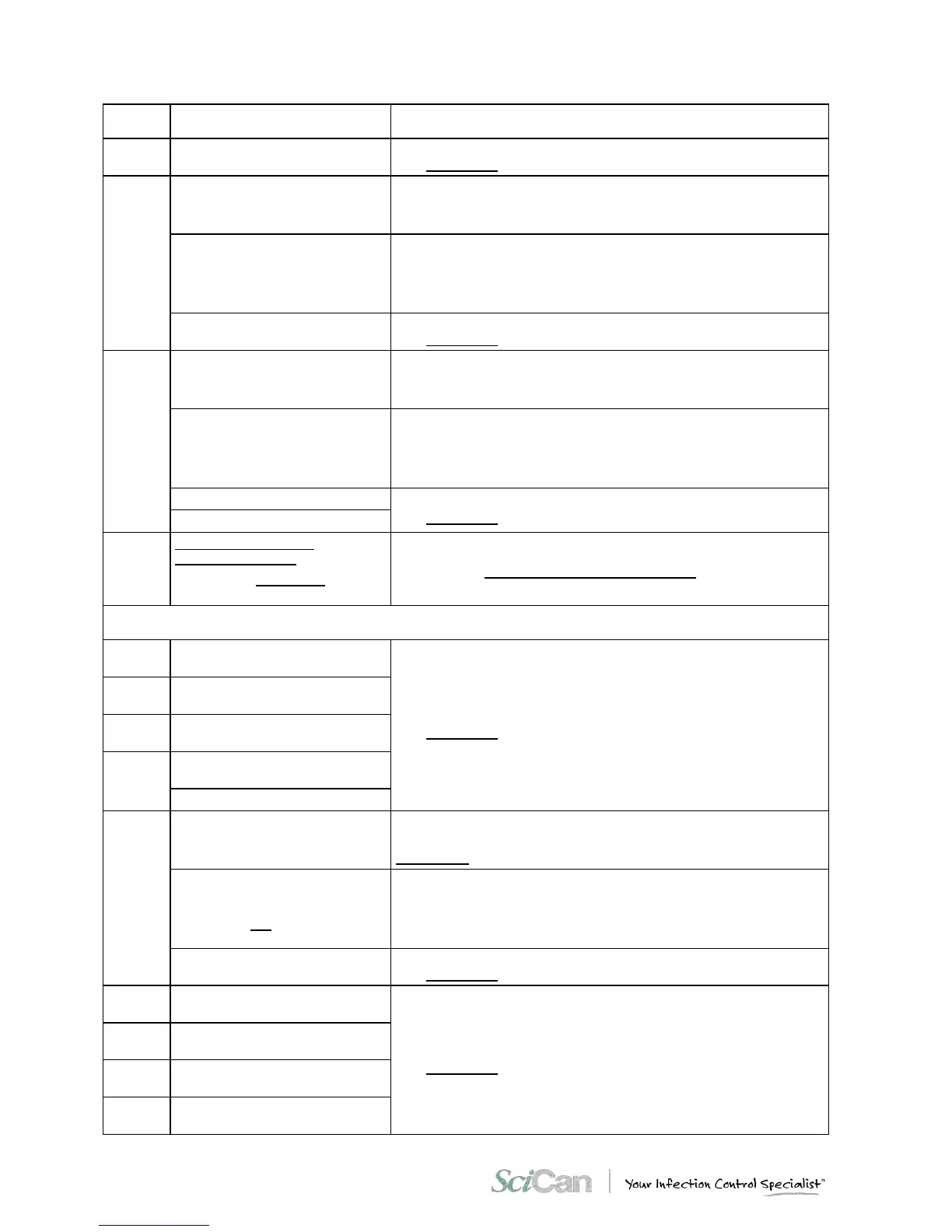

APPENDIX E – AL A RM S

78. .

Problem in the plumbing circuit.

Contact the Technical Support Department

(see Appendix Z).

Excessive humidity in the

sterilization chamber.

Perform RESET following the instructions.

Carefully dry the inside of the sterilization chamber and start the program

again.

Air leaking through the gasket

Perform RESET following the instructions.

Carefully clean the gasket with a clean cotton cloth dampened with

water.

Start the program again. If the gasket still leaks, replace the gasket.

Problem in the plumbing circuit.

Contact the Technical Support Department

(see Appendix Z).

Excessive humidity in the

sterilization chamber.

Perform RESET following the instructions.

Carefully dry the inside of the sterilization chamber and start the program

again.

Air leaking through the gasket

Perform RESET following the instructions.

Carefully clean the gasket with a clean cotton cloth dampened with

water.

Start the program again. If the gasket still leaks, replace the gasket.

Contact the Technical Support Department

(see Appendix Z).

Problem in the plumbing circuit.

Manual interruption of

sterilization or test program.

(Also see the Chapter 9 -

“Running the Program”)

Perform RESET following the instructions.

Check that the load has been correctly sterilized, by reading the LCD

display, before using the material.

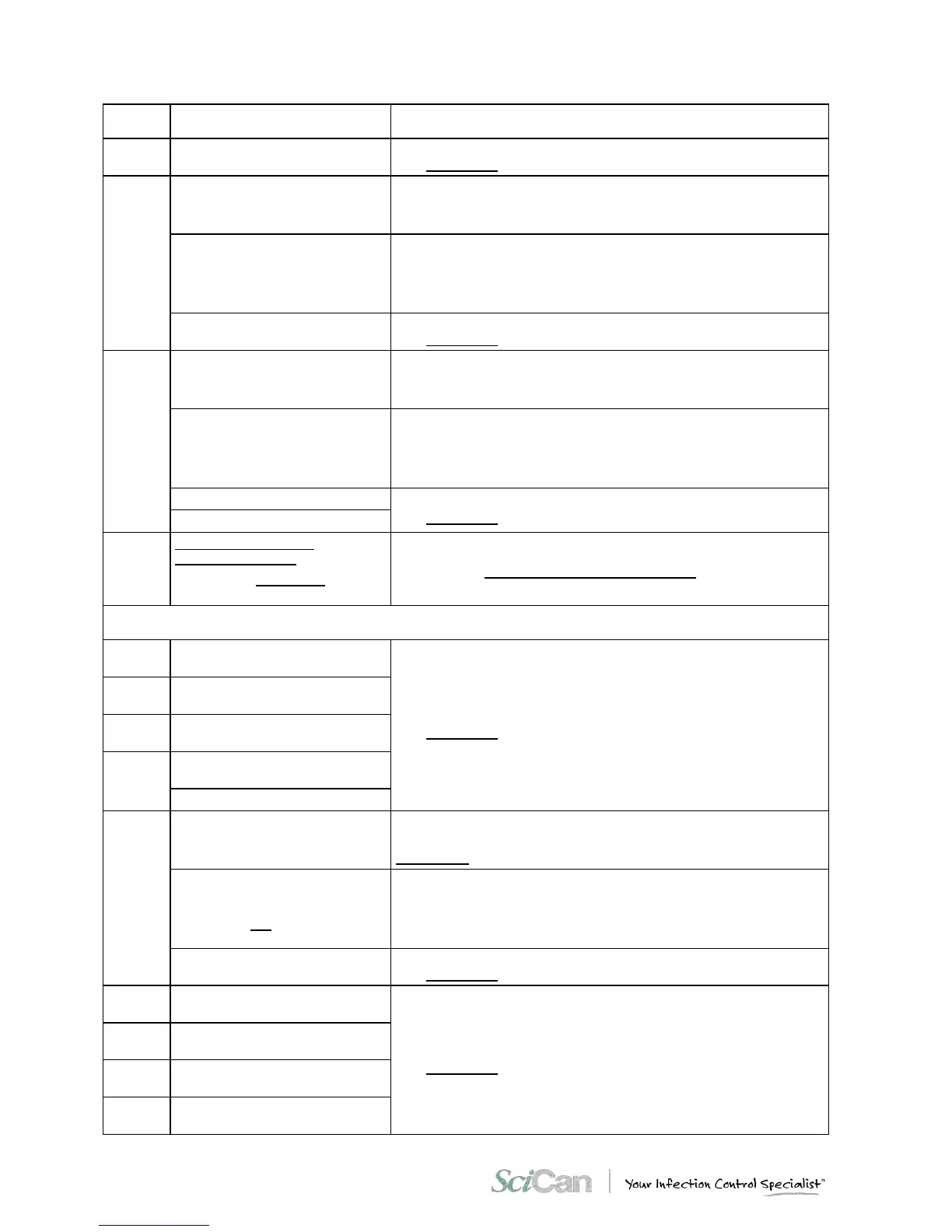

AL AR M S ( c at eg or y A)

Limit microswitch(es) on the door

lock mechanism broken.

Contact the Technical Support Department

(see Appendix Z).

Limit microswitch(es) on the door

lock mechanism broken.

Limit microswitch(es) on the door

lock mechanism broken.

Connector of the water level

indicators not connected.

Level indicator(s) broken.

Lack of water in the external tank or

Bravo Pure turned off (automatic

filling).

Perform RESET following the instructions.

Fill the tank with a sufficient quantity of water, remembering to

periodically check the level, or turn on the Bravo Pure.

Connection tube between the

sterilizer and a possible external

filling device not correctly installed.

Perform RESET following the instructions.

Check that the water supply tube is correctly and solidly connected to the

relative connectors.

Eliminate all possible obstructions along the path of the tube.

Water filling pump broken.

Contact the Technical Support Department

(see Appendix Z).

Chamber temperature sensor (PT1)

broken.

Contact the Technical Support Department

(see Appendix Z).

Steam generator temperature

sensor (PT2) broken.

Heating element temperature

sensor (PT3) broken.

Chamber wall temperature sensor

(PT4) broken.

Loading...

Loading...