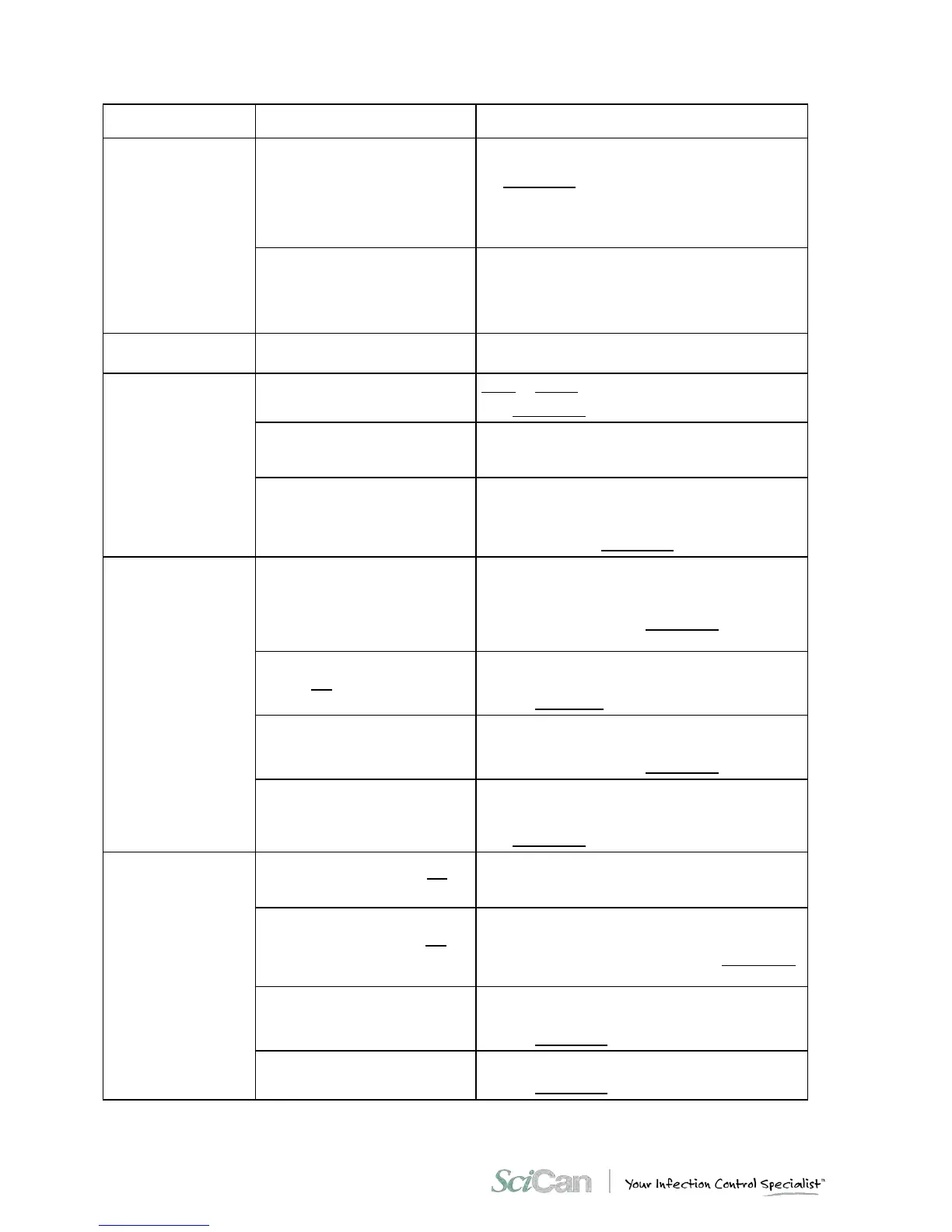

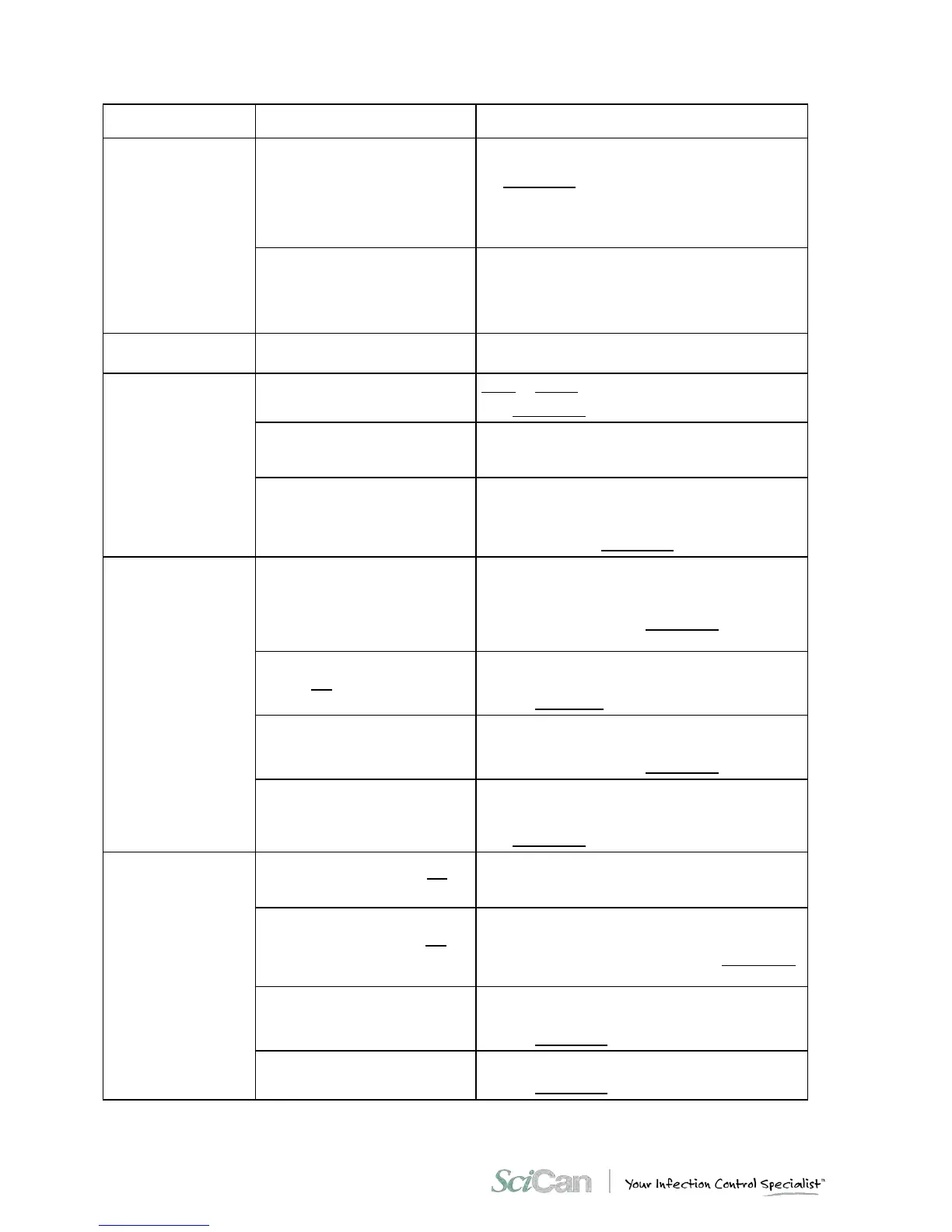

APPENDIX D – TROUBLESHOOTING

70. .

The water supply tube from the

external tank (optional) is not well

connected.

Check the tightness of the connector; if necessary,

reassemble, paying greater attention to sealing (see

the Chapter 4 - “Installation”).

Check that the tube coming from the external tank is

completely pushed onto the connector; make sure that

the plastic tie has been applied.

Steam leaks from the gasket.

At the end of the cycle, clean the gasket and porthole

of the container under pressure. Check if the gasket is

damaged.

Run another cycle and check the situation. If the

gasket still leaks, replace it with a new one.

There is water around

the drain tank.

Drain tubes (optional drain tank) not

correctly connected to the tank.

Check that the tubes connected to the drain tank are

correctly and completely pushed onto the connectors.

The sterilizer has

problems creating a

vacuum in the chamber

(drying problems,

presence of water in the

sterilization chamber at

the end of the cycle,

etc.).

Drain filter of the sterilization

chamber obstructed.

Clean or replace the drain filter.

(See Appendix C “Maintenance”).

Drain circuit obstructed or drain

tubes choked (optional drain tank).

Check that the drain tubes (and the connectors they

are pushed onto) are not obstructed and run freely

from the device to the tank.

The air intake on the frame and/or

the cover is obstructed or the heat

exchanger is not sufficiently

ventilated.

Remove all possible obstructions from the air intake

and heat exchanger.

Check that the device is not in direct contact with walls

or surfaces (see the Chapter 4 - Installation).

Excessive humidity on

the material and/or

instruments at the end

of the program.

There is too much material inside

the sterilization chamber.

Check the quantity of material sterilized and make sure

that it does not exceed the maximum allowed quantity,

depending on the type of load.

(See the Summary Table in Appendix A, Technical

Characteristics).

Material not correctly positioned.

Position the material, and especially wrapped material,

according to the instructions.

(See the Chapter 7 - Preparing the Material).

Wrong sterilization program

selection

Select the appropriate sterilization program for the type

of material to be treated.

(See the Summary Table in Appendix B, Programs).

Drain filter of the sterilization

chamber obstructed.

Clean or replace the drain filter.

Check for kinks in the exhaust tube, if being used.

(See Appendix C Maintenance).

Traces of oxidation or

spots on instruments

Quality of the instruments is not

adequate.

Check the quality of the instruments with the problem,

checking whether the material they are made of can

tolerate steam sterilization.

Quality of the distilled water not

adequate.

Empty the tank and fill it with high-quality distilled

water.

(See the Water Supply Characteristics in Appendix A,

Technical Characteristics).

Organic or inorganic residues on

the instruments.

Carefully clean the material before subjecting it to the

sterilization cycle.

(See the Chapter 7 - Preparing the Material).

Contact between instruments made

of different metals.

Separate instruments made of different metals.

(See the Chapter 7 - Preparing the Material).

Loading...

Loading...