9. RUNNING THE CYCLE

42. .

Drying

Ventilation

Leveling to the

atmospheric pressure

Completion

of the cycle

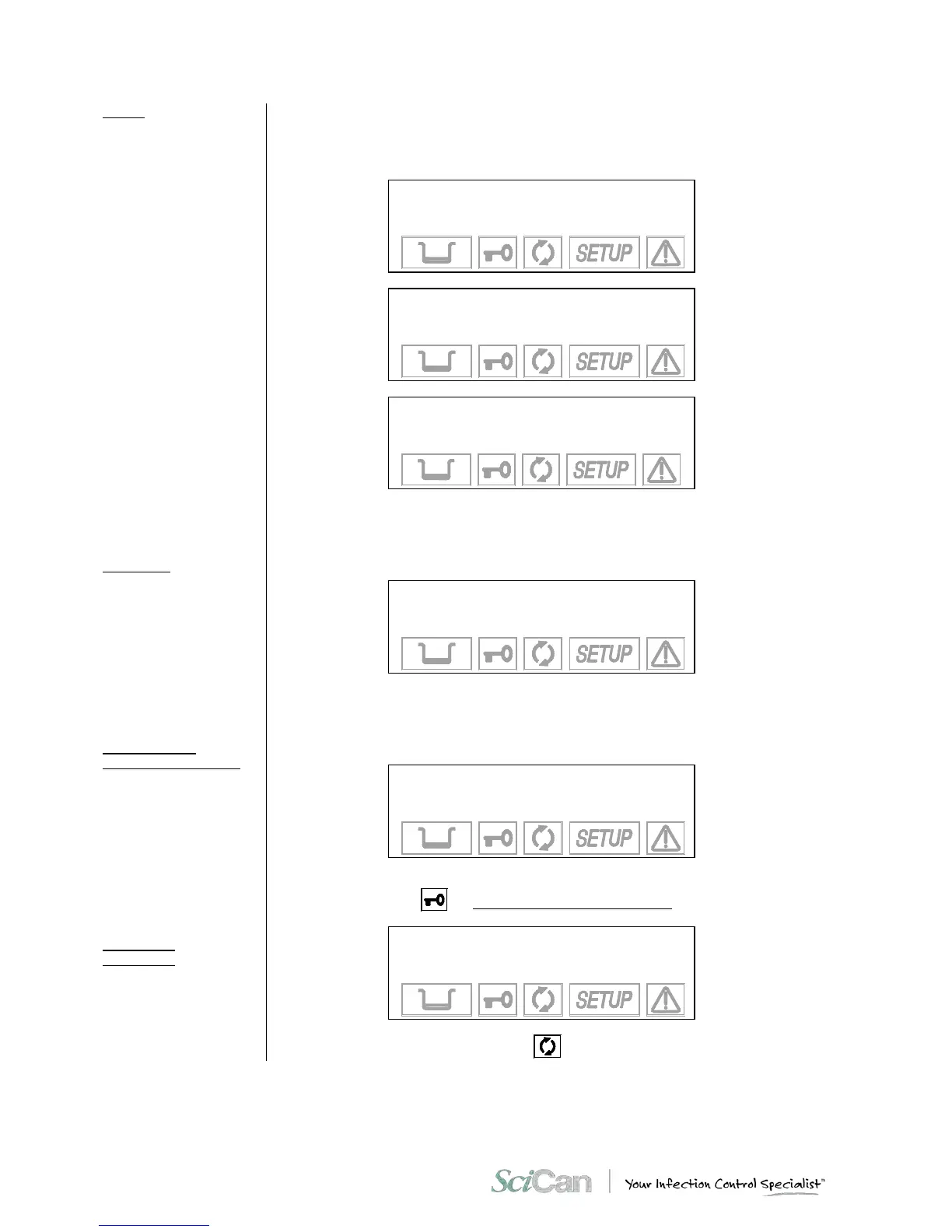

After the steam under pressure is released, the vacuum pump turns on to begin the drying

phase (DRYING). This creates a low pressure in the sterilization chamber to facilitate the

evaporation and consequent elimination of the steam. Depending on the type of drying

selected, one of the following screens will appear:

1 134 POROUS/ WRAPPED

DRYING (NOR)

101.1 °C

0.00 bar 18:51

1 134 POROUS/ WRAPPED

DRYING (INT)

101.1 °C

0.00 bar 18:51

1 134 POROUS/ WRAPPED

DRYING (+XX)

101.1 °C

0.00 bar 18:51

When the drying phase is complete, it is followed by a VENTILATION phase in which sterile,

fresh air is injected, while maintaining a vacuum in the chamber, to eliminate condensate and

cool the load.

1 134 POROUS/ WRAPPED

VENTILATION

84.4 °C

- 0.77 bar 26:51

At the end of the ventilation phase, the chamber is brought back to atmospheric pressure

(LEVELLING) by injecting sterile outside air to allow the opening of the door and the retrieval

of the load.

1 134 POROUS/ WRAPPED

LEVELLING

86.9 °C

- 0.43 bar 29:21

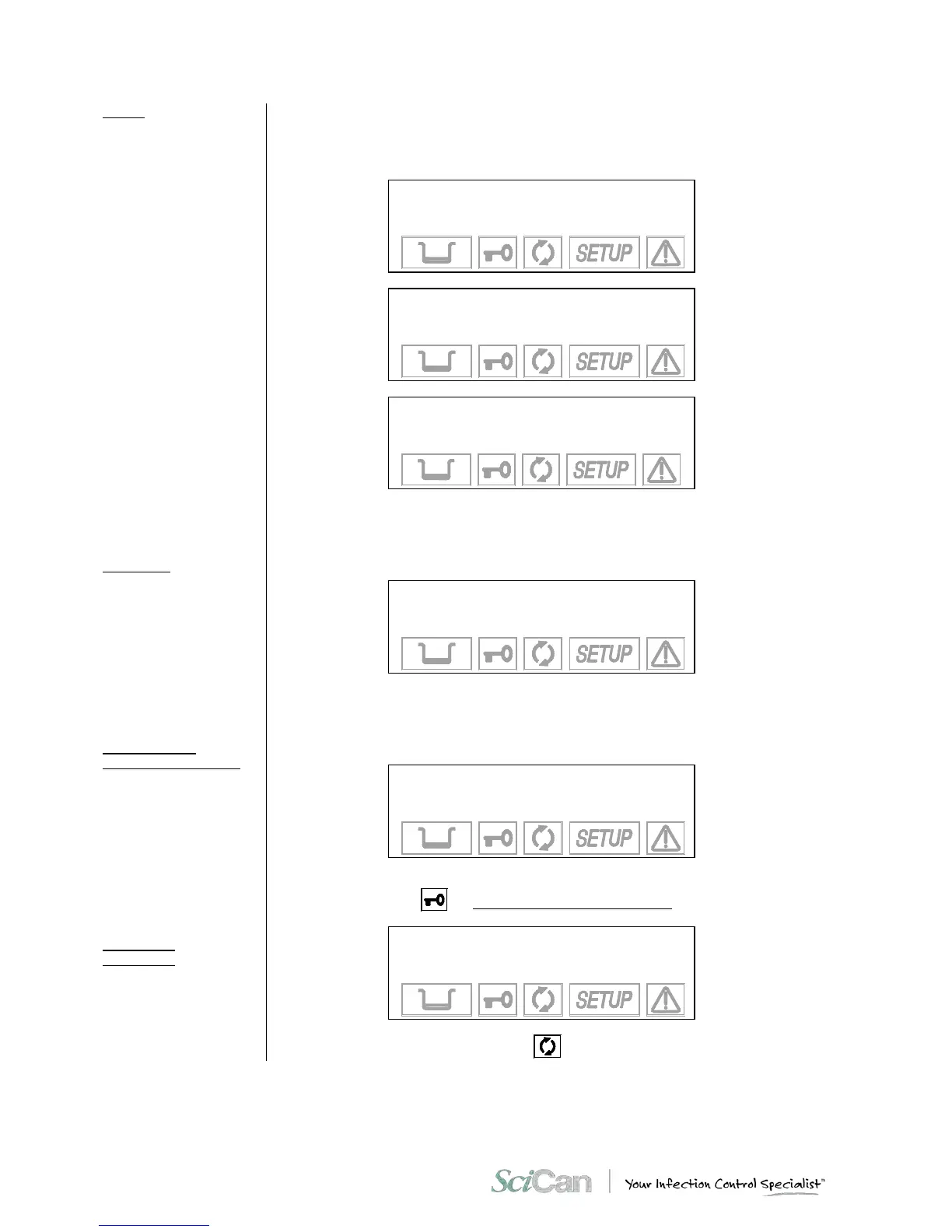

When the drying cycle is completed and the chamber pressure returns to pre-set safety limits,

the door status indicator will flash, the unit will beep and the door will unlock.

1 134 POROUS/ WRAPPED

CYCLE COMPLETE

86.2 °C

- 0.02 bar 29:40

The icon for the sterilization process status stays on.

Loading...

Loading...