Installation manual

HB-37420-810-01-25F-EN PSC1-C-100 Installation manual - V2.2.docx Page 181 of 201

Version: 38F

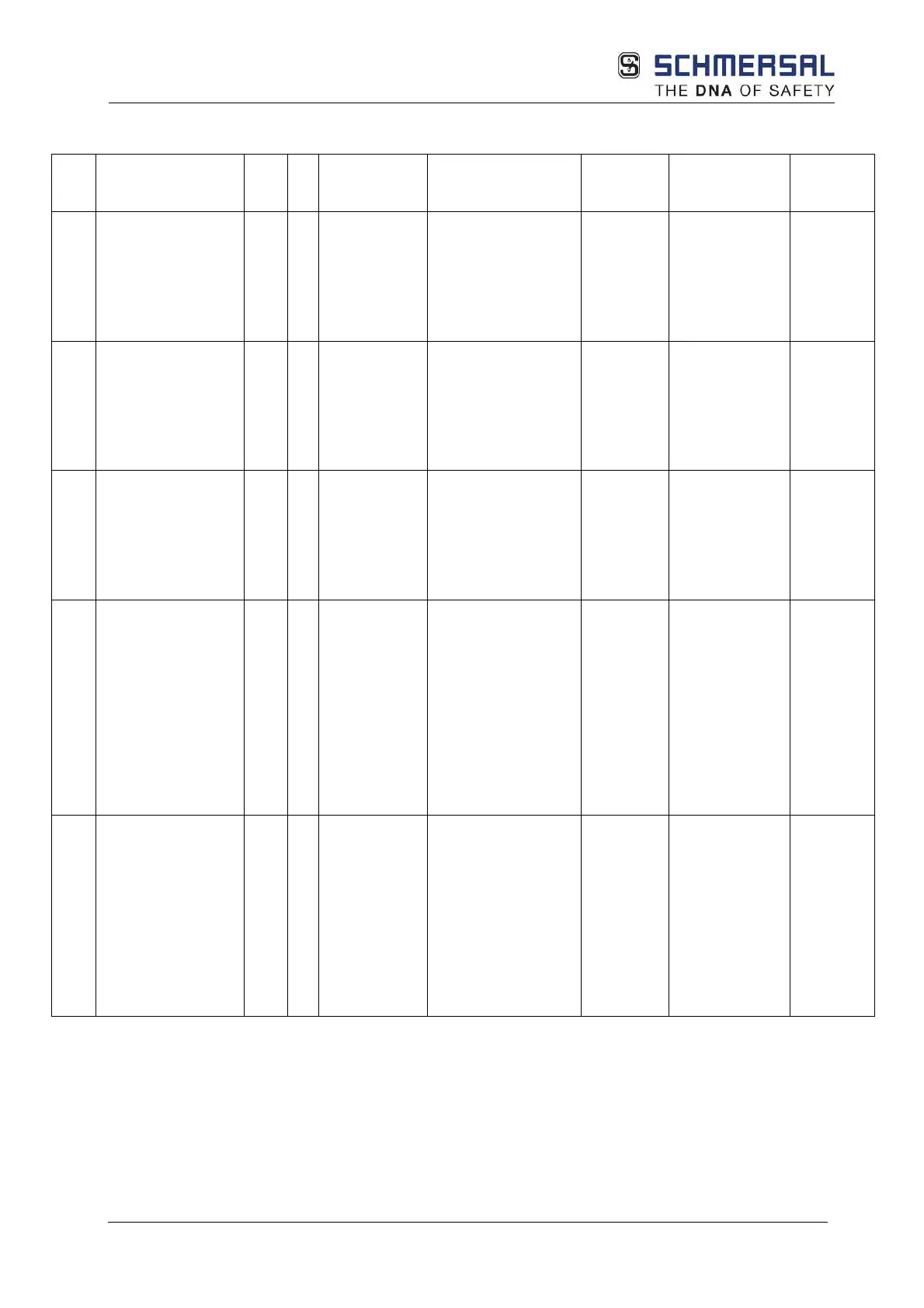

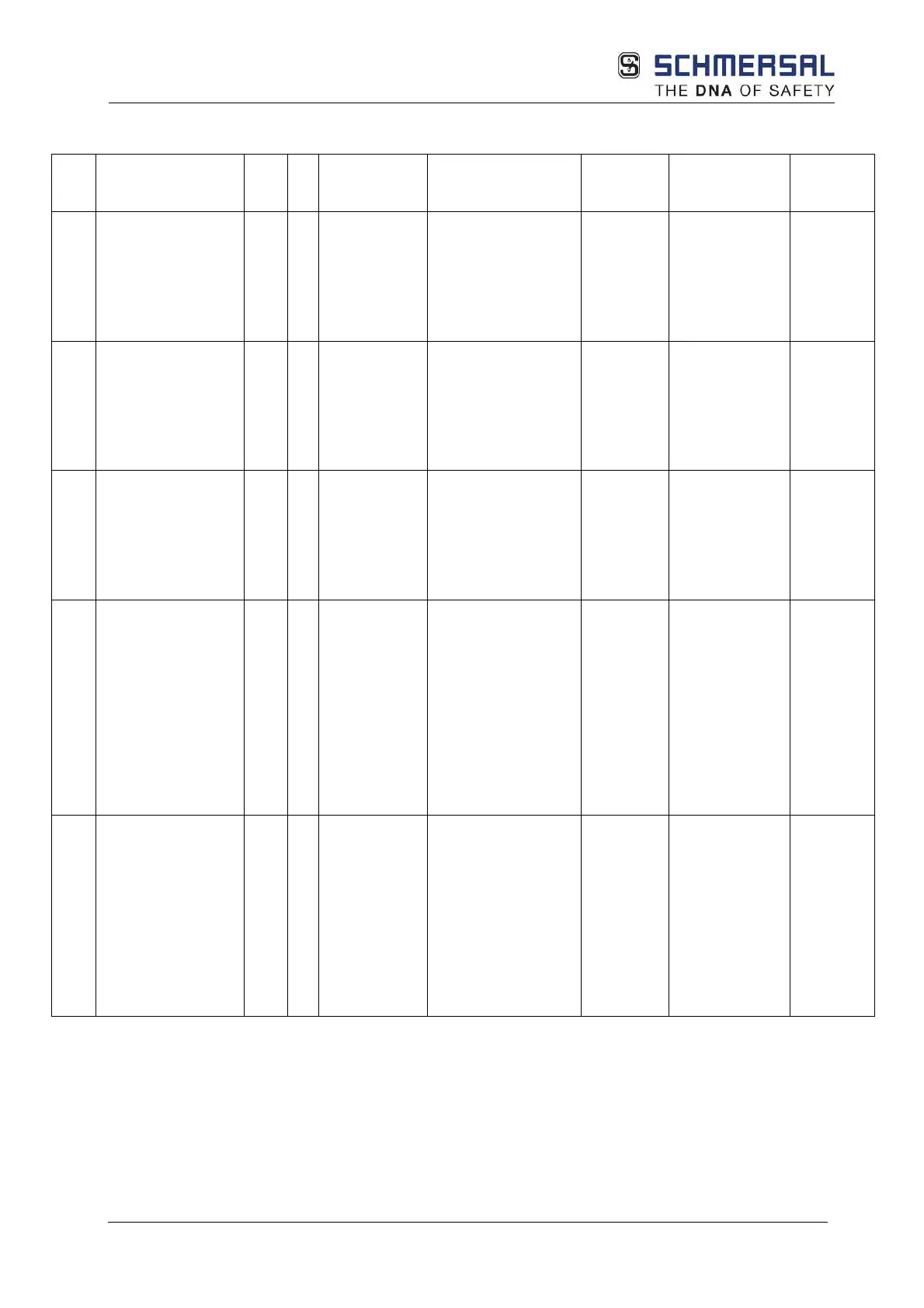

12.3.3.3 Example – specification of the safety functions in tabular form

Seq.

no.

Safety function Ref.

fro

m

P

L

r

Measured

value /sensor

Implementation in

software

Required

Parameter

Input/

activation

Response/

output

1.1 Limitation of the max.

speed of movement,

Monitoring of the

maximum speed

2.3 e 1 x WCS

absolute

encoder

1 x incremental

encoder on

motor / drive

wheel

Monitoring using tested

safety function SLS for

fixed limits:

550mm/s

Overspeed

distance

monitoring:

200mm

Continuous

Reset:

Reset button

Operation

stop

SF 1.7.1

1.2 Limitation of the max.

speed of movement of

the running gear in

working area of worker

Monitoring of the

maximum speed for <

0.33 m/s

2.4 e 1 x WCS

absolute

encoder

1 x incremental

encoder on

motor / drive

wheel

Monitoring using tested

safety function SLS for

fixed limits:

60 mm/s

Overspeed

distance

monitoring:

200mm

Identification of

working area of

worker via position

of running gear

AND NOT

setting up

Reset:

SF 1.7.1

1.3 Limitation of the max.

speed of movement of

the running gear in the

setting up mode

Monitoring of the

maximum speed for <

0.07 m/s

3.1 d 1 x WCS

absolute

encoder

1 x incremental

encoder on

motor / drive

wheel

Monitoring using tested

safety function SLS for

fixed limits:

70mm/s

Overspeed

distance

monitoring:

200mm

Setting up

operating mode

AND "Bypass

safety" button

Reset:

Reset button

SF 1.7.1

1.4 Running gear collision

protection

Monitoring of the

distances for minimum

distance using

redundant laser

distance measurement

2.5 d 2 x laser

distance

measuring

devices

Monitoring of the

distances using tested

SAC function.

The analogue distance

measured values are

compared mutually for

max. tolerance

(analogue sensor

diagnostics)

Monitored for minimum

values (SAC function)

Min. distance value 25%

of the max. value for

Running gear

outside working

area of the worker

Reset:

Reset button

SF 1.7.1

1.6.1 Running gear sensor

system monitoring

* for the two running

gear sensors

5.1 e 1 x WCS

absolute

encoder

1 x incremental

encoder on

motor / drive

wheel

Muting of the

diagnostics for both

running gear sensors

using tested SCA

function

Muting is started before

each gap, an incorrect

encoder value is then

briefly suppressed.

In the gap, an encoder

value outside of 2 to

160000 mm results in

muting

Pos 1

(7626 - 7850)

Pos 2

(11030-1263)

Pos 3

(75134-5338)

Pos 4

(145562-145622)

Pos 5

(143935-143995)

Pos 6

(80000-80060)

SF 1.6.2

Loading...

Loading...