7 Parameter Details

7 - 54

OMNUC G5-series (Pulse-train Input Type) AC Servomotors and Servo Drives User’s Manual

• For details about the display, refer to 8-4 Mode Setting on page 8-6.

• Do not set.

• Set the maximum command pulse input value. A Command Pulse Frequency Error (Alarm No. 27.0)

occurs if the command pulse input frequency exceeds this value x 1.2.

• The Servo Drive detects the Command Pulse Frequency Error for pulses it has accepted. Therefore,

if may not detect the error if the number of input pulses is much larger than the value set in this

parameter. In addition, setting the value to 1,000 or less enables the use of the digital filter for the

command pulse input as shown in the table below.

Explanation of Set Values

• Set whether to enable or disable the detection of the Pulse Regeneration Error (Alarm No. 28.0).

Explanation of Set Values

• Set whether or not to restrict operations on the front panel.

• The restricted operation varies depending on the mode as shown in the table below.

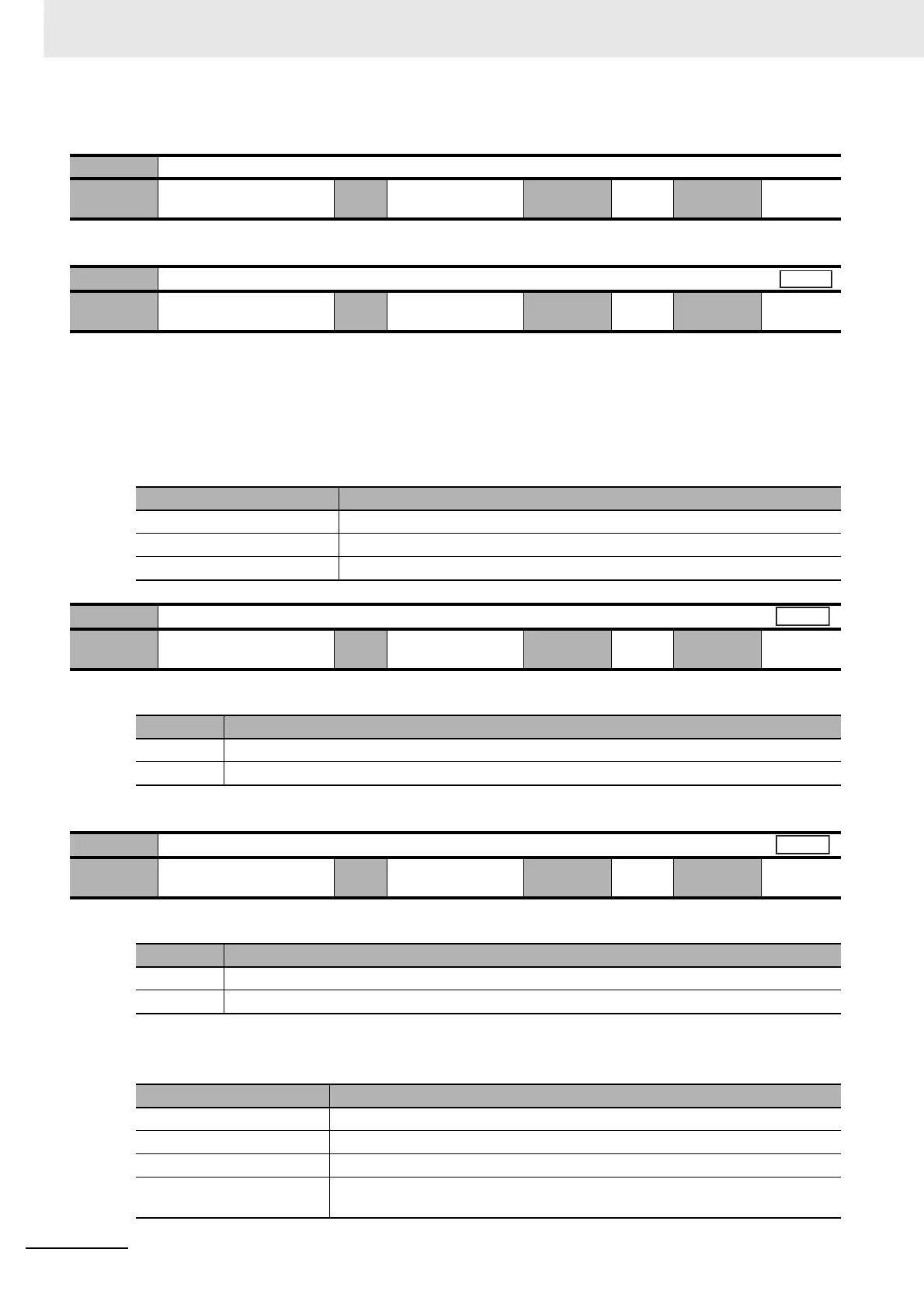

Pn531 Reserved

Setting

range

1 Unit – Default

setting

1

Cycle the

power supply

–

Pn532

Command Pulse Input Maximum Setting

Setting

range

250 to 4,000 Unit Kpps Default

setting

4,000

Cycle the

power supply

Required

Pn532 set value Digital filter

250 to 499 200 ns × 2 readings

500 to 999 100 ns × 2 readings

1,000 to 4,000 None (through)

Pn533

Pulse Regeneration Output Limit Setting

Setting

range

0 to 1 Unit – Default

setting

0

Cycle the

power supply

Required

Set value Description

0 Error detection disabled

1 Error detection enabled

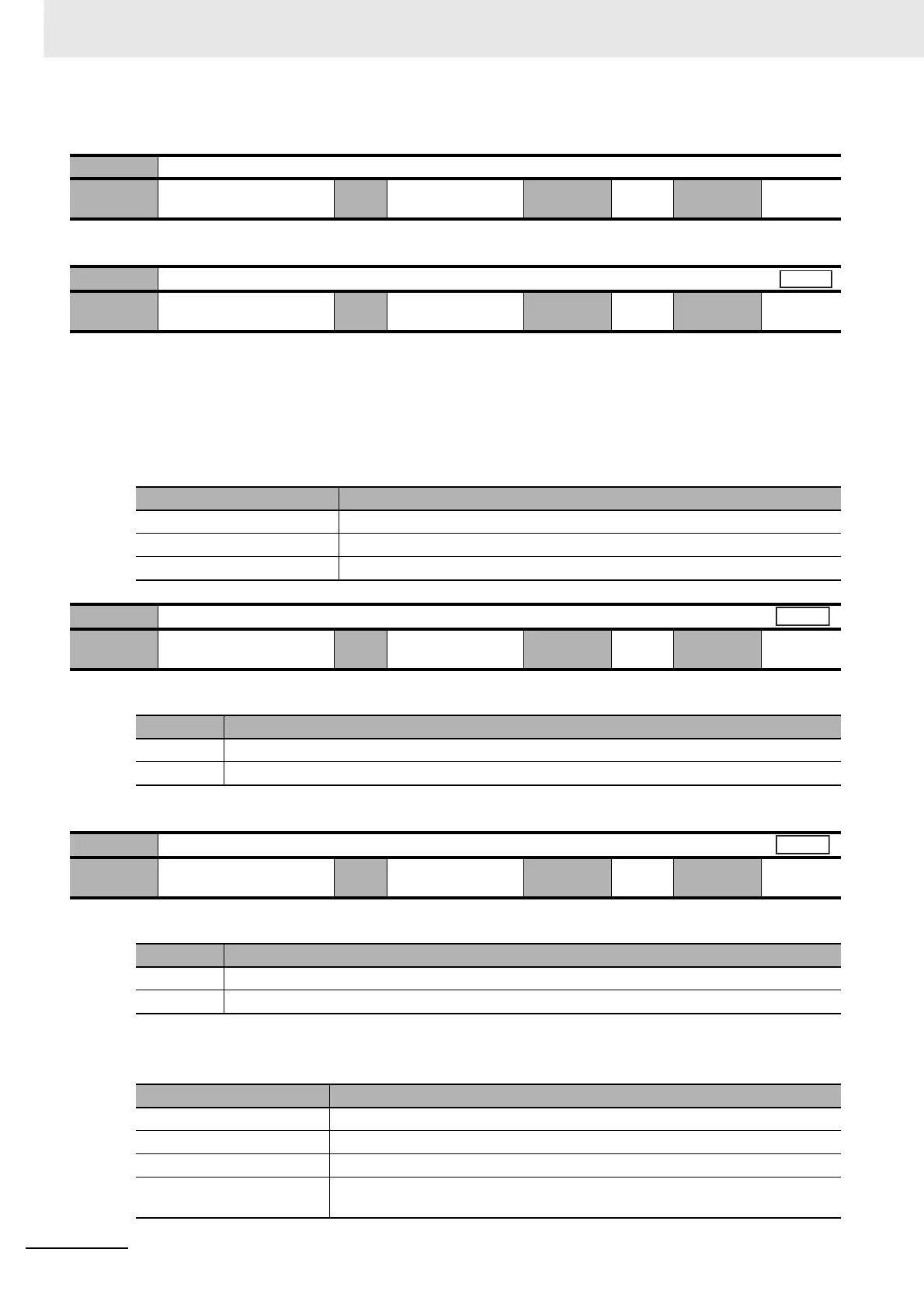

Pn535

Front Key Protection Setting

Setting

range

0 to 1 Unit – Default

setting

0

Cycle the

power supply

Required

Set value Description

0 Front panel operation not restricted

1 Front panel operation restricted

Mode Operations restricted

Monitor Mode All monitor data can be viewed.

Parameter Setting Mode Parameters cannot be changed. However, set parameter values can be viewed.

EEPROM Write Mode Unavailable (Not displayed)

Ancillary Function Mode Operations other than disabling the front key protection setting are unavailable

(not displayed).

Position

All

All

Loading...

Loading...