Operating Instructions 5-7 M90 Fusion Splicer

Issue 02/97 Attenuation Splice

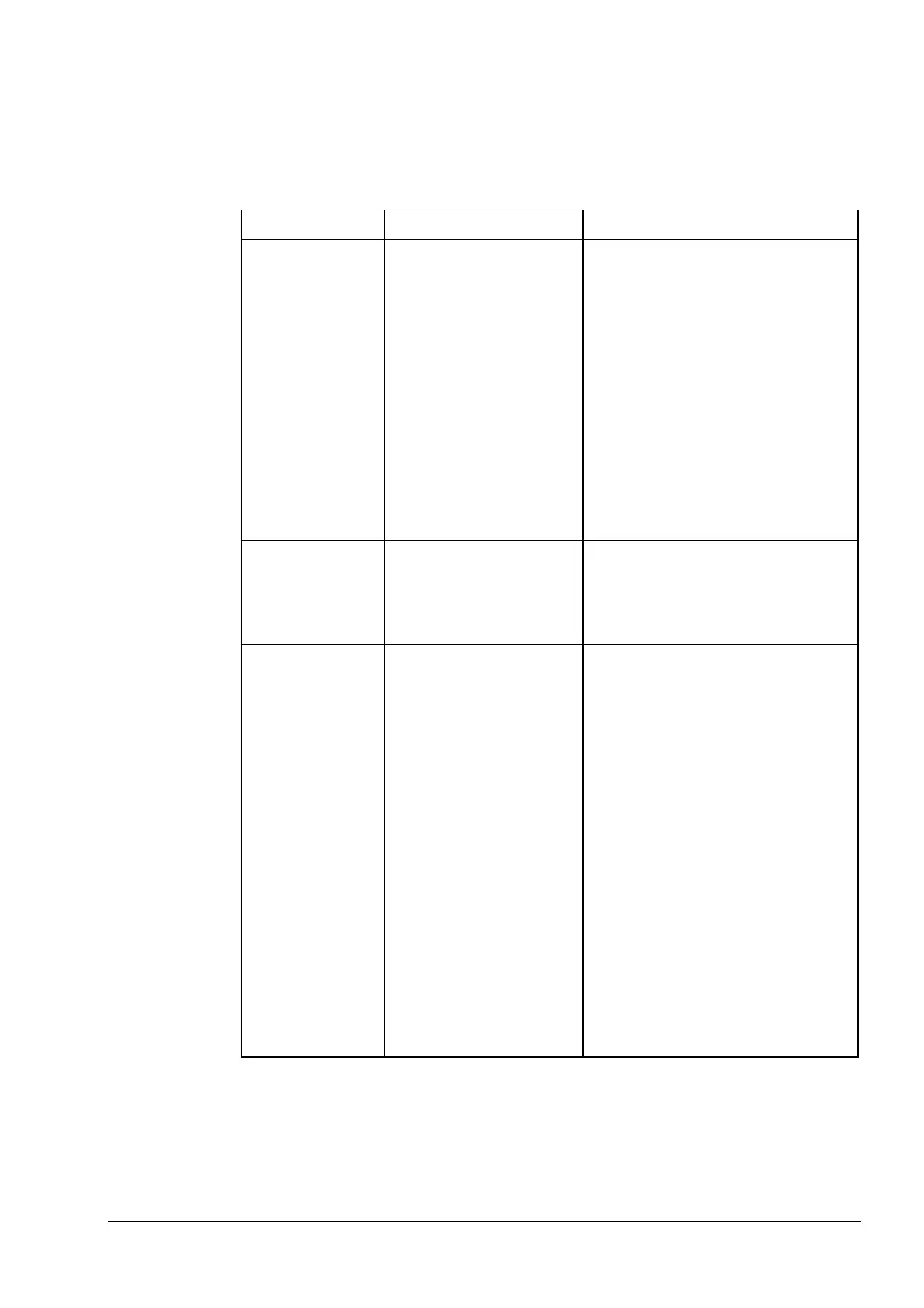

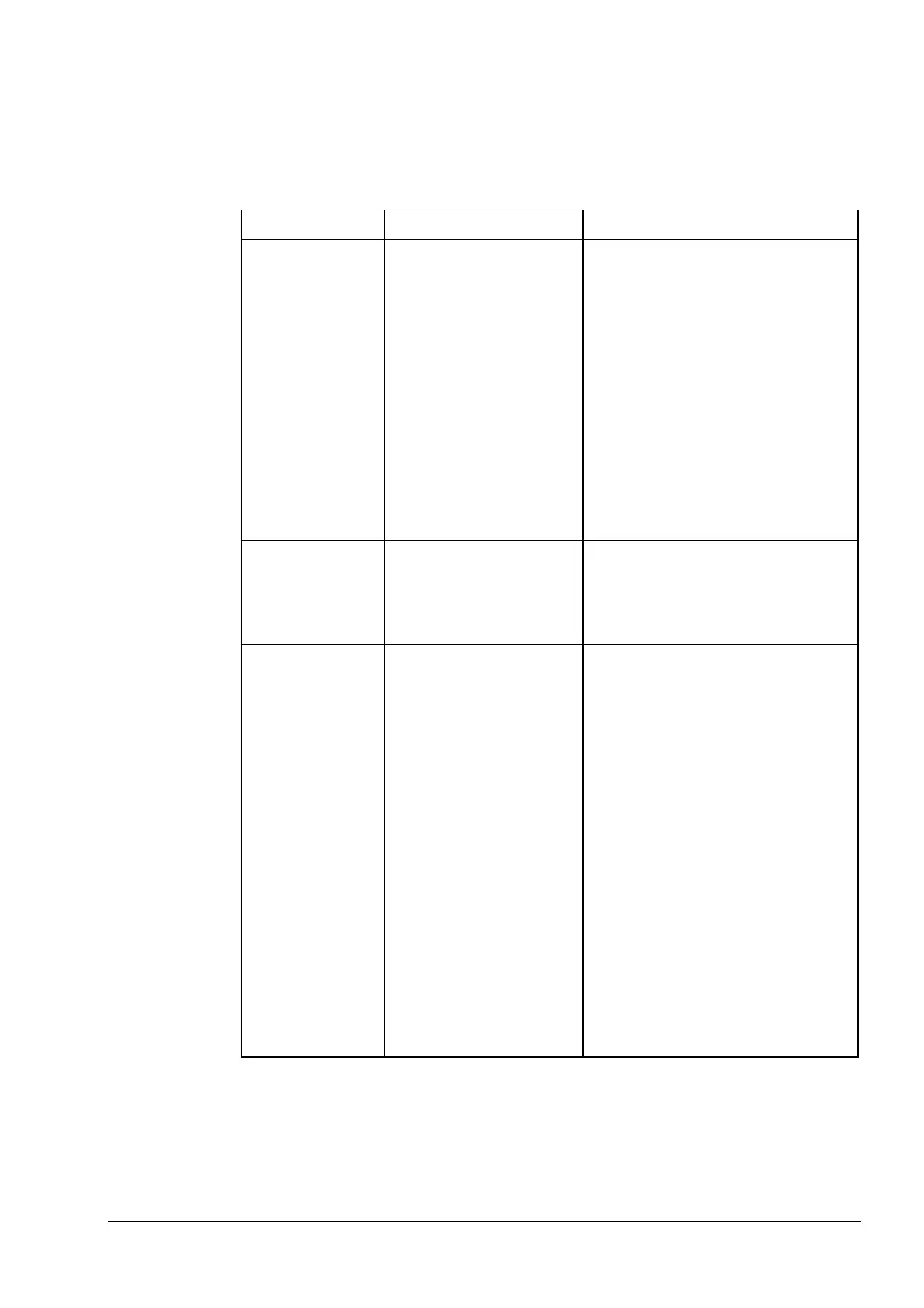

Possible prob-

lems

If the set attenuation is not obtained or the result is not sufficiently accurate, ensure first

that all parameters except the fusion current are set to provide good splice attenuation

results in the

Automatic Fusion Time

program. If this is the case, proceed as set out

in the following check list. Keep to the specified sequence and check the effect of each

change before proceeding with other changes.

Fault Symptom/

Possible Cause

Remedy

Attenuation too low.

The fusion pulses

are

not

generated.

The electrodes are not in-

serted as far as they can go

into the electrode holder or

they are very dirty.

Check and correct if necessary. The

electrodes must be clean and inserted as

far as they can go.

The fusion current is set too

high.

Ensure that the fusion parameters rec-

ommended for the given fiber type have

been set. The fusion current is to be set

0.5 mA lower than for normal splices.

Check the duration of the first fusion

phase. The fusion current must be set so

that it is applied for between 2 and 5 s.

The lead is too low

. If the lead recommended for the given

fiber type is set, increase this value in

steps of 5 %.

Attenuation too low.

The fusion pulses

are generated.

The actual value displayed

changes with each fusion

pulse by a high percentage.

The fusion pulses are too

long.

Reduce additional time in steps of 0.02 s.

Attenuation value

too high.

The process is

aborted after 20

fusion pulses.

The actual value displayed

changes only slightly from

one fusion pulse to the next.

The fusion current is set too

low.

Check the duration of the first fusion

phase. The fusion current must be set so

that it is applied for between 2 and 5 s. If

this is already the case, the cause may lie

in the additional time being too low (see

below).

After the first fusion phase,

the actual value is very much

smaller than the required

value. The actual value rises

markedly from one fusion

pulse to the next but does not

reach the required value.

The lead is too large.

Reduce the lead in steps of 5 %. If the

attenuation is then too low and no more

fusion pulses are generated, set the old

lead value again and increase the addi-

tional time in steps of 0.02 s.

The displayed actual value

changes only slightly from

one fusion pulse to the next

or falls.

The additional time is too

short.

Increase the additional time in steps of

0.02 s. If the attenuation falls below the

required value by an excessive amount,

the additional time was probably not too

short but rather the lead was too large.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...