5.1 Trouble shooting

114

(4)

Detector (TCD)

*1 If applying current to the filament with air still remaining in the TCD cell, you may oxidize or blow out the filament, which

makes the detector impossible to be zero adjusted. The damaged cell must be replaced. Contact your Shimadzu

representative.

*2 Cell conditioning procedures

(1)

Connect the column mounting port of dual packed INJ and the TCD column mounting port with a clean pipe (each

line).

(2)

Set the current value to "0 mA".

(3)

Supply carrier gas to both flow lines (30 to 50 ml/min).

(4)

Specify the detector temp. 30C higher than the one at analysis (Be careful. DO NOT exceed the maximum

operating temp., 400C).

The conditioning time varies from 1 to 12 hours depending on the degree of contamination.

Sometimes, the baseline may fluctuate since temperature or flow rate of each component is not yet stabilized. Check

the monitor screen and if this problem occurs, contact your Shimadzu representative.

*3 Applying excessively high current can damage the filament, which can cause significant noise. You need to replace the

damaged cell. Contact your Shimadzu representative.

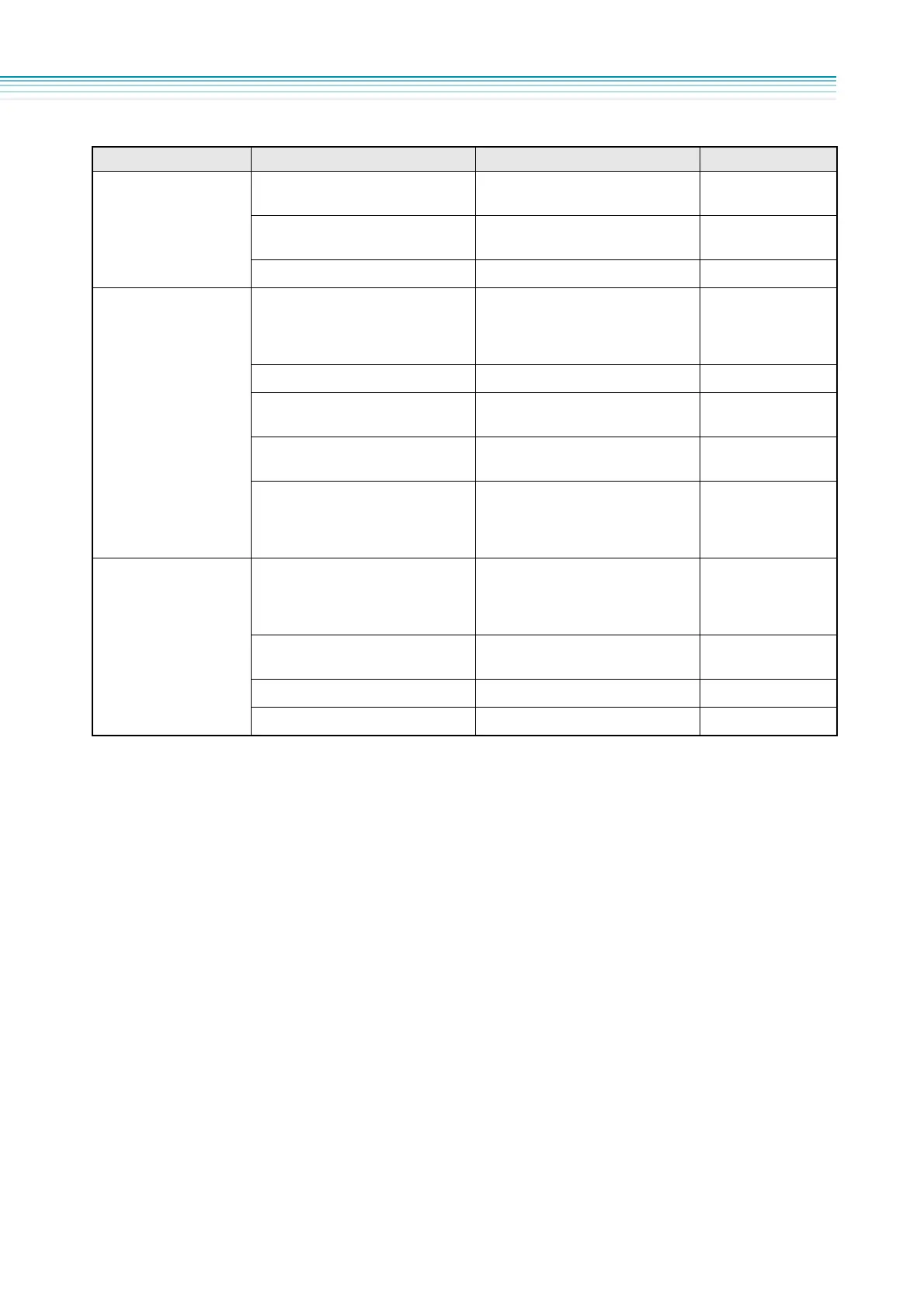

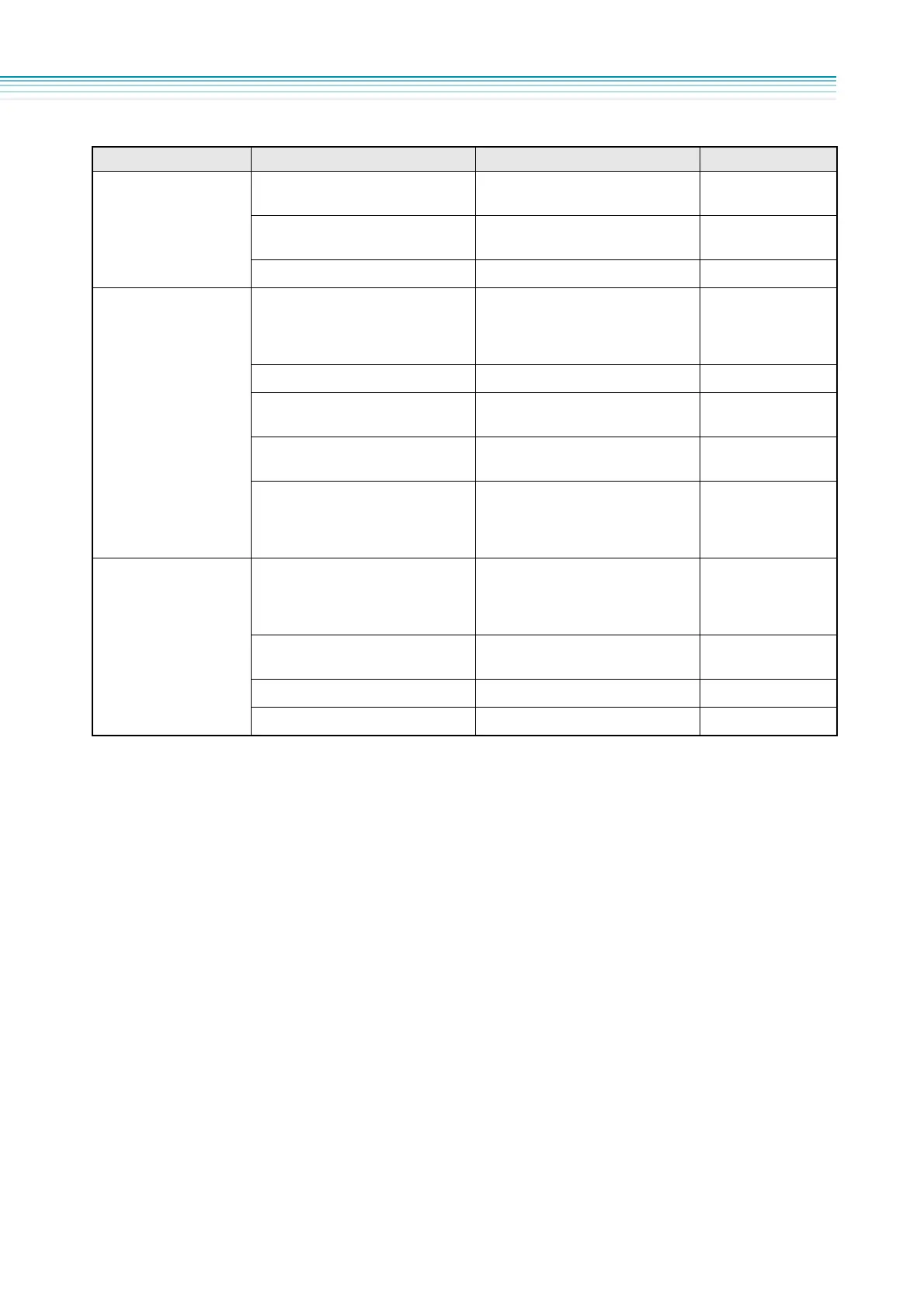

Problem Possible cause Solution Reference

The TCD cannot be

zero adjusted

Data processing unit is not

connected properly.

Connect it properly.

Current is not passing through

the filament.

Apply the current. *1

Current value is set too high. Reduce the current.

Baseline is fluctuating Carrier gas or makeup gas is

contaminated.

Purge air inside of flow lines

sufficiently.

Replace tubing parts.

Use a purer gas.

Current value is set too high. Reduce the current.

Injection ports (glass insert or

silica wool) or columns are dirty.

Cleanse or replace glass inserts.

Condition columns.

Cells are dirty. Condition the cells.

Inject solvent several times. *2

Room temperature is not within

the recommended range, or is

fluctuating considerably.

Keep the room temp. within the

recommended range and

stabilize the temp. at a certain

level.

A lot of noise or noise

level is high.

Carrier gas or makeup gas is

contaminated.

Purge air inside of flow lines

sufficiently.

Replace tubing parts.

Use a purer gas.

Gas is leaking. Check for leaks in injection port

and column connection area.

Current value is set too high. *3 Reduce the current.

Makeup gas flow rate is too low. Increase the flow rate.

Loading...

Loading...