05.05 Function descriptions

SIEMENS AG 6RX1700-0AD76 9-29

SIMOREG DC Master Operating Instructions

Brief start-up guide for 6RA70 converters

G-SST2

RS485

G-SST3

RS485

Select peer-to-peer protocol P790 = 5 P800 = 5

Baud rate P793 = 1 to 13 corresponding to 300 to 187500

baud

P803 = 1 to 13 corresponding to 300 to 187500

baud

No. of process data (PZD No.)

(applies to Receive and Send)

P791 = 1 to 5 P801 = 1 to 5

PZD assignment for control word

and setpoints

(received process data)

All received process data are taken to connectors

and must be wired up as required

All received process data are taken to connectors

and must be wired up as required

No. of PKW No parameters can be transferred No parameters can be transferred

PZD assignment for actual

values

(transmitted process data)

Selection of transmitted values via P794

(indices .01 to .05)

Selection of transmitted values via P804

(indices .01 to .05)

Telegram failure time P797 = 0.000 to 65.000s P807 = 0.000 to 65.000s

Bus termination P795 = 0: Bus term. OFF

1: Bus term. ON

(depending on type of link)

P805 = 0: Bus term. OFF

1: Bus term. ON

(depending on type of link)

2-wire / 4-wire transmission

via RS485 interface

"4-wire" operation is automatically selected "4-wire" operation is automatically selected

Cable Terminal assignments, see Section 6.8 or Sheet

G173 in Section 8

Terminal assignments, see Section 6.8 or Sheet

G174 in Section 8

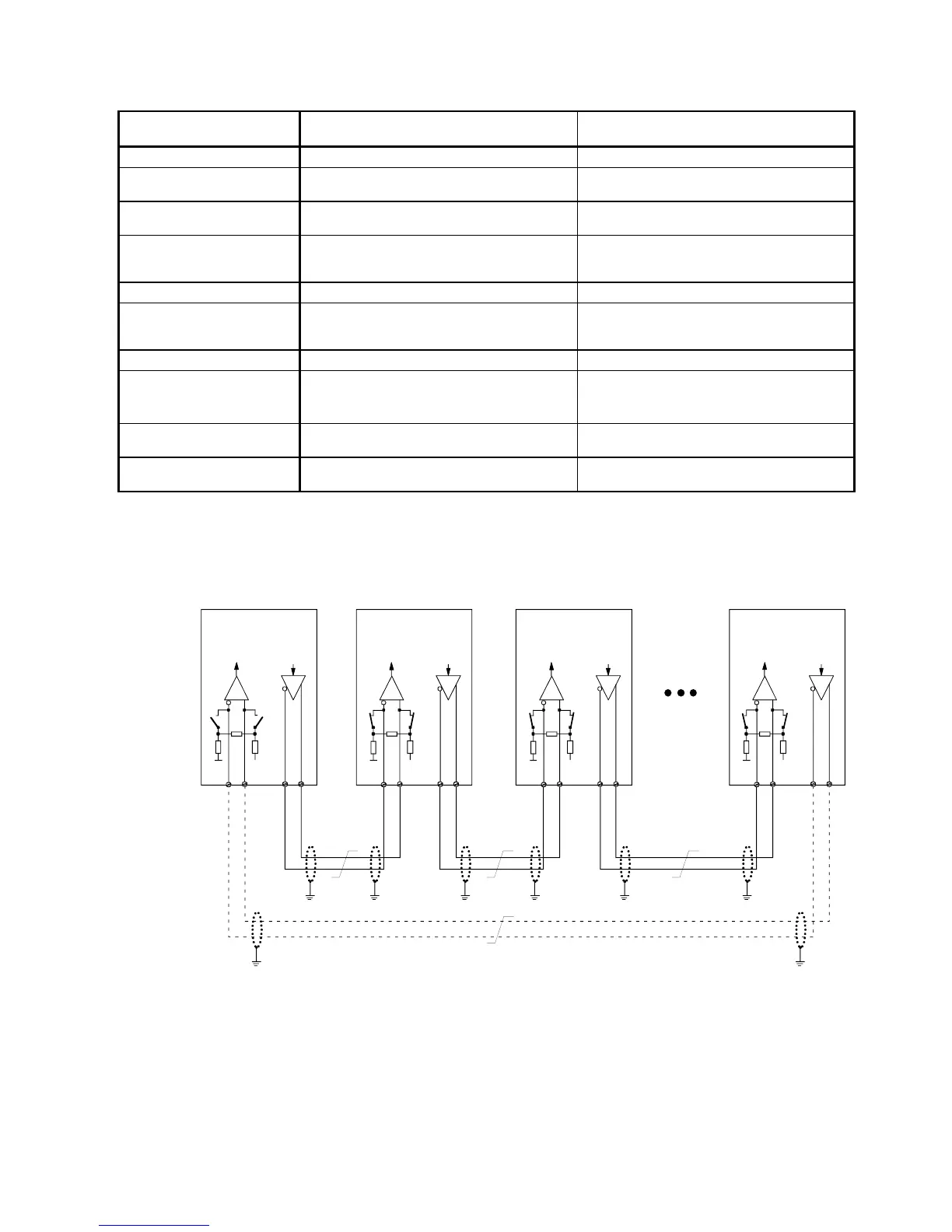

Examples of peer-to-peer links

Rx Tx

2)

+

56575859

--

++

6RA70

Rx Tx

+

56575859

--

++

6RA70

Rx Tx

+

56575859

--

++

6RA70

Rx Tx

+

56575859

--

++

6RA70

Peer link type "Series connection"

Each drive receives its own individual setpoint from the drive connected upstream (classic setpoint cascade)

1)

The interface cable shields must be connected directly on the converter with the lowest possible

impedance to converter or cubicle earth (e.g. via a clamp).

2)

Twisted cable, e.g. LIYCY 2x0.5 sqmm; with longer cables, an equipotential bonding conductor

must be used to ensure that the difference in frame potentials between nodes stays below 7 V.

3)

Optional data feedback loop via which drive 1 can monitor operation of the entire peer chain.

Drive 1

(Activate bus terminating

resistors when a data feed-

back loop is used)

Drive 2

(Bus terminating

resistors activated)

Drive 3

(Bus terminating

resistors activated)

Drive n

n=any number

(Bus terminating

resistors activated)

Data feedback loop 3)

Loading...

Loading...