Hydraulic connections

Anti-freeze concentration in the system

Correction factor

% Monoethylene glycol inhibited 10% 20% 30% 40%

Freezing temperature * -4 °C -9°C -15 °C -23 °C

Capacity 0,996 0,991 0,983 0,974

Power absorbed 0,990 0,978 0,964 1,008

Pressure drop 1,003 1,010 1,020 1,033

1RWHWKHWHPSHUDWXUHYDOXHVDUHLQGLFDWLYH$OZD\VUHIHUWRWKHWHPSHUDWXUHVJLYHQIRUWKHVSHFL¿FSURGXFWXVHG

Maximum percentage of glycol 40%

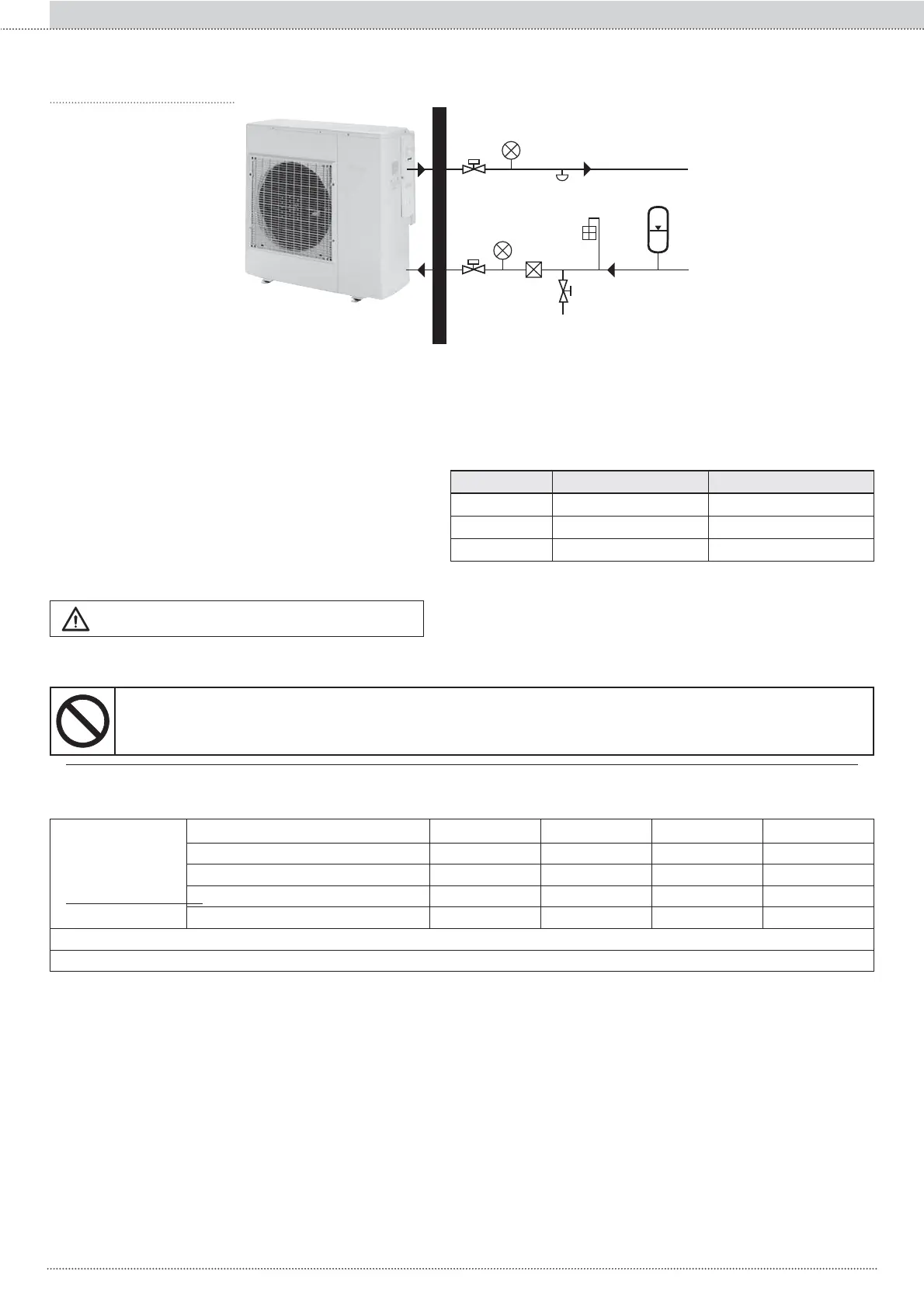

9.5 HIDRAULIC CONNECTIONS

1 shut-off valves

2 ZDWHUOLQH¿OWHU0,8 meshes/cm

2

)

3 pressure gauge

4 ¿OOLQJYDOYH

5 system drain valve (in the lowest points of the circuit)

6 air bleed valve (in the highest points of the circuit)

7 expansion tank

Do not use the heat pump to treat industrial process water, swimming pool water or domestic water.

Set-up an intermediate heat exchanger for all the above cases.

CAUTION

• The quantity of water in the system (pipes+terminals+tank) should not be less than the values shown in the table.

• The expansion tank is charged to the installer.

Model Minimum content (l) Maximum pressure (Bar)

105 30 3

110 40 3

116 60 3

The water connections must be implemented in accordance with the

layout and requirements provided by the heating system designer, in com-

pliance with the water input and output of the pump. The hydraulic circuit

must be set up according to the following recommendations:

• The pressure gauges must be installed to monitor the water pressure in the

system.

• It is recommended to install shut-off valves that allow the most important

components of the system to be isolated.

These valves, which can be ball, globe or throttle type, must be sized for the

least pressure drop possible when in the open position.

• The system must be equipped with drain systems in the lowest points.

• Air vents must be installed in the highest parts of the system.

• All piping must be adequately supported and isolated.

• The presence of solid particles in the water can obstruct the heat exchan-

ger. Therefore, the heat exchanger input must be protected with a removable

PHVK¿OWHU7KHVL]HRIWKHKROHVLQWKHPHVK¿OWHUPXVWEHDWOHDVWOLQNV

cm

2

.

• After assembling the system and after any repairs, it is important to thorou-

ghly clean the entire system, paying particular attention to the condition of

WKH¿OWHU

• An automatic anti-freeze protection system is installed, which:

- activates the circulator when the outdoor temperature is below 4°C

- starts the compressor when the water temperature is below 2°C.

Enable this protection by moving dip switch 1, found on the PDB DISPLAY,

to ON.

90

Section II :: Installation and maintenanceEN

Loading...

Loading...