42615101TH Rev.8 30 /

Oki Data CONFIDENTIAL

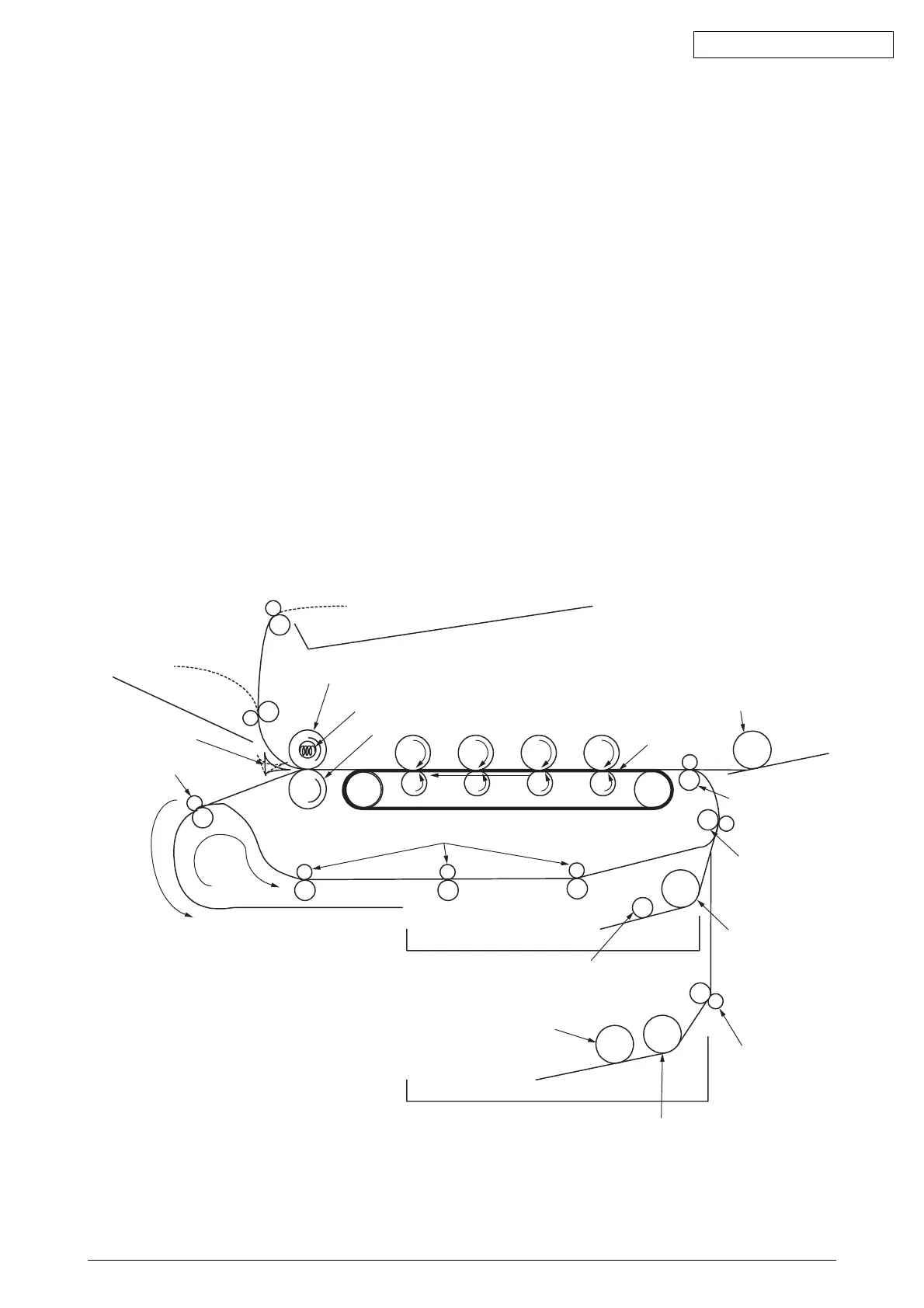

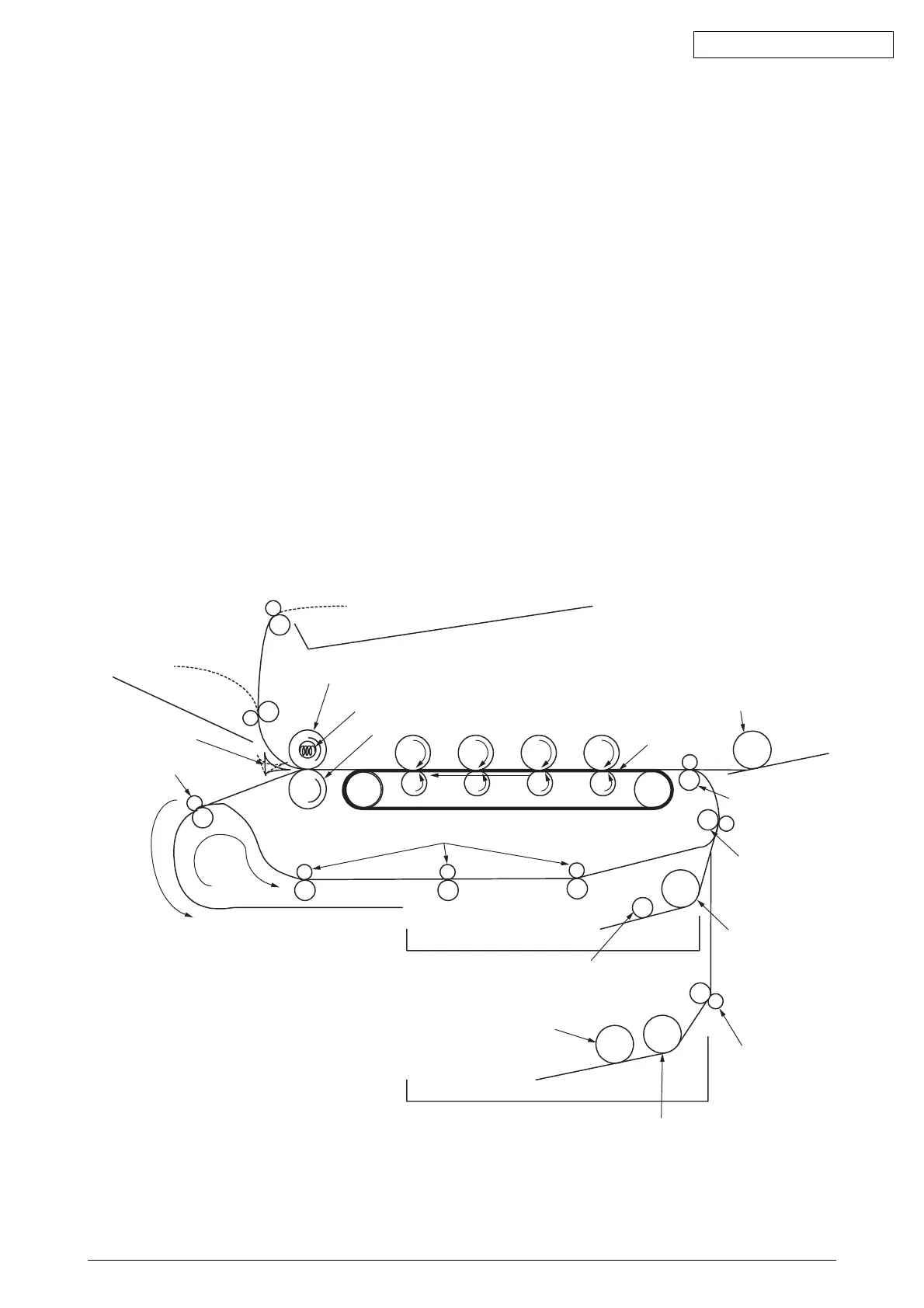

2.2 Printing Processes

Paper fed from a tray 1 or 2 is forwarded by Hopping roller, Registration Roller L and Feed roller.

When feeding paper from a multiple tray, it is forwarded by a MPT Hopping roller and Registration

Roller U. Then, the paper is moved onto a transfer belt and, through K, Y, M and C electrophotographic

processes performed taking their turns, a yet-to-be-fused toner image is produced on the paper.

While the paper passes through a fuser unit, heat and pressure fuses the toner to the paper. After

the fusing process, the paper is ejected to a face-up or face-down stacker, whichever is selected

according to whether the face-up stacker is opened.

These operations are performed in single-side printing. Following are operations in two-side

(duplex) printing.

In duplex printing, paper passed through a fuser unit after it is first printed on the back is fed into

a duplex unit via a dup-in separator. Reversing roller’s reversing operation sends the paper via a

paper reversing path into the duplex unit. After Feed rollers on a paper path in the duplex unit pass

the paper through the unit, the paper is fed via a paper feeding path routed from the unit. Then,

the paper is forwarded to the same route from the tray. After that, the same operation as that

performed after the paper moving by the first registration roller L in single-side printing using tray

feeding is performed.

MPT

Reversing Roller

Dup-In Separator

Face-up Stacker

Face-down Stacker

Heat Roller

Halogen Lamp

Backup Roller

Transfer Belt

Registration Roller U

Registration Roller L

MPT Hopping Roller

Feed Roller

Sub Roller

Sub Roller

Hopping Roller

Hopping Roller

Feed Rollers

Paper Reversing Path

Loading...

Loading...