42615101TH Rev.8 162 /

Oki Data CONFIDENTIAL

5.5 Settings after Parts Replacement

Adjustments required after parts replacement are described below.

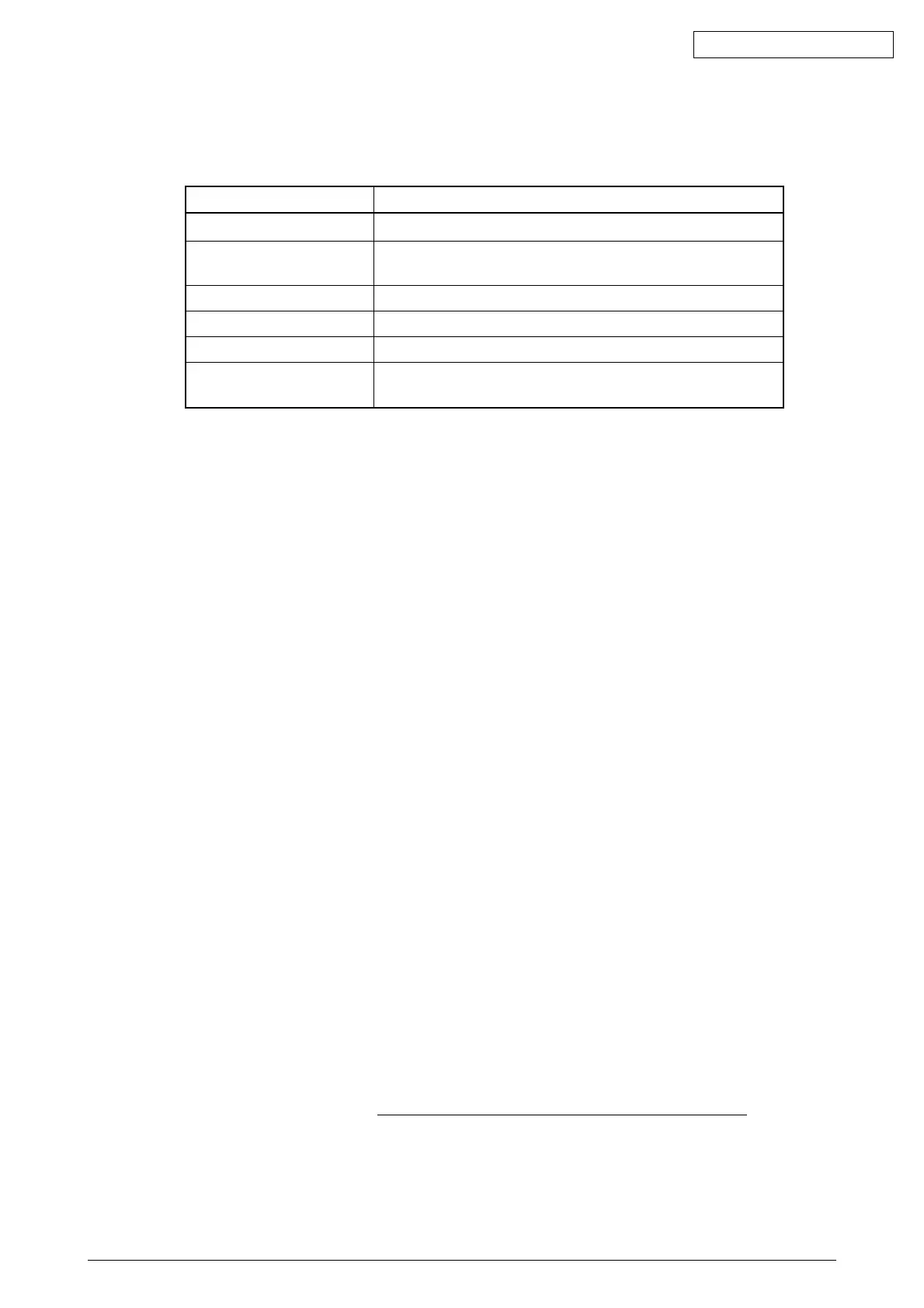

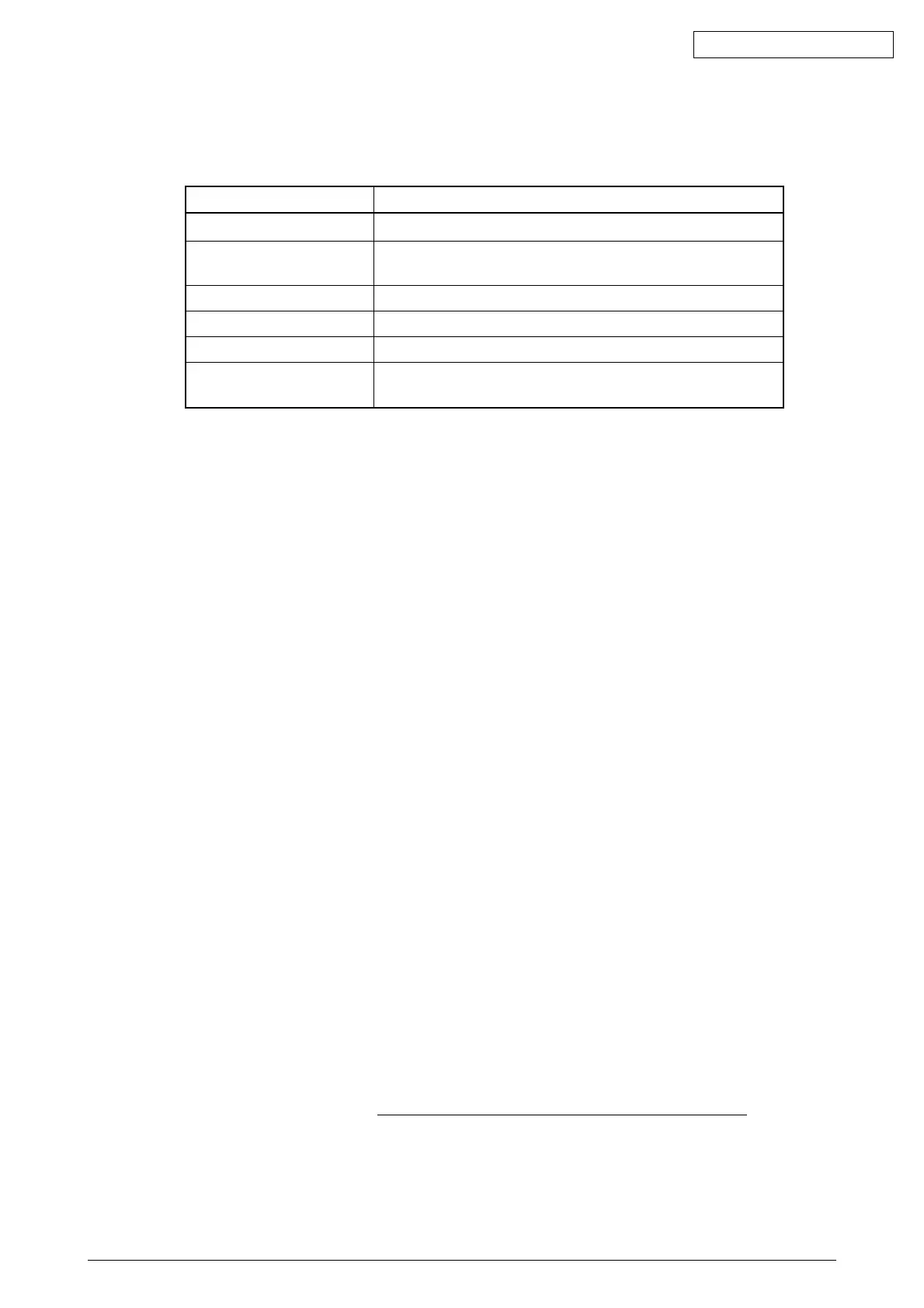

Replaced Part Adjustment

LED Head Not required.

Image Drum Cartridge Not required.

(Any of Y, M, C and K)

Fuser Unit Not required.

Belt Unit Not required.

PU (PRN Board) Copying of EEPROM data and Utility

CU (ARC Board / SPY Board Copying of EEPROM data and Utility

/ SPA Board)

5.5.1 Instructions to exchange the engine control board

1. EEPROM of the board to be removed is accessible [SERVICE CALL 105 (ENGINE EEPROM

Error) is not shown]

(1) Take EEPROM information from a board to be removed by PU board exchange function of

the maintenance utility (Operation manual of the maintenance utility 2.4.1.1, and 2.4.1.2 PU

board exchange function) to store in HDD of the computer temporarily.

(2) Copy EEPROM information stored in HDD of the computer as shown in (1) with PU board

exchange of the maintenance utility (Operation manual of the maintenance utility 2.4.1.1,

and 2.4.1.2 PU board exchange function) to a EEPROM of the board to be installed newly.

Note!

When taking or writing EEPROM information in the maintenance utility, set a printer to

“Forced ONLINE Mode” in the following order before accessing to EEPROM. In addition,

an error message is shown in Forced ONLINE Mode when the printer is in an error.

1)Press [BACK]+[MENU-]+[ENTER] until “STATUS MODE” is displayed in the operator

panel when turning on the printer.

2) After that, “ONLINE” is displayed when the device status is normal, but an error message

is displayed when the device has an error. Meantime, inside of the device is an ONLINE

state and it is communicable.

2. EEPROM of the board to be removed is not accessible

Operate with the maintenance utility in the following order after exchanging to a new board if

SERVICE CALL 105 (Engine EEPROM Error) is displayed in the operator panel for the board

to be removed or EEPROM data cannot be read.

(1) The setting of the PU serial number

(Operation manual of the maintenance utility 2.4.1.2 PU board Setting)

The SAP serial number is applied to the device. The SAP serial number, which is the total

12 digits consisted of two digits for a manufacturing base, two digits for a date of manufacture,

six digits for a manufacture number (Sequence No.) and two digits for a revision number, is

shown in the top of the serial number label.

• The PU serial number is

10- digit number without 2 digits for a revision number of SAP

serial number 12 digits.

• Set in the “2.4.1.1.2 PU serial number setting” screen of “2.4.1.1.2.1 PU board setting”

of the maintenance utility.

Loading...

Loading...