4 System Design

4 - 4

OMNUC G5-series (Pulse-train Input Type) AC Servomotors and Servo Drives User’s Manual

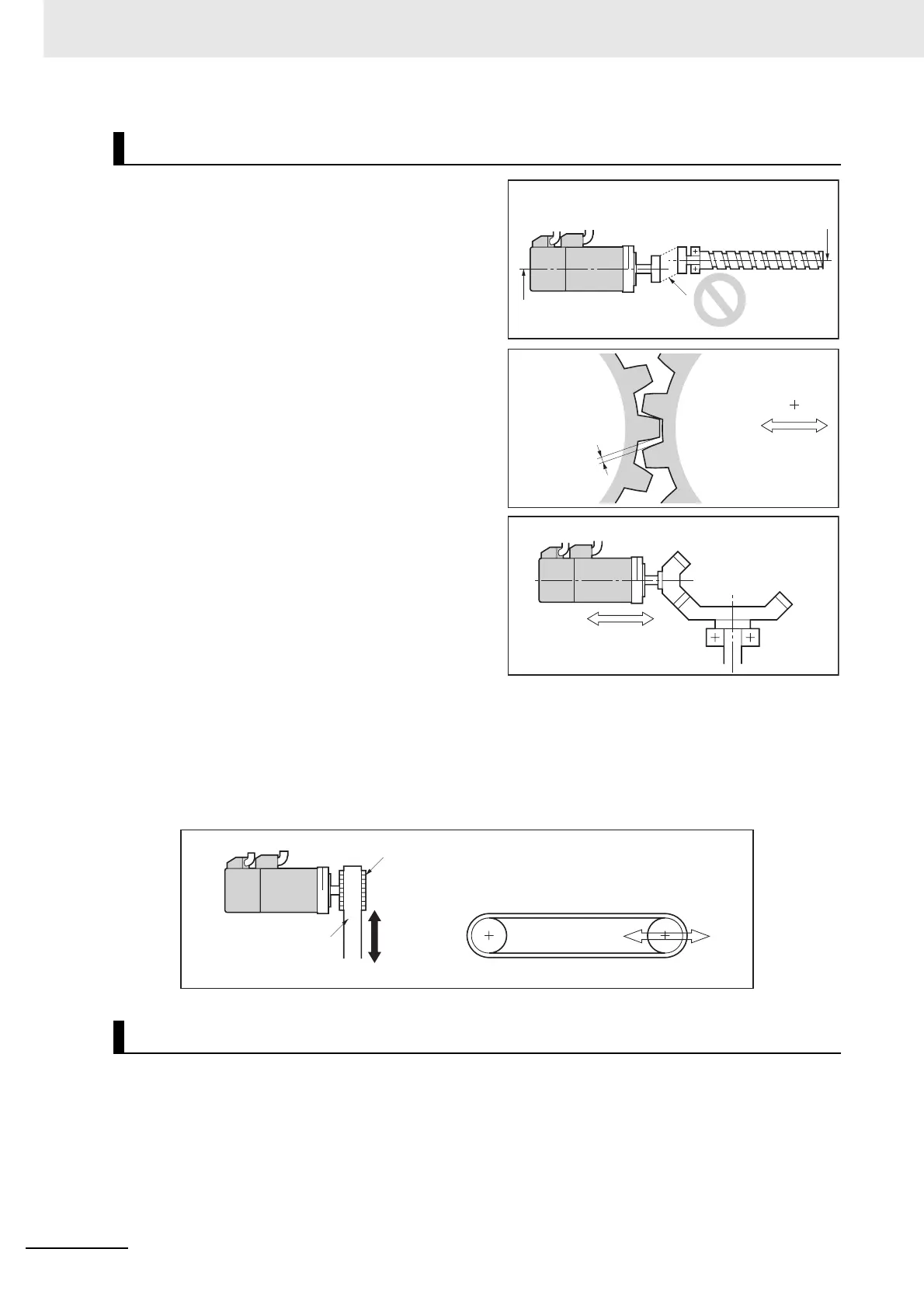

• For the allowable axial loads for motors, refer to

3-1-2 Characteristics on page 3-3. If an axial load

greater than that specified is applied to a motor, it

may reduce the limit of the motor bearings and

may break the motor shaft.

• When connecting to a load, use couplings that can

sufficiently absorb mechanical eccentricity and

declination.

• For spur gears, an extremely large radial load may

be applied depending on the gear precision. Use

spur gears with a high degree of precision (for

example, JIS class 2: normal line pitch error of

6 µm max. for a pitch circle diameter of 50 mm).

• If the gear precision is not adequate, allow

backlash to ensure that no radial load is placed on

the motor shaft.

• When using bevel gears, a load is applied in the

thrust direction depending on the structural

precision, the gear precision, and temperature

changes. Provide appropriate backlash or take

other measures to ensure that a thrust load larger

than the specified level is not applied.

• Do not put rubber packing on the flange surface. If

the flange is mounted with rubber packing, the

motor flange may crack under the tightening force.

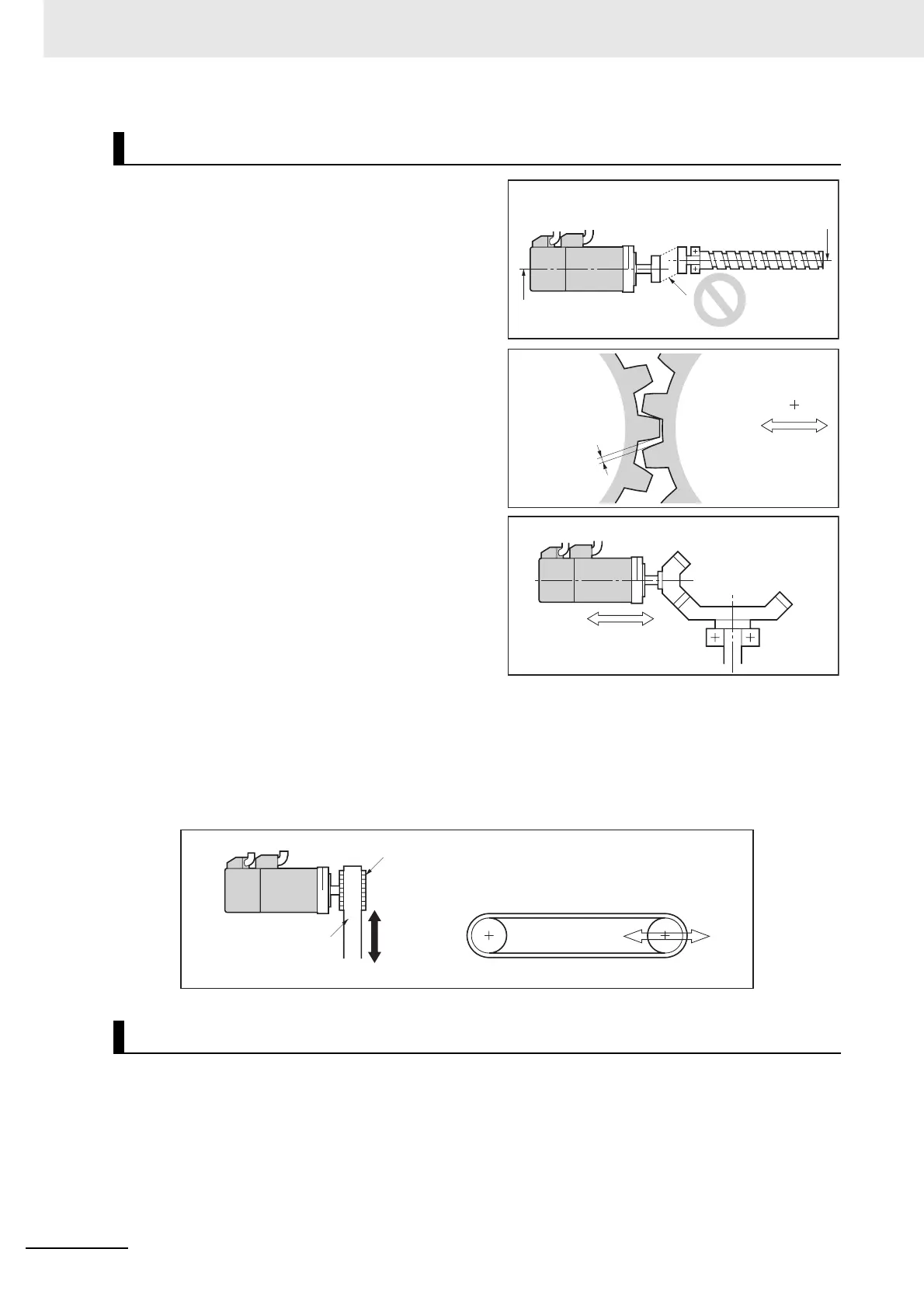

• When connecting to a V-belt or timing belt, consult

the manufacturer for belt selection and tension.

• A radial load twice as large as the belt tension will be placed on the motor shaft. Do not allow a load

that exceeds the allowable radial load to be placed on the motor shaft. If an excessive radial load is

applied, the motor shaft and bearings may be damaged.

• Set up a movable pulley in the middle of the motor shaft and the load shaft so that the belt tension

can be adjusted.

• The protective structure for the motors is as follows:

Equivalent to IP65 (except for through-shaft parts)

Connecting to Mechanical Systems

Water and Drip Resistance

Set a movable

structure.

Bevel gear

Set a structure in

which the distance

between axes can

be adjusted.

Backlash

Motor center line

Ball screw center line

Axial offset

Axial offset

Pulley

Belt

Tension

Tension adjustment

(Set a movable structure.)

Loading...

Loading...