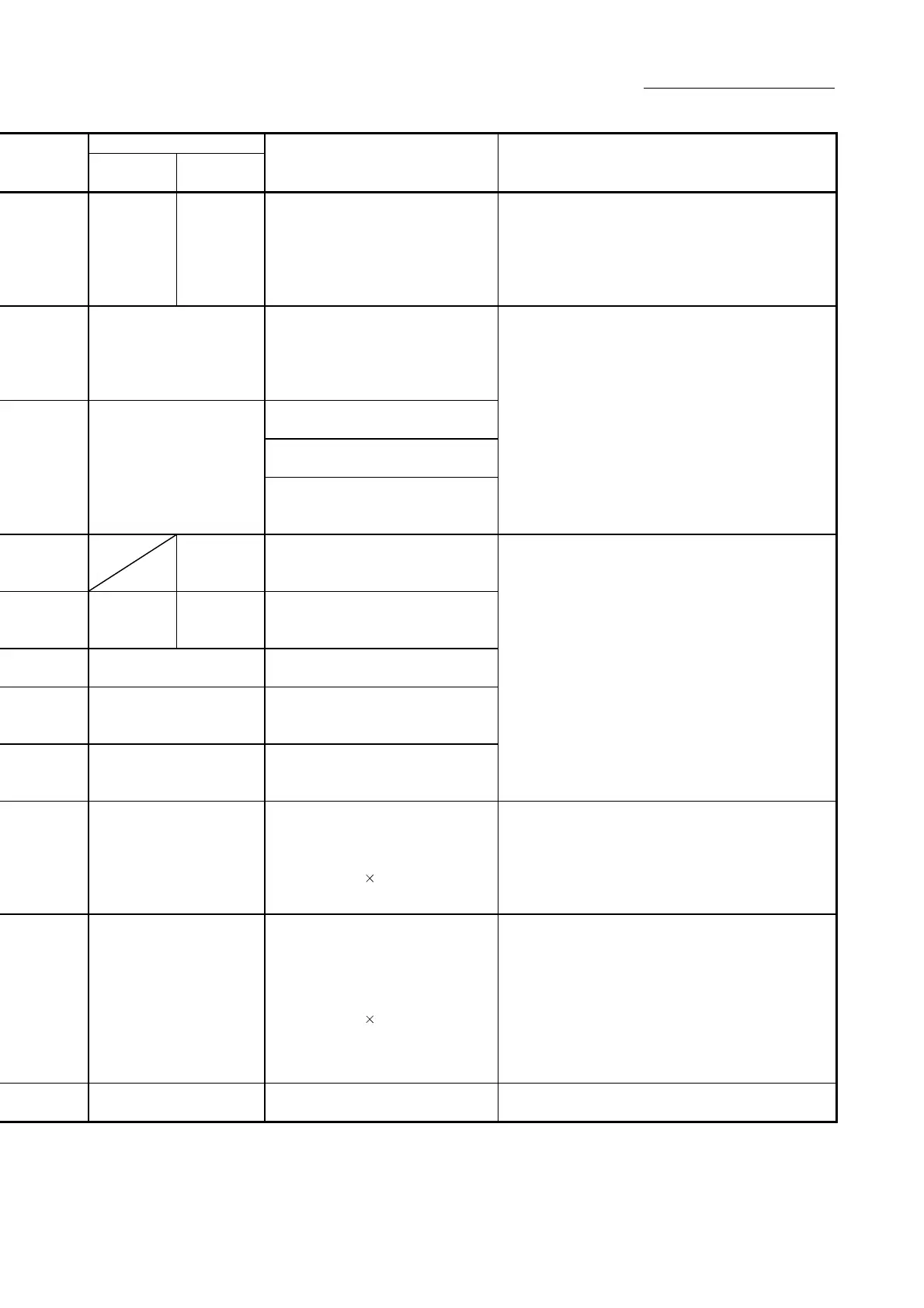

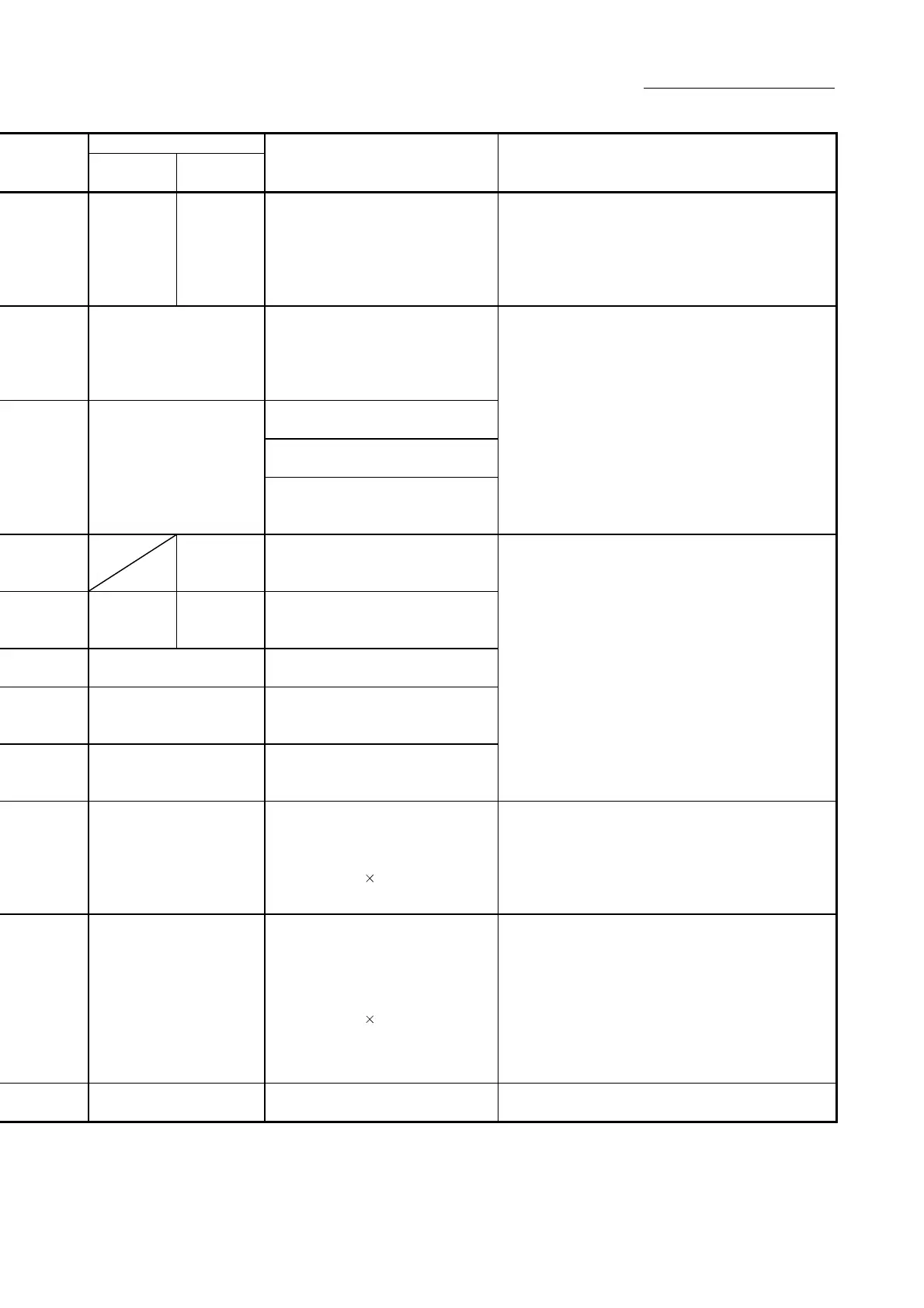

16 - 45

Chapter 16 Troubleshooting

Related buffer memory address

QD77MS2

QD77MS4

QD77MS16

Set range

(Setting with sequence program)

Remedy

— — —

• Confirm the driver communication and the actually

connected servo amplifier.

• After setting 'The driver communication setting', write to a

flash ROM and switch the power on again or reset the PLC.

After that turning the power of servo amplifier on again,

switch the power on again or reset the PLC.

67 0, 1

<Torque initial value selection (b4 to b7)>

0, 1

<Speed initial value selection (b8 to b11)>

0, 1, 2

68+150n

<Condition selection at mode switching

(b12 to b15)>

0, 1

With the setting brought into the setting range, turn the PLC

READY signal [Y0] from OFF to ON.

69+150n 0, 1, 2, 3, 4

30100+200n 28400+100n 3

70+150n 0, 1, 4, 5, 6

71+150n 0, 1

72+150n

73+150n

• [mm] [inch] [PLS]

–2147483648 to 2147483647

• [degree] 0 to 35999999

With the setting brought into the setting range, turn the PLC

READY signal [Y0] from OFF to ON.

74+150n

75+150n

<OPR speed>

1 to 1000000000 [PLS/s]

1 to 2000000000 [

10

-2

mm/min or others]

• Bring the setting into the setting range.

• Set the speed to the bias speed at start or higher.

(Refer to Section 5.2.5)

76+150n

77+150n

<Creep speed>

1 to 1000000000 [PLS/s]

1 to 2000000000 [

10

-2

mm/min or others]

• Bring the setting into the setting range.

• Set the speed to that below the OPR speed.

• Set the value to the bias speed at start or higher.

(Refer to Section 5.2.5)

78+150n 0, 1

With the setting brought into the setting range, turn the PLC

READY signal [Y0] from OFF to ON.

Loading...

Loading...