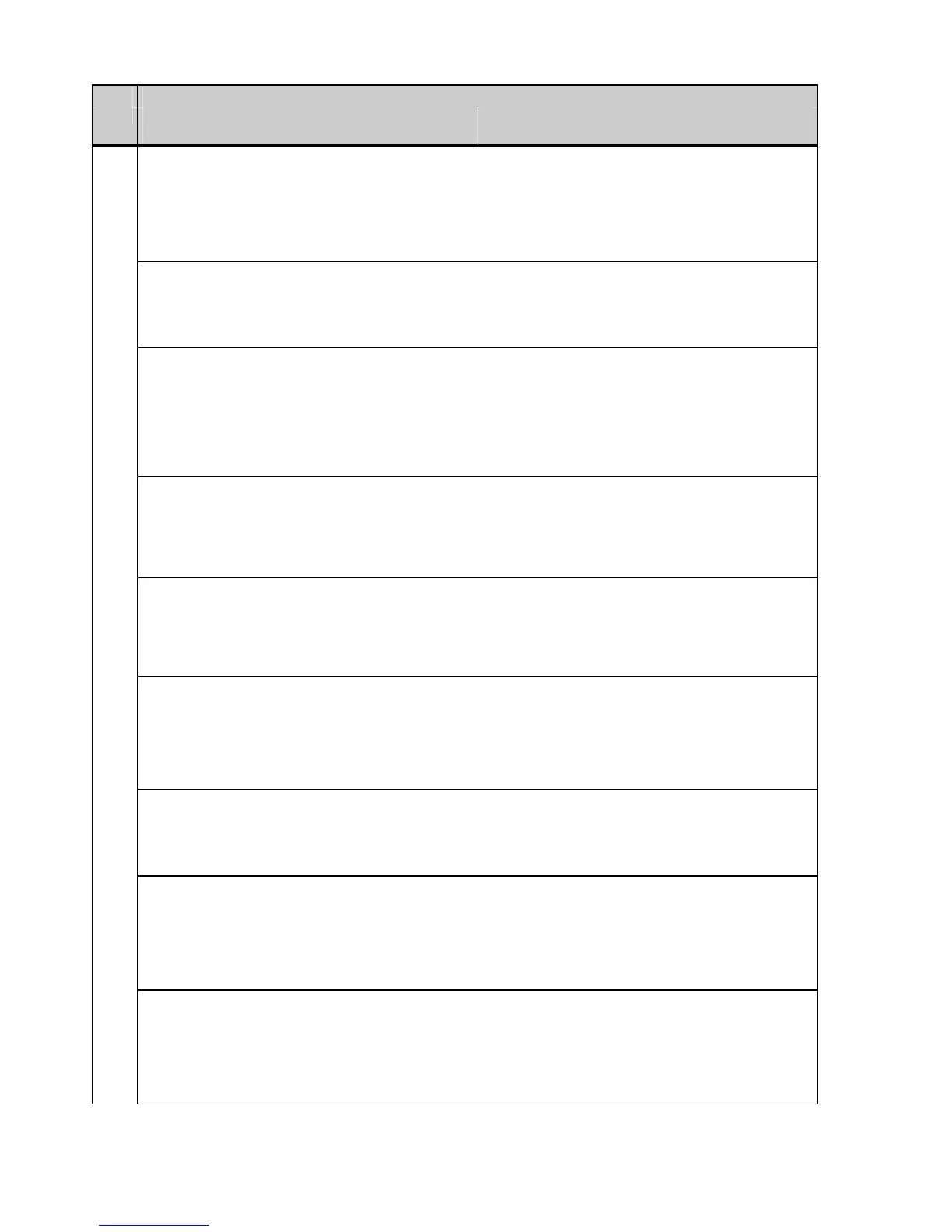

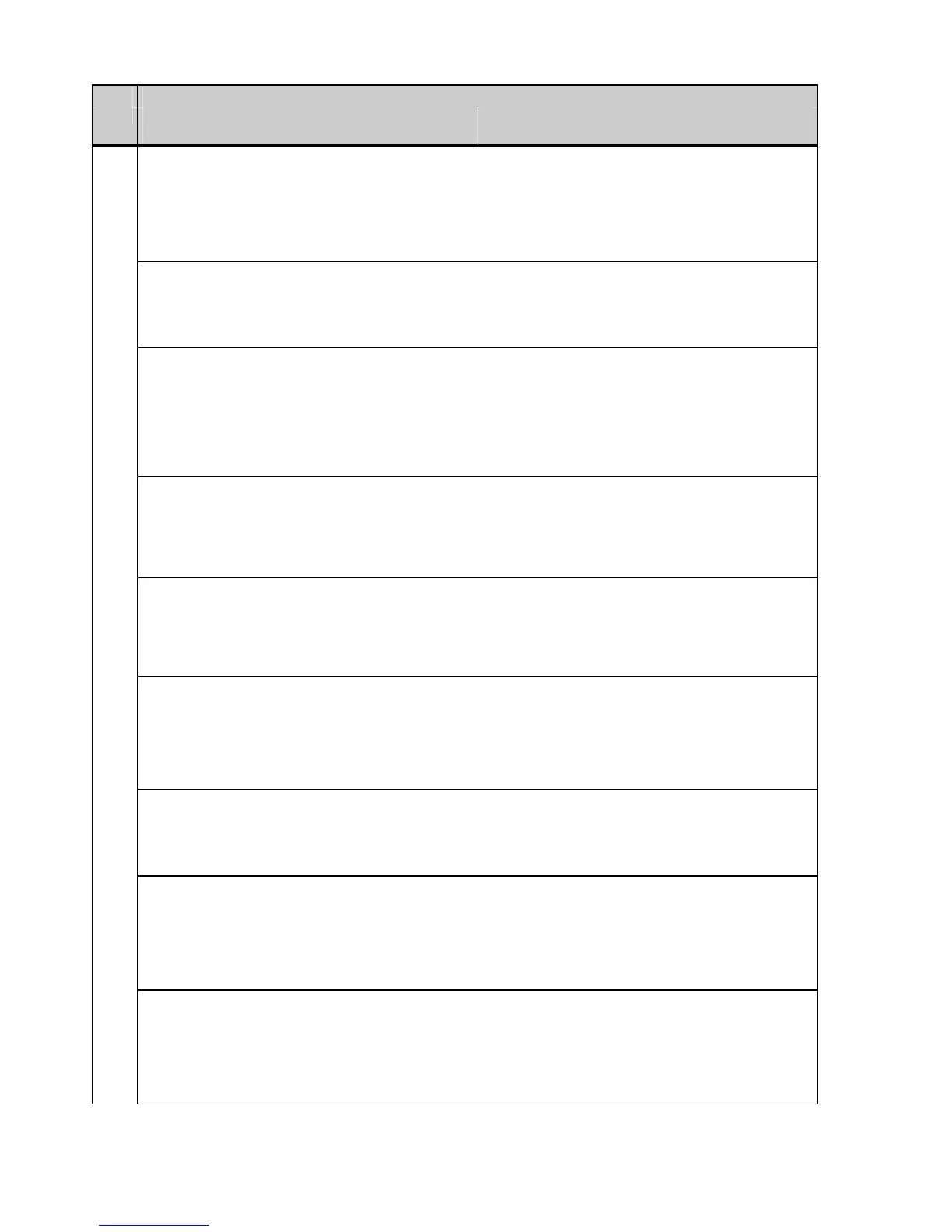

Faults / Alarms 05.05

10-14 SIEMENS AG 6RX1700-0AD76

SIMOREG DC Master Operating Instructions

Fault Description

No.

Cause as a function of fault value

(r047.001, r949.001 or r949.009 with acknowledged error)

Further information (r047.002 to r047.016)

4 The armature circuit inductance (P111) cannot be determined from the sampled values of the armature current and line

voltage of the armature current crest last generated

Possible cause:

•P100 (I

A,motor

) or r072.i002 (I

A,rated

) very much smaller than actual motor rated current of the armature

•L

A

>327.67mH (armature circuit inductance too large)

•P100 (I

A,motor

) very much smaller than r072.i002 (I

A,rated

)

•Armature circuit short-circuited

5 Offset adjustment of actual field current sensing is not possible

(value detected for P825 is outside permissible value range)

Possible cause:

• Fault in actual field current sensing circuit

(defective A7004 gating board or A7001 electronics board)

7 The field circuit resistance (P112) is indeterminable

(the actual field current does not reach the internally specified setpoint of 95% of P102 as a result of P112 variation)

Possible cause:

• R

A

>3276.7Ω

• Fault in actual field current sensing circuit (defective gating board or A7001 electronics board)

• The command “Inject standstill field” is applied

• P102 is set too high

• A thyristor in the field bridge is not firing

8 80% of rated EMF (K287=P101 – P100

*

P110) cannot be reached within 15s (or maximum of the three set acceleration

times)

Possible cause:

• Acceleration time (P303, P307, P311) is set too low

• P101 does not match the set maximum speed (U

A

at n

max

< P101) or setting for P102 is too low

• The command “Ramp-function generator enable”=0 or ”Ramp-function generator stop”=1

9 Field current control loop is not stable enough to record field characteristics

(30s after injection of internal field current setpoint, actual field current is deviating by more than (0.39% of P102 + 0.15 %

of r073.002) from the setpoint)

Possible cause:

• Field current controller or field current precontrol is not optimized or optimized badly (check P112, P253 to P256 or

execute a current controller optimization run (P051=25))

10 Field characteristic is not uniform

(i.e. in spite of field current setpoint reduction, the flux values of this measuring point calculated from EMF and actual speed

are rising)

Possible cause:

• High armature reaction and sharp load variations during recording of field characteristics

• Field current controller or field current precontrol is not optimized or optimized badly (check P112, P253 to P256 or

execute a current controller optimization run (P051=25))

11 A lower field current limit of ≥ 50% of P102 (I

F,motor

) is applied

(for this reason, it is not possible to plot a minimum of 9 field weakening measuring points)

Possible cause:

• P103 ≥ 50% of P102

Check P614 !

12 The drive has reached the positive torque limit even though the applied field current setpoint is still ≥ 50% of P102

(I

F,motor

)

Possible cause:

• Armature current is very “unsteady”, e.g. due to high speed controller P gain setting in P225 (on drive with high integral-

action time). In this case, setting a lower actual speed filtering value in P200 and execution of another speed controller

optimization run (P051=26) may help.

• Check torque limits

13 The drive has reached the positive armature current limit even through the applied field current setpoint is still ≥ 50% of

P102 (I

F,motor

)

Possible cause:

• Armature current is very “unsteady”, e.g. due to high speed controller P gain setting in P225 (on drive with high integral-

action time). In this case, setting a lower actual speed filtering value in P200 and execution of another speed controller

optimization run (P051=26) may help

• Check armature current limits

Loading...

Loading...