VR2 CONTROL SYSTEM

SK77898/2

PG DRIVES TECHNOLOGY

32

These recommendations are derived from well proven field experience of various

international wheelchair manufacturers. Nevertheless, manufacturers must confirm

these recommendations by carrying out suitable tests. Keep wire lengths as short as

possible.

Battery , motor and on-board charger wires should use Tri-

rated PVC equipment wire rated at 105°C.

5.3 Battery Wiring

The control system incorporates sophisticated current limiting circuitry as protection

for the circuits in the control system.

ISO 7176-14 requires you to provide protection against short circuits in the battery

wiring and the power loom or the extremely unlikely event of a short circuit in the

control system.

Place a suitable circuit breaker in series with the battery supply (refer to sections 3.1

+ 3.2), for example in the link between two 12V batteries. If your batteries are held in

separate enclosures, you must provide a circuit breaker with each of them.

The rating of the circuit breaker must match the capacity of the wiring used. We

recommend the use of a 70A circuit breaker. This recommendation is derived from

well proven field experience of various international wheelchair manufacturers.

Nevertheless, manufacturers must confirm these recommendations by carrying out

suitable tests.

ISO 7176-14 states that the minimum operating time for the circuit breaker when the

wheelchair is stalled is 15 seconds.

The chair manufacturer must install a suitable circuit breaker

to provide protection against short circuits in the battery

wiring, power loom or the control system. Failure to comply

with this could result in a fire hazard. PGDT accepts no

liability for losses of any kind arising from failure to comply

with this condition.

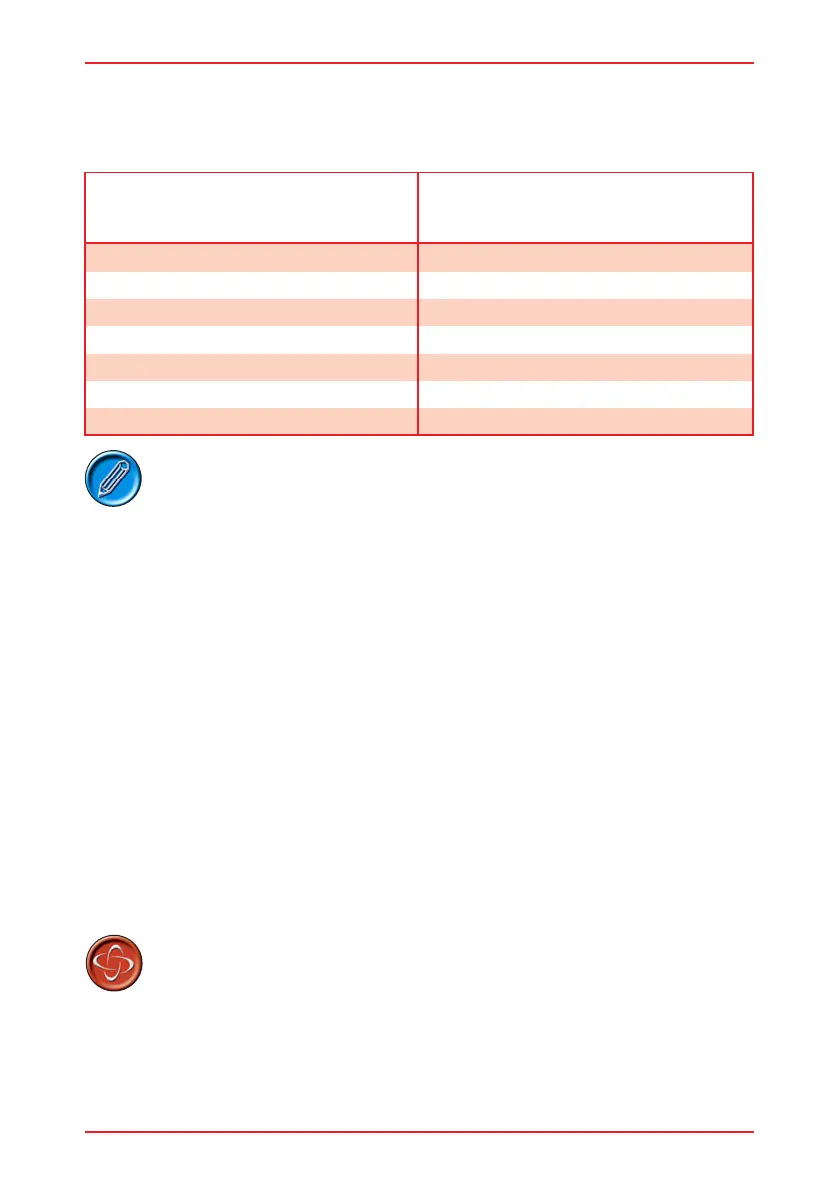

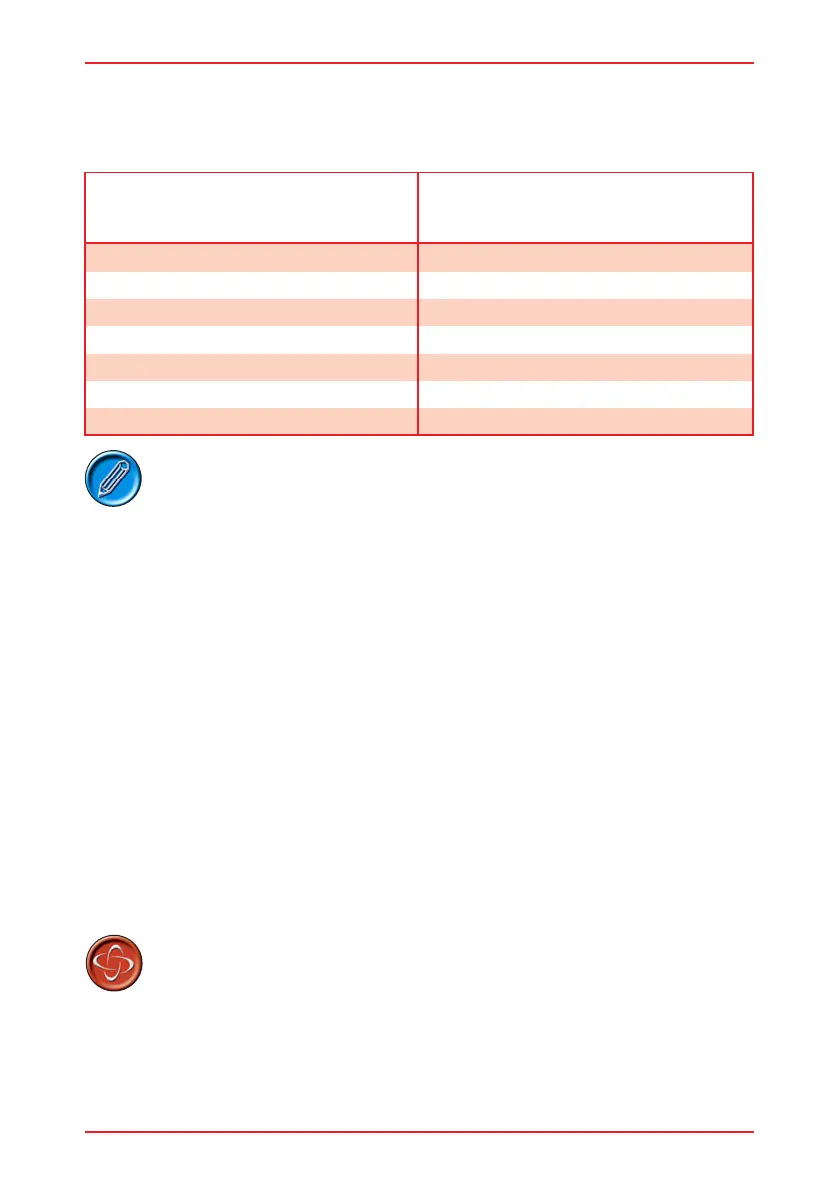

Connections Wire Gauge

Battery Wires

Motor Wires

On Board Charger Wires

Inhibit Wires

Actuator Wires

4.0mm

2

4.0mm

2

Battery Wires (VR2 40/50)

Motor Wires

VR2 40/50

2.5mm

2

2.5mm

2

1.0mm

2

0.5mm

2

1.0mm

2

Loading...

Loading...