10-88

Printing the Label Job

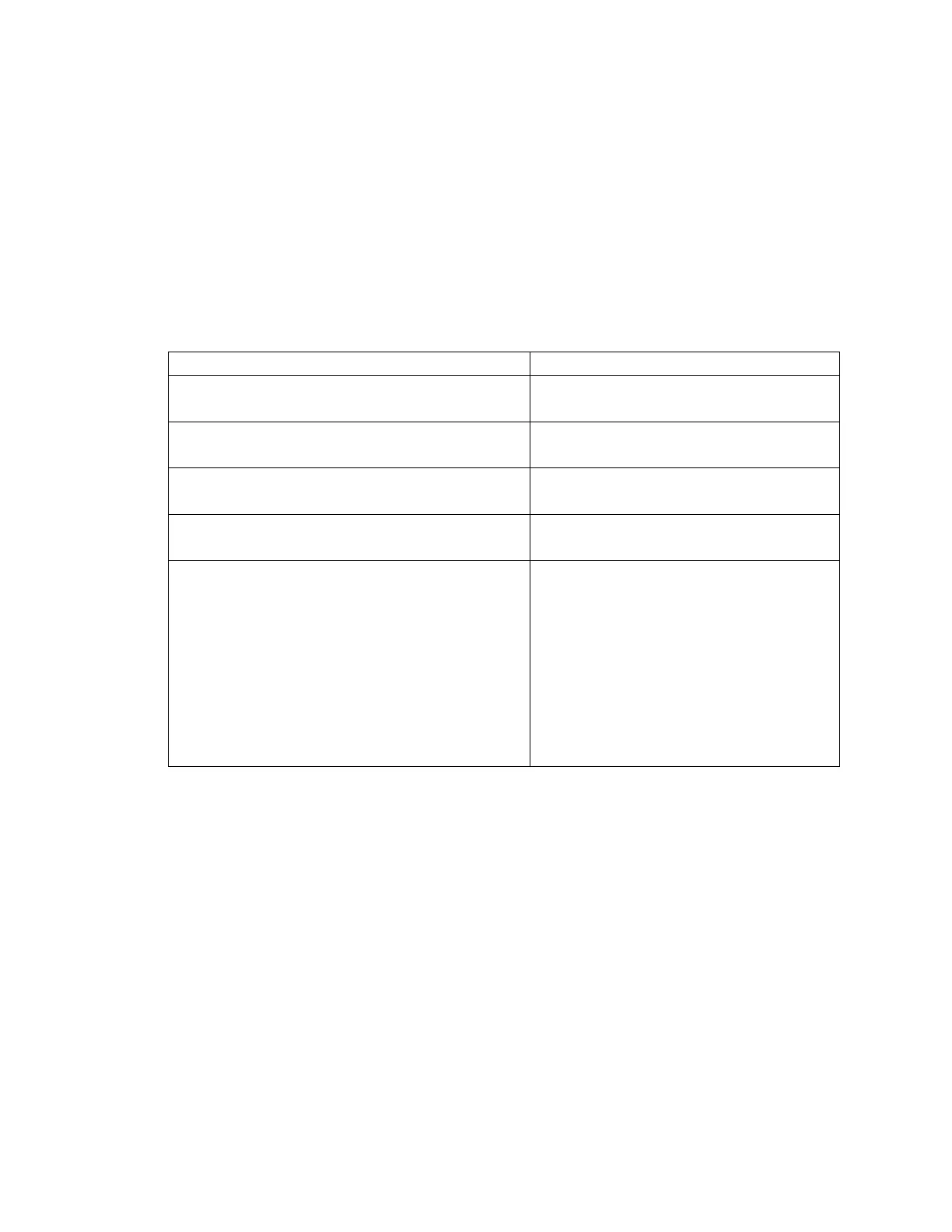

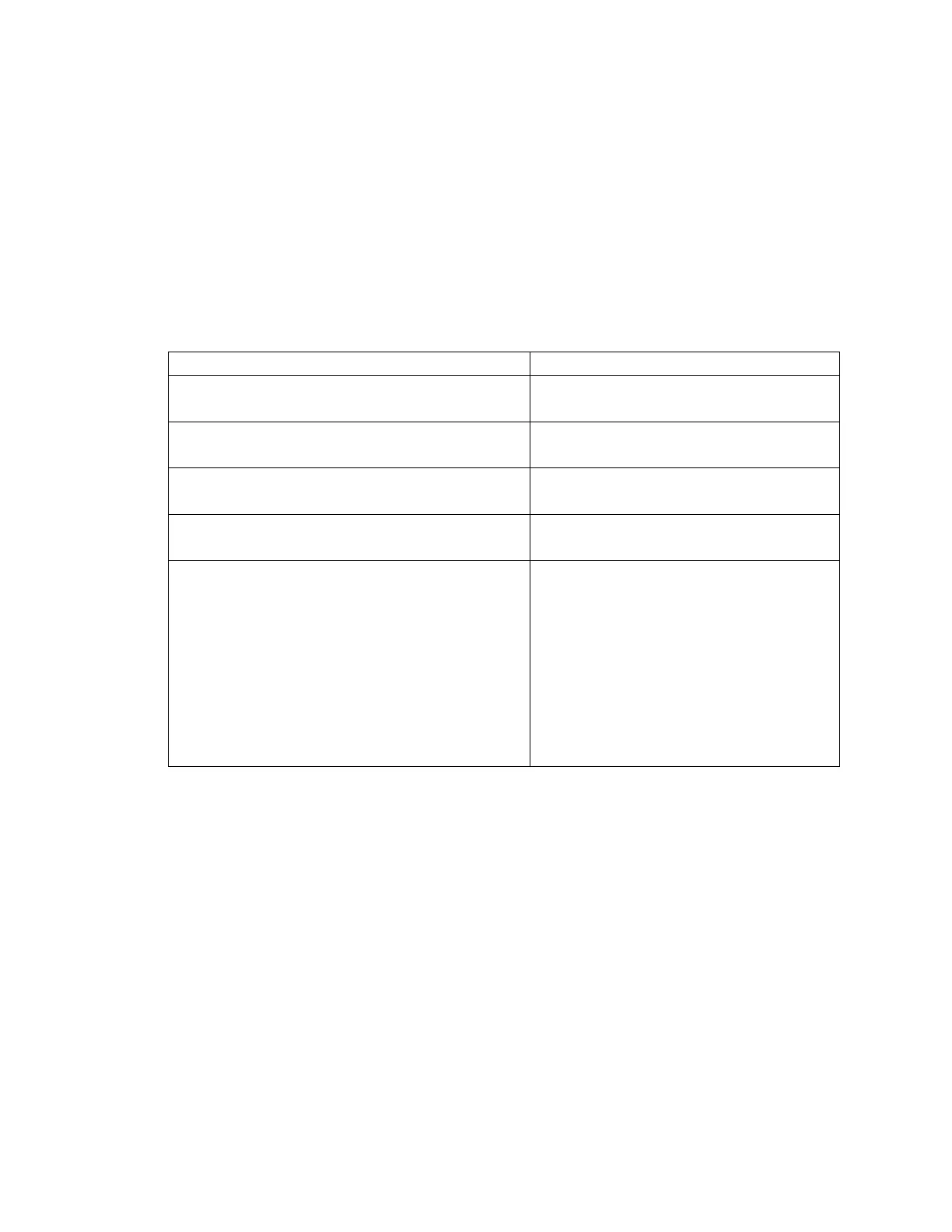

Once you are satisfied with the layout and quality of the sample print, you are ready to print

the label batch. Print a small batch of 10-20 labels. Verify that all labels have printed

successfully. The table provides a summary of issues you might see and suggested adjustment

for each of those issues.

Printhead Height

Set to a higher level

Lower Intensity

Slow Speed

Printer Stops in middle of print with jagged

edges on sequenced print

Printer can’t keep up.

Lower speed or quality

Printer feeds blank media

Mark is selected for gapped media

Gap is selected for marked media

Printer skips blank page in between labels

- Create smaller page size, or

- Use Full Bleed Overspray with a

negative value.

Black mark is not seen by sensor.

- Make sure the mark adheres to

color & placement specifications.

- Try adjusting sensor brightness.

- Try switching to using gaps.

Table: Adjustments in Printing a Label Batch

Printing Workflows

The following sections explain how to use the printer in basic workflow scenarios such as

canceling a job, clearing a media job, changing ink and continuing a job when media runs out.

Canceling a Job

There are several ways to cancel the currently printing job. Jobs that are actively printing

should stop printing as soon as cancel has been selected. However in some cases jobs that are

Loading...

Loading...