Operating Instructions 5-3 M90 Fusion Splicer

Issue 02/97 Attenuation Splice

Operation of the Attenuation Splice Program

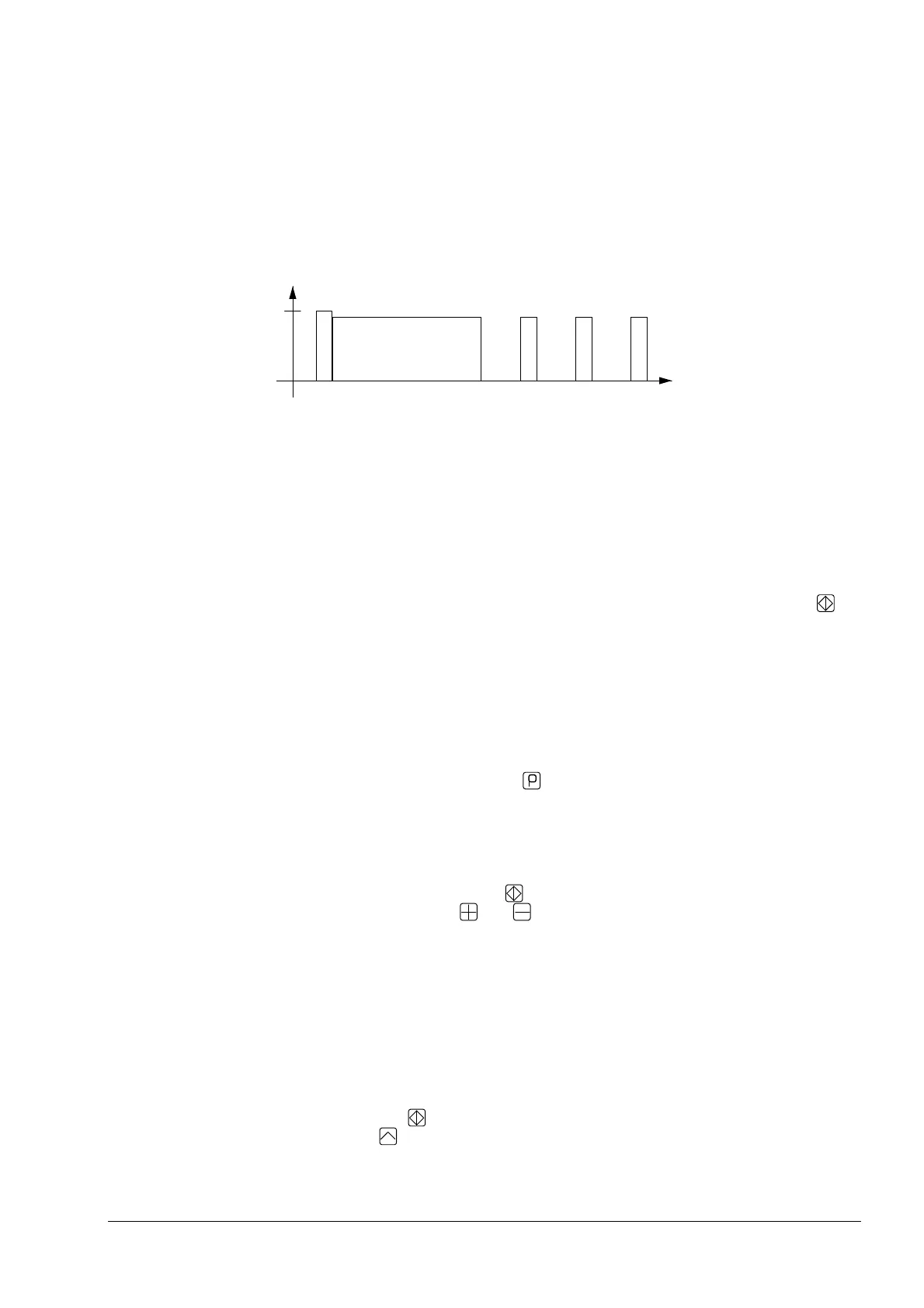

The fibers are positioned in the same way as with all LID programs. Immediately before

it commences fusion, the fusion splicer automatically sets a radial offset of the fiber

axes. The fusion process consists of an initial fusion phase followed by one or more

fusion pulses and runs fully automatically until the required attenuation is reached (see

drawing).

Fusion Process

A Fusion current

B Prefusion

C First fusion

phase

D Fusion pulse

E Time

Making an Attenuation Splice

Setting the de-

fault parameters

The default parameters stored in the fusion splicer provide the basis for all parameter

settings. You can set these parameters (for all programs jointly) by keeping button

depressed when you switch on the splicer. Please note, however, that you will then lose

the set parameters of all programs.

Program selec-

tion and adapt-

ing the parame-

ters

Use the Parameter menu to select the attenuation splice program and set the

"Attenuation" parameter to the required value. If you have set the default parameters

and are using standard fibers, you do not need to perform any further parameter set-

tings at this point. If you do not wish to set the default parameters or are using special

fiber types, refer to the Parameter Recommendations section.

Conclude parameter setting with button

.

Preparing fibers

If you use a heat-shrink splice protector, slide this over one of the two fibers. The fibers

are stripped, cleaved and inserted in the same way as with all other LID programs.

Setting the re-

quired attenua-

tion

Start the program by pressing button

. The set attenuation will be displayed. To

change the value, use buttons

and . This change then applies for the next splice

only. (You can change the default value in the Parameter menu.)

Starting the

splicing proce-

dure

Start the splicing procedure in the usual way. You can only select fully automatic /

automatic operation.

Fault message

"Bad endfaces"

If the fault message

"Bad endfaces"

is displayed during positioning, you can still con-

tinue the splicing process. In this case, however, you must expect an additional inaccu-

racy of approx. 0.1 to 0.2 dB in the attenuation displayed rsp. in the attenuation value

obtained. Press button

if you want to continue the splicing process or abort the pro-

cedure with button

.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...