M90 Fusion Splicer 7-22 Operating Instructions

Troubleshooting and Care/Maintenance Issue 02/97

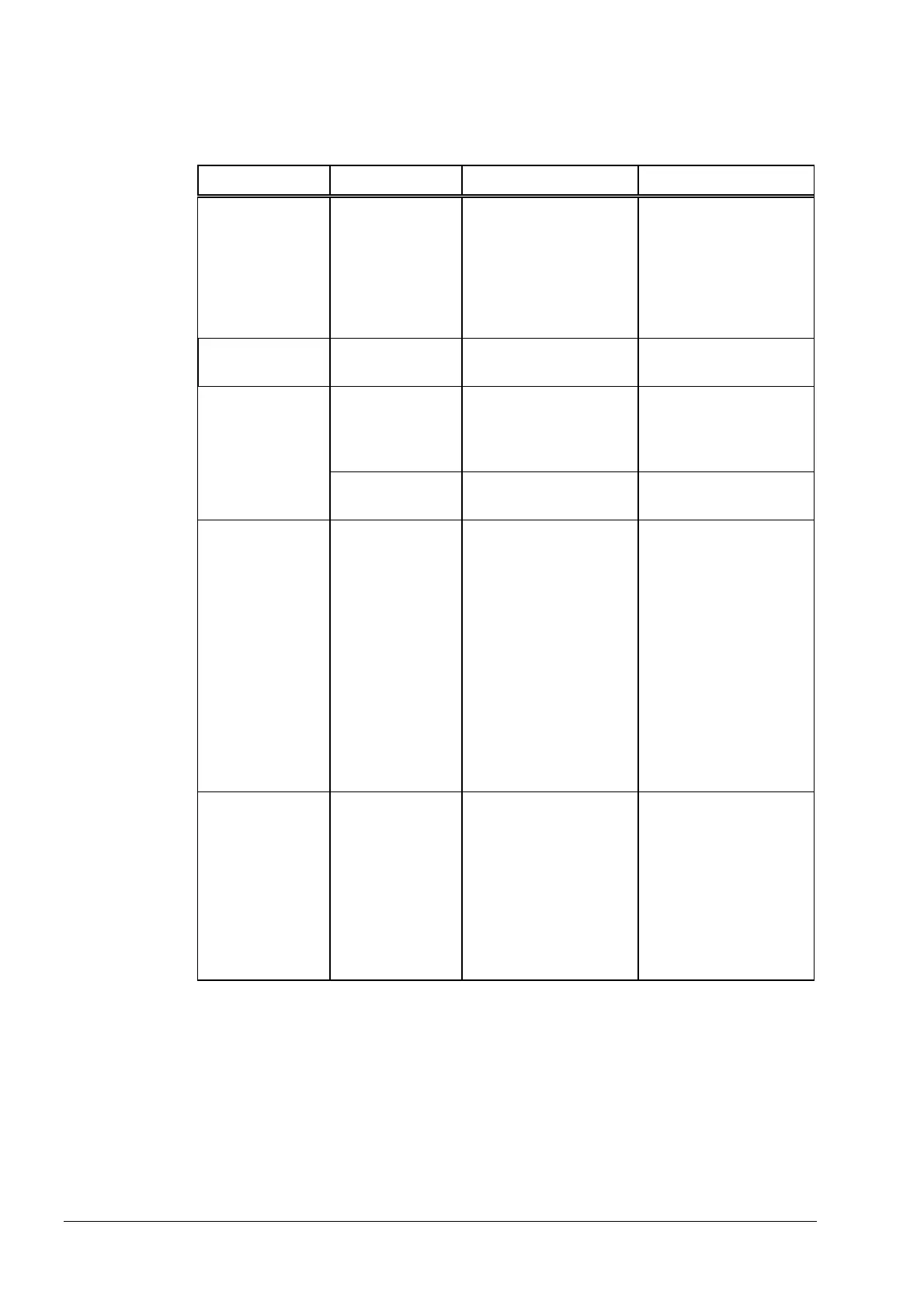

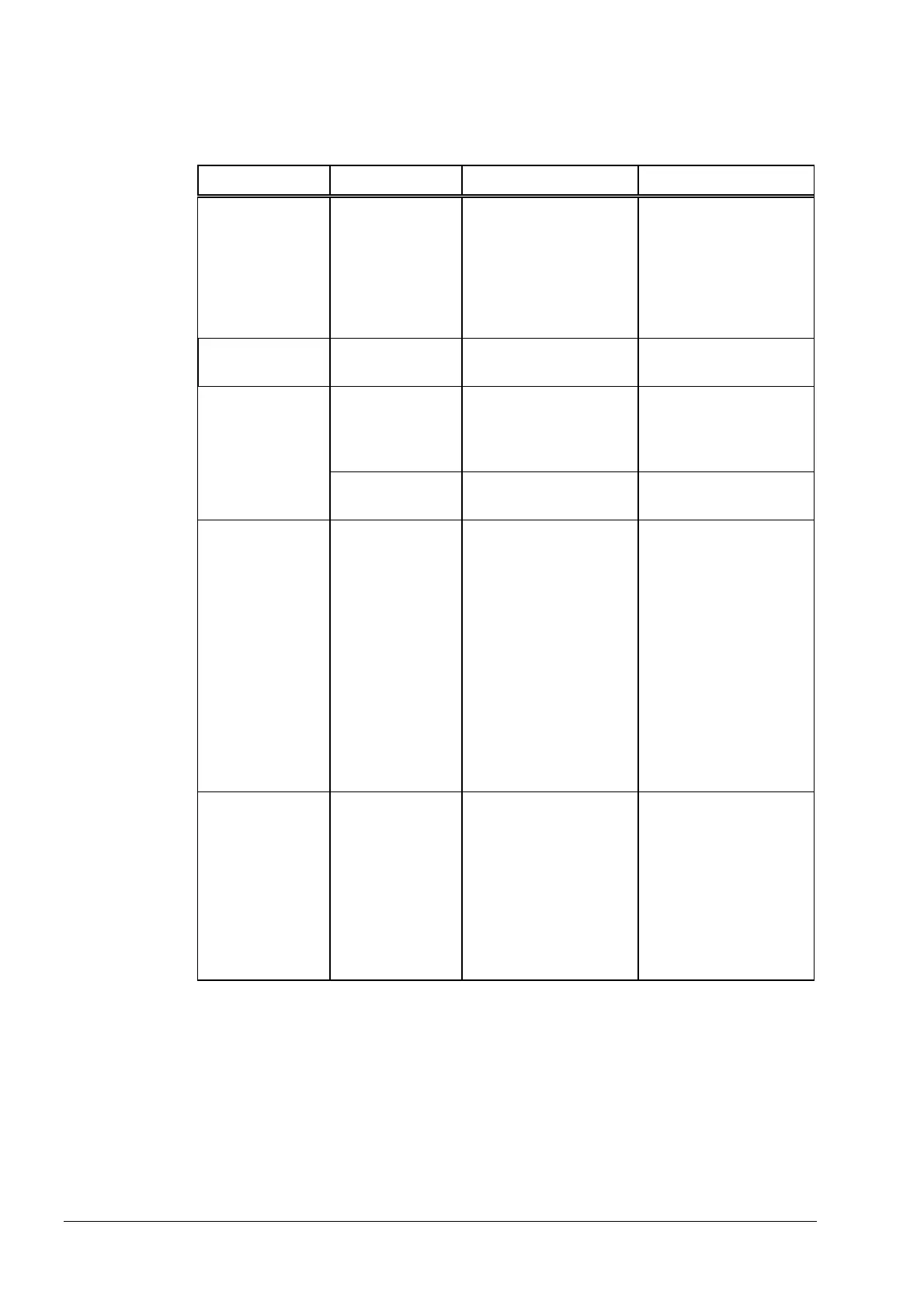

Other faults

The following table sets out explanations for eliminating faults which do not generate

fault messages on the monitor.

Fault Symptom Possible Cause Fault Locating Remedy

Battery mode not

possible; AC

mode function-

ing.

The battery is

missing, is not

connected or the

battery fuse is

faulty.

Check that the battery

has been fitted cor-

rectly and that the bat-

tery fuse is o.k.

Install and correctly

connect the battery

and/or change the fuse.

If the fault is repeated,

the splicer must be sent

to the service center for

examination.

Arc flickers or

hisses.

Electrodes dirty

or worn.

Clean or exchange

electrodes.

The fiber does

not melt during

fusion but buck-

les instead.

Fusion current

too low.

The splice point barely

lights up during splic-

ing.

Set correct fusion cur-

rent. Correct altitude

information or activate

altitude correction.

Fusion generator

is faulty.

The arc is not burning. Service center.

The fiber buckles

at the start of the

fusion process.

When automatic

fusion time con-

trol is used, a

more or less

usable splice is

obtained after a

long fusion time.

If the fusion time

is fixed, high

attenuation levels

are obtained.

The prefusion

time is too short

or the prefusion

current too low.

Correct the prefusion

parameter. You can

use the default parame-

ter as a basis.

Fusion process is

usually aborted

after less than

1 s (e.g. 0.6 s) if

automatic fusion

time control is

used, poor

splice, high at-

tenuation.

The minimum

fusion time is too

short. As a result

the automatic

fusion time con-

trol terminates

fusion before a

homogeneous

joint has formed.

The fiber shows irregu-

larities at the fusion

point when displayed

on the monitor. The

splice breaks easily

when removed.

Good results can be

achieved through

"Repeat fusion".

In most cases, you can

still 'rescue' unsuccess-

ful splices by fuse again

(see section 6, Fusion).

To prevent the faults

occurring in the first

place, increase the

minimum fusion time to

0.8 s - 1 s.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...