1. Installation Method

1-2

2) Checking the Installation Conditions

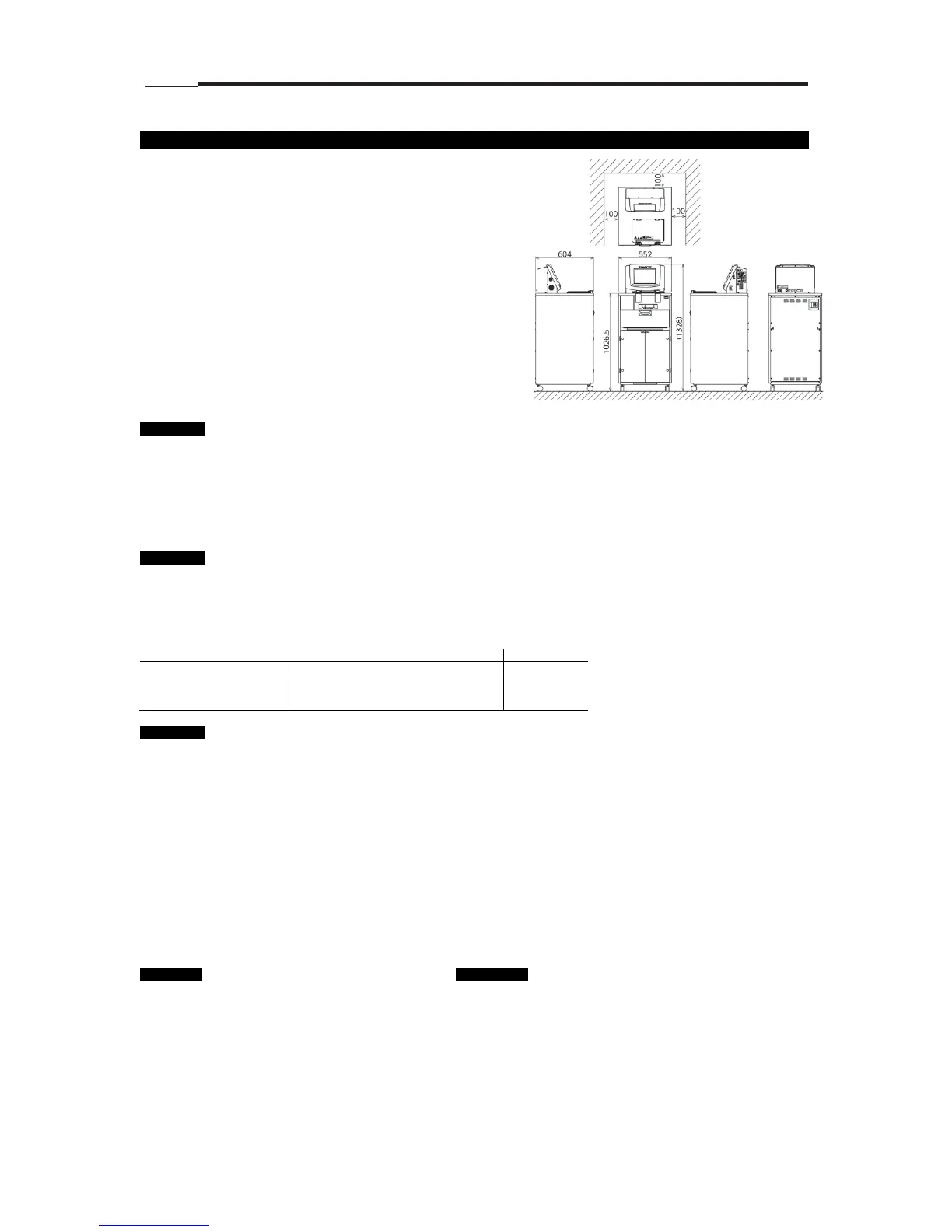

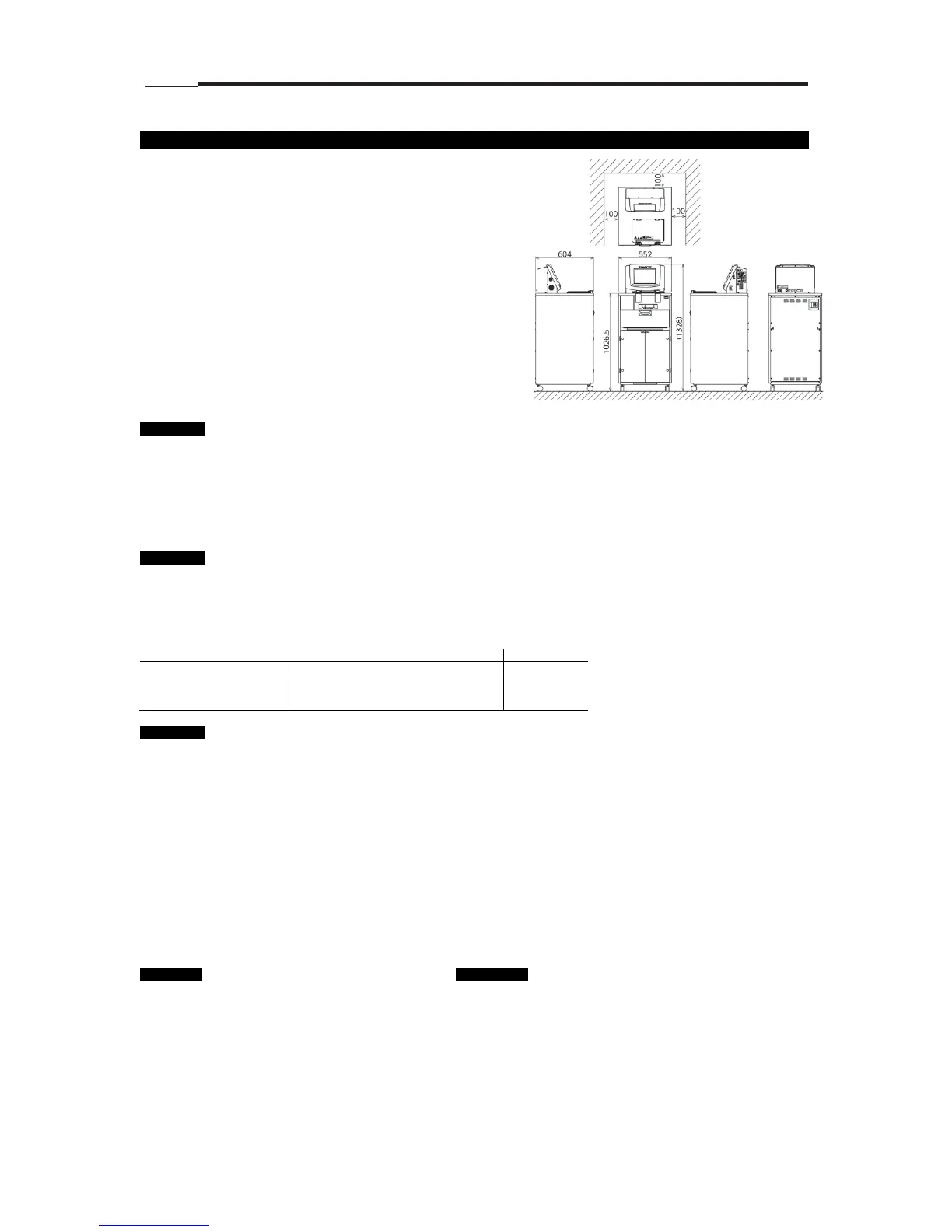

Checking the installation location

Confirm beforehand that the location is flat, strong and meets

the dimensions of installation location (installation space)

shown in the figure on the right. Also confirm that no space is

left at the rear of the instrument which will be used for people

to pass through frequently (recommended). Confirm that no

foreign objects that may block the air outlets of the instrument

(such as hanging towels, etc.) are present in and around the

installation location.

Checking the facility-side power supply

Confirm that the facility-side power supply conforms to the

requirements.

The instrument can support the power supplies listed below using the selector switches.

Switching of the voltage setting should only be performed by qualified service staff working exclusively

with the instrument.

• Single-phase 100 VAC 10%

• Single-phase 15 VAC 10%

• Single-phase 220 VAC ~ 240 VAC 10%

If the above facility requirements are not satisfied (such as when the power supply used is 200 VAC),

the instrument must not be used.

If the instrument generates abnormality, the breaker on the facility side may actuate and other

equipment may be affected; accordingly, connect each instrument to a dedicated power outlet

(including a dedicated breaker on the facility side).

• Specification of the power cord supplied with the instrument

UL/CSA, PSE approved product

Cord: CENELEC HD, VDE approved

Plug: EN, IEC, VDE

Connector: EN, VDE approved

If the instrument is used in a region where the applicable standard above is not met, provide a different

power cord conforming to the standard in the location of use.

• About grounding

Confirm with the person responsible for the facility that the power outlet to be used is grounded (100 or less).

Confirming a ventilation system, local exhaust system or exhaust port on the facility side

Although the volumes of volatile solution gases released from the instrument vary depending on the solutions

and processing programs used and the environmental temperature, volumes of gases released per unit time are

provided below for reference. Based on these values and the volumetric size of the installation location, check if

the ventilation rate is sufficient to meet the requirements at the installation location pertaining to the

concentrations of substances in the work environment. If ventilation facility is not available, connect the optional

duct connection adapter and exhaust duct hose set to the exhaust port of the instrument so as to release the

exhaust gases to the outdoors, or otherwise confirm that the instrument can be operated in such a way that the

concentrations of volatile solution gases in the work environment meet the standards at the installation location.

Maximum volumes of gases released per

unit time (reference)

Formaldehyde: 10.40×10

-6

(m

3

/hr)

Ethanol: 1.02×10

-2

(m

3

/hr)

Xylene: 4.05×10

-4

(m

3

/hr)

The volumes of volatile solution gases released

from the instrument vary depending on the

solutions and environment.

Loading...

Loading...