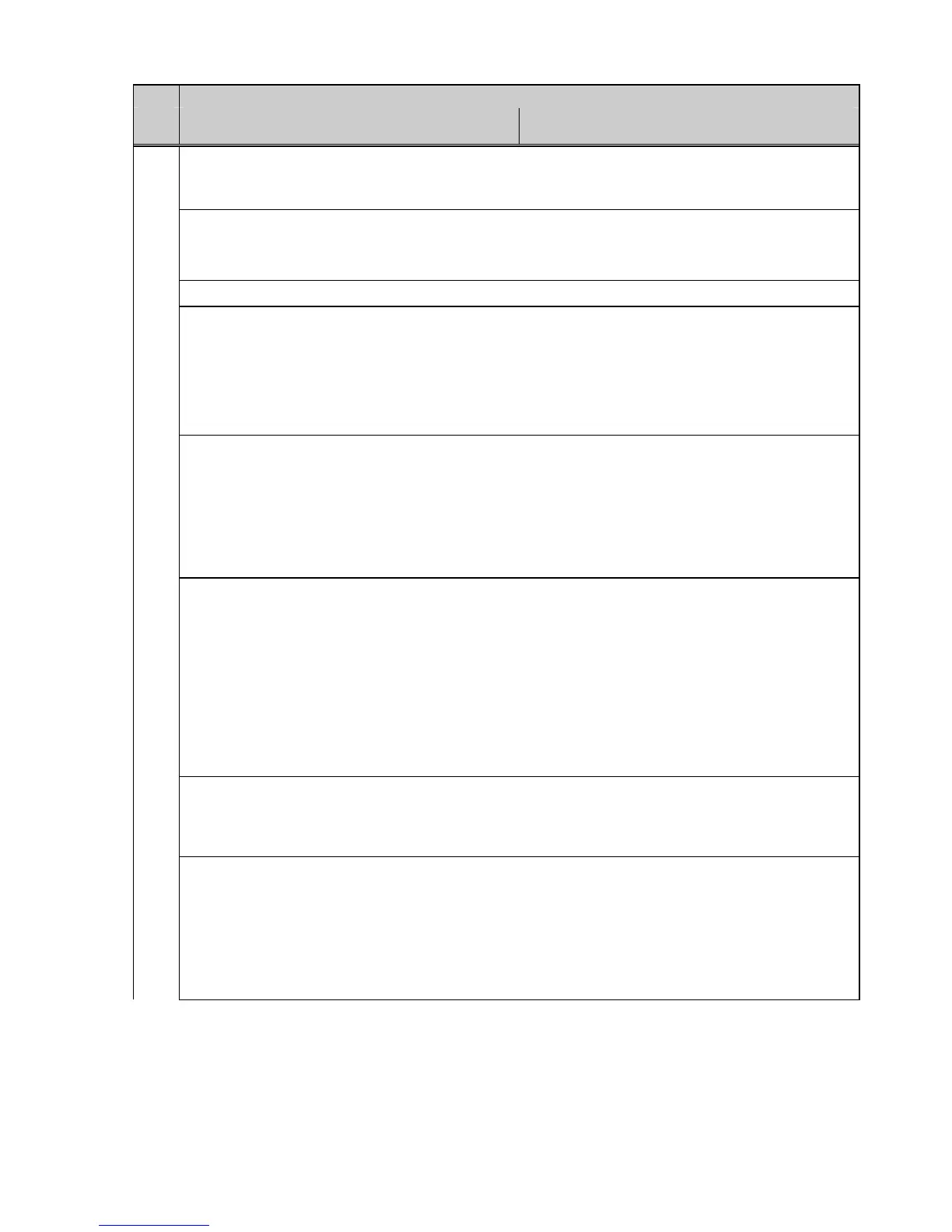

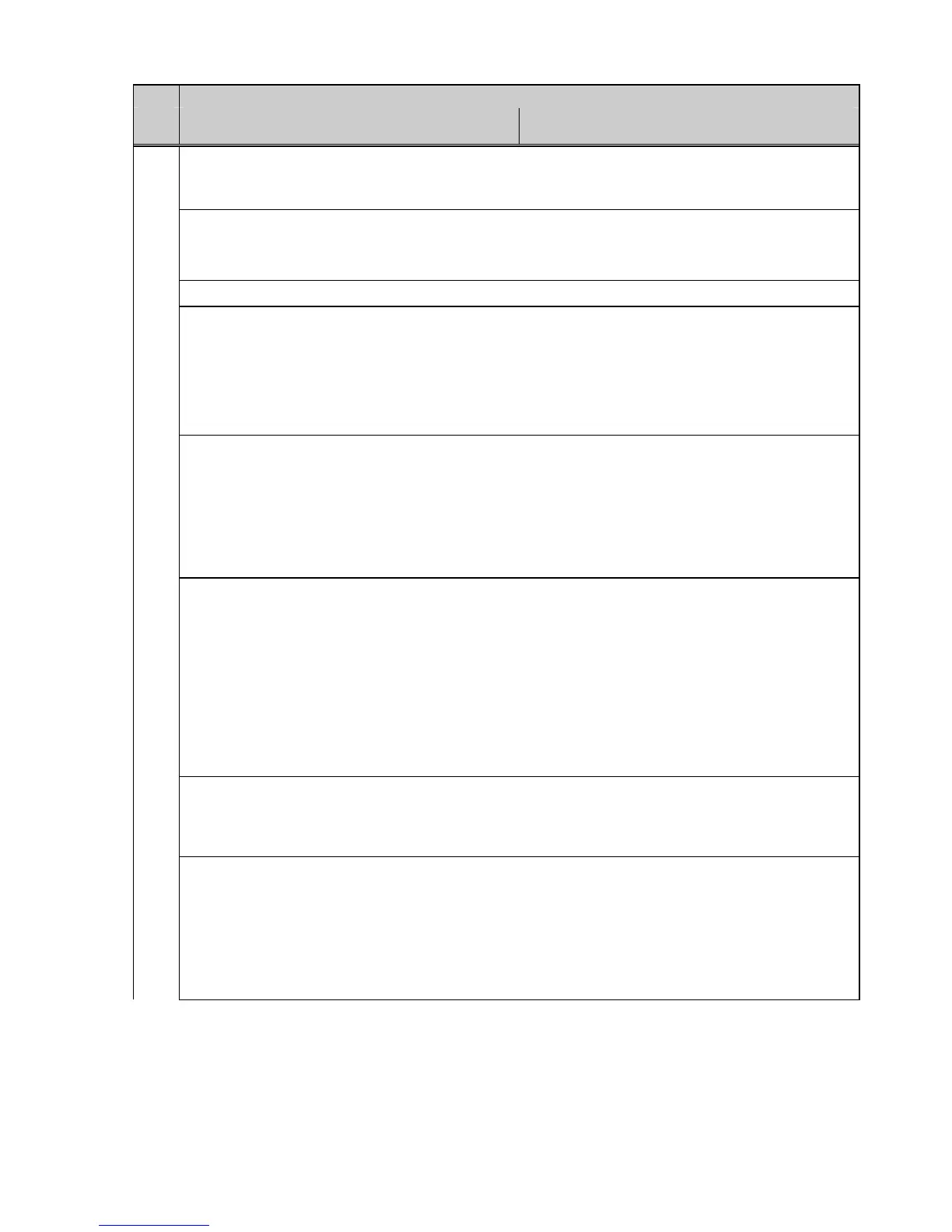

05.05 Faults / Alarms

SIEMENS AG 6RX1700-0AD76 10-15

SIMOREG DC Master Operating Instructions

Fault Description

No.

Cause as a function of fault value

(r047.001, r949.001 or r949.009 with acknowledged error)

Further information (r047.002 to r047.016)

14 The speed has changed by more than 12.5% at a constant speed setpoint even through the applied field current setpoint is

still ≥ 50% of P102 (I

F,motor

)

Possible cause: as for fault value 12

15 The EMF setpoint is too small to plot a field characteristic

EMF

set

= U

A

– I

A,motor

*

R

A

= P101 – P100

*

P110 < 10% of 1.35

*

P078.i001

(e.g. P078.i001 = 400 V . . . minimum EMF

set

= 54 V)

16 Field weakening operation is not allowed in operation without a tachometer (P083=3)

17 The field current controller cannot be optimized because the field circuit time constant cannot be determined (actual field

current does not decay after switch-off to below 0.95*initial value within approximately 1s or to below 0.8 * 0.95*initial

values within approximately 2 s)

Possible cause:

• Setting in P103 is too high

• Field circuit inductance is too high

• Fault in actual field current sensing circuit (gating board or A7001 electronics board defective)

• Ratio r073.02 / P102 is too high (change P076.02 if necessary)

18 Field weakening range is too wide, i.e. during power-up (at full field) to a speed setpoint of +10% n

max

, the |EMK| is > 77%

of setpoint EMF (P101 – P100

*

P110)

Possible cause:

• Maximum speed setting is incorrect

• Pulse encoder parameters are incorrect (P140 to P143)

• Parameters for tachometer adaptation are incorrect (P741)

• Setpoint EMF is not correct (P101, P100, P110)

• An excessively high load torque (in positive or negative direction, e.g. a suspended load) causes the drive to rotate, one

of the armature current or torque limits may be parameterized too low

19 A steady-state actual speed of +10%, +20%, +30% . . . or +100% of the maximum speed cannot be reached within 3

minutes (or maximum value of the three set acceleration times) in speed-controlled operation (the speed setpoint/actual

value difference averaged over 90 firing cycles must equal <0.1% n

max

for a specific time period)

Possible cause:

• Acceleration time is set too low (P303, P307, P311)

• Drive is blocked

• An excessively high load torque (in positive or negative direction, e.g. a suspended load) causes the drive to rotate, one

of the armature current or torque limits may be parameterized too low

• Poor speed controller setting (P225, P226, P228) or speed controller is parameterized as pure P controller or with

droop

• A band elimination filter (P201, P202 or P203, P204) is active

• Command “Ramp-function generator enable” =0 or ”Ramp-function generator STOP” =1 is applied

• “Field weakening operation” (P081 = 1) is not parameterized

20 Current limit is too low

(With speed controller optimization run: Less than 30% or 45% of P100 (I

A,motor

) + the armature current required for zero

speed,

With optimization run for friction moment and moment of inertia compensation: Less than 20% of P100 (I

A, motor

) + the

armature current required for a steady-state speed corresponding to 10% of maximum speed)

21 Field weakening range is too wide (n

act

< +7% n

max

produces |EMF| > 54% setpoint EMF)

(setpoint EMF= K289= P101 – P100

*

P110)

Possible cause:

• Maximum speed setting is incorrect

• Pulse encoder parameters are incorrect (P140 to P143)

• Parameters for tachometer adaptation are incorrect (P741)

• Setpoint EMF is not correct (P101, P100, P110)

• Caution:

Even a high absolute negative actual speed value can produce an | EMF | of > 54% setpoint EMF

Loading...

Loading...