7 Inspection and Maintenance

7-2

CJ2 CPU Unit Hardware User’s Manual

7-1 Inspections

Daily or periodic inspections are required in order to maintain the PLC's functions in peak operating

condition.

Although the major components in CJ-series PLCs have an extremely long life time, they can deterio-

rate under improper environmental conditions. Periodic inspections are thus required to ensure that the

required conditions are being kept.

Inspection is recommended at least once every six months to a year, but more frequent inspections will

be necessary in adverse environments.

Take immediate steps to correct the situation if any of the conditions in the following table are not met.

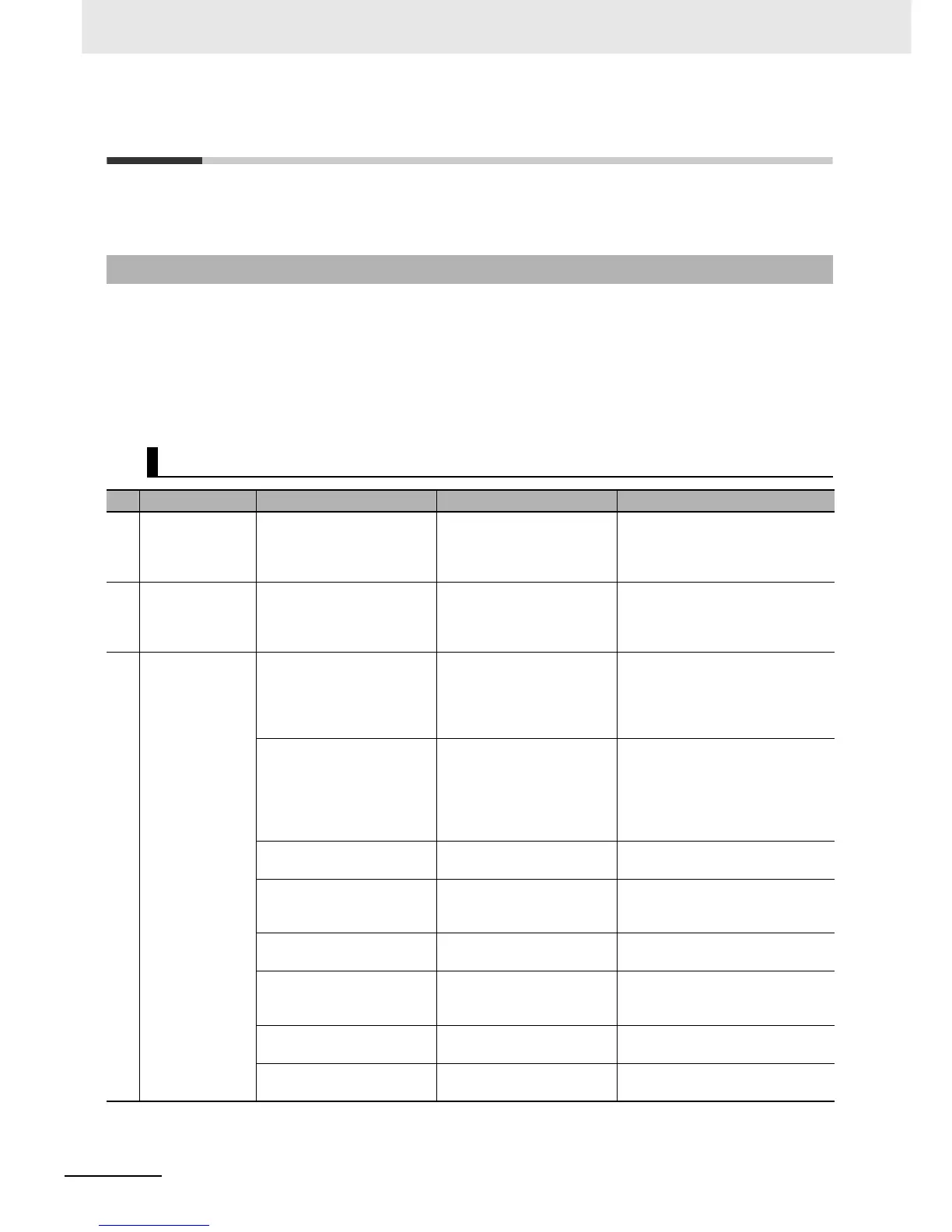

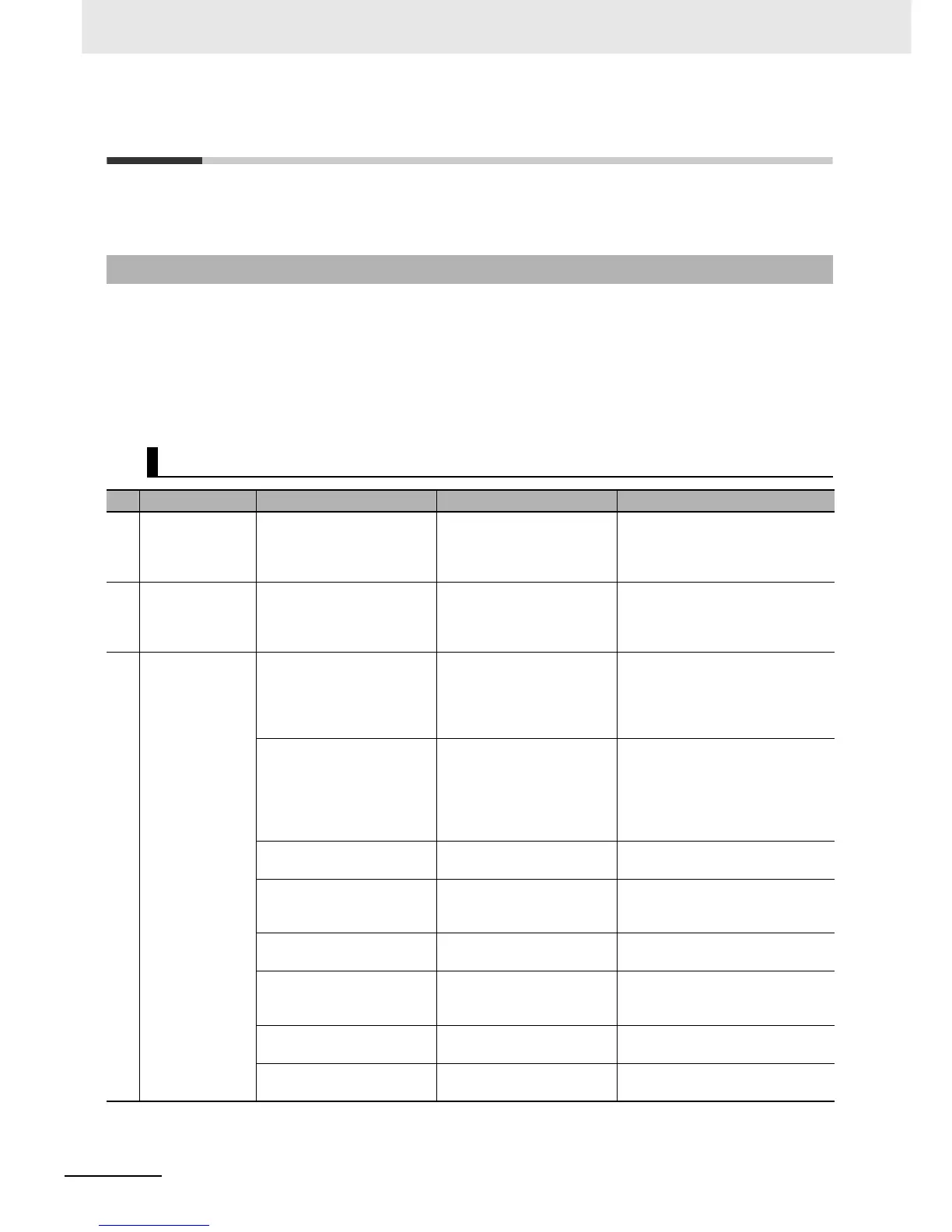

7-1-1 Inspection Points

Periodic Inspection Points

No. Item Inspection Criteria Action

1 Source Power

Supply

Check for voltage fluctua-

tions at the power supply ter-

minals.

The voltage must be within

the allowable voltage fluctua-

tion range.

Use a voltage tester to check the

power supply at the terminals. Take

necessary steps to bring voltage

fluctuations within limits.

2 I/O Power Supply Check for voltage fluctua-

tions at the I/O terminals.

Voltages must be within

specifications for each Unit.

Use a voltage tester to check the

power supply at the terminals. Take

necessary steps to bring voltage

fluctuations within limits.

3 Ambient environ-

ment

Check the ambient tempera-

ture. (Inside the control panel

if the PLC is in a control

panel.)

0 to 55°C Use a thermometer to check the

temperature and ensure that the

ambient temperature remains

within the allowed range of 0 to

55°C.

Check the ambient humidity.

(Inside the control panel if

the PLC is in a control

panel.)

Relative humidity must be

10% to 90% with no conden-

sation.

Use a hygrometer to check the

humidity and ensure that the ambi-

ent humidity remains between 10%

and 90%. Make sure that conden-

sation does not occur due to rapid

changes in temperature.

Check that the PLC is not in

direct sunlight.

Not in direct sunlight Protect the PLC if necessary.

Check for accumulation of

dirt, dust, salt, metal filings,

etc.

No accumulation Clean and protect the PLC if nec-

essary.

Check for water, oil, or chem-

ical sprays hitting the PLC.

No spray on the PLC Clean and protect the PLC if nec-

essary.

Check for corrosive or flam-

mable gases in the area of

the PLC.

No corrosive or flammable

gases

Check by smell or use a sensor.

Check the level of vibration

or shock.

Vibration and shock must be

within specifications.

Install cushioning or shock absorb-

ing equipment if necessary.

Check for noise sources near

the PLC.

No significant noise sources Either separate the PLC and noise

source or protect the PLC.

Loading...

Loading...