7

Commissioning

SIMPRO-100

106 PRIM-2400C

7.3.5 Motor Thermal Element

Accuracy

Note: This test outlines steps to verify

performance of any of the GENERIC

thermal curves. When using the RATING

or USER thermal element setting

methods, the steps are similar, but the

expected operating times will be different,

depending on the settings you use.

1. Connect the current sources to the IA, IB, and

IC current inputs (5 A or 1 A, as indicated by

the ITAP setting).

2. Using the front-panel Set Relay\Relay

Elements\Thermal Model Elements function

or serial port SHOW command, note the

PHROT, FLA, and CURVE settings. Set the

Service Factor setting, SF equal to 1.15.

Note: Changing settings requires that you

enter the Access Level 2 password.

The factory password is 100.

3. Set the current source phase angles to apply

balanced three-phase currents. Refer to

Figure 7.1, page 100 for the correct angles,

which depend on the PHROT setting.

4. Reset the motor thermal element using the

front-panel Reset Thermal Model function.

Note: This function requires that you enter

the Access Level 2 password. The

factory password is 100.

Set the current sources to apply the test current

shown in Table 7.6, then turn on the current

sources together. Refer back to Table 7.6 to

determine the expected element operating time.

For instance, when the setting CURVE is equal

to 4, the thermal element should trip in

4 • 10 = 40 seconds when applied three-phase

current equals three times the motor full load

current setting, FLA. Use the front-panel Meter

Values\Thermal & RTD Data function to view the

estimated Time to Thermal Trip during each test.

Note: Reset the motor thermal model before

each test run or the element will trip faster

than expected.

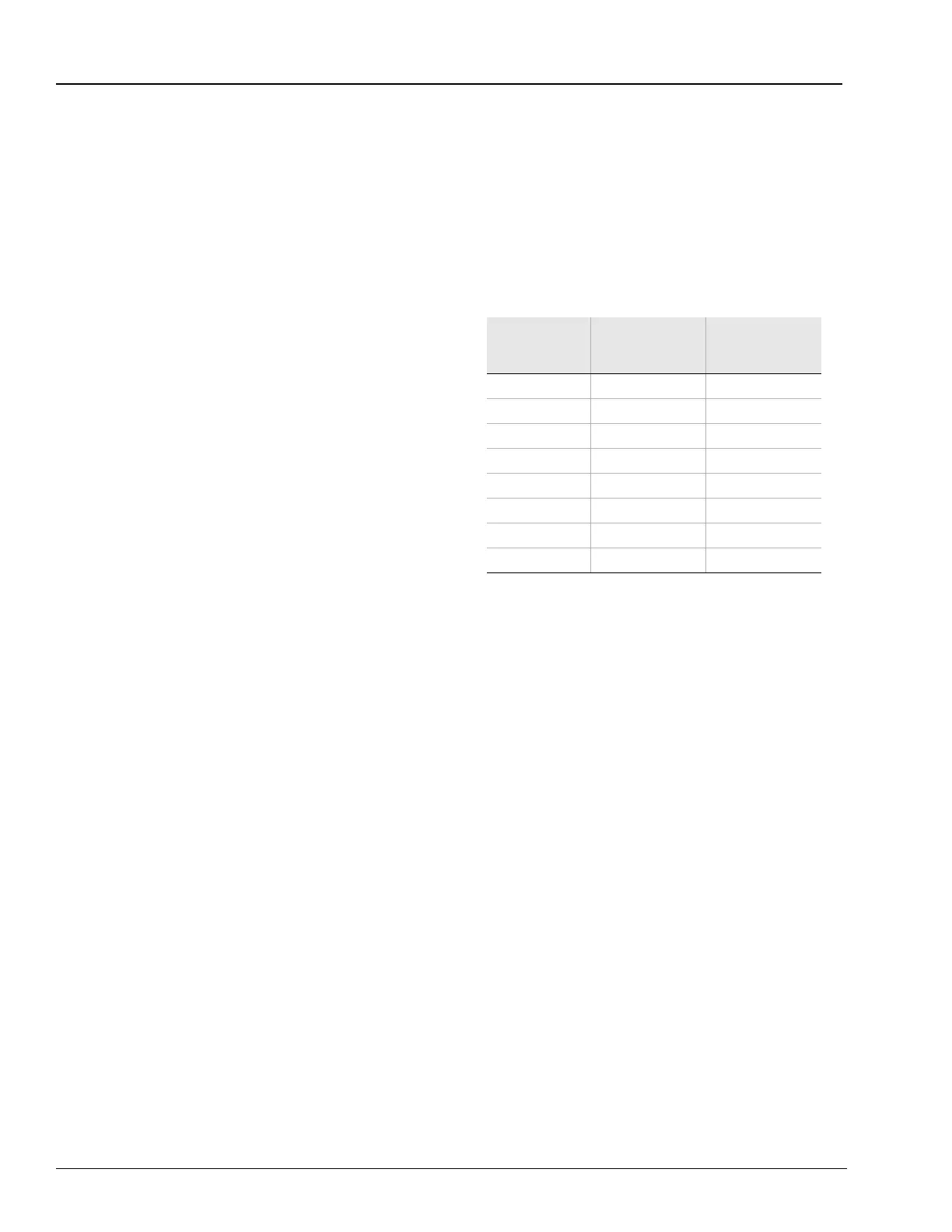

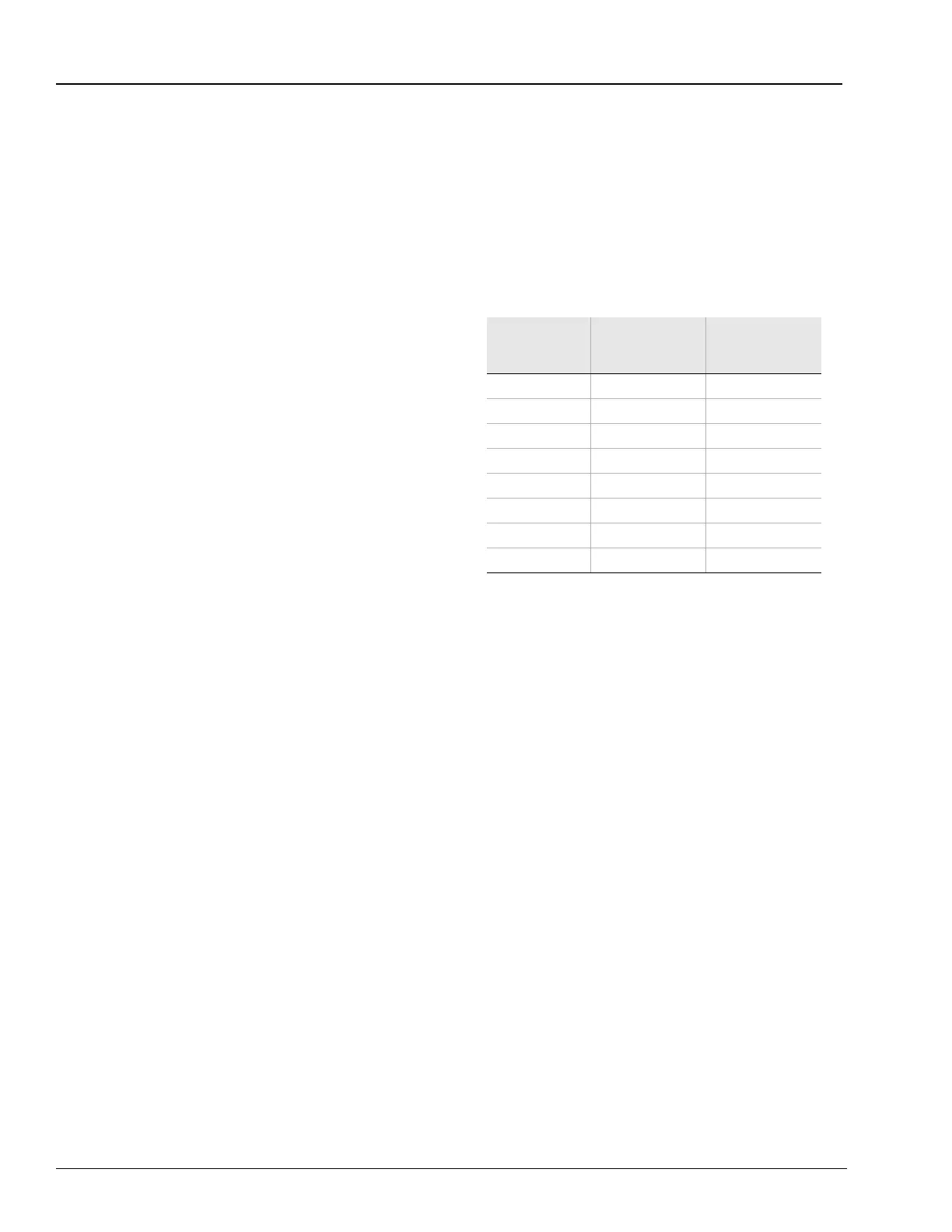

Table 7.6 Thermal Element Expected Trip Times

7.3.6 Analog Output Accuracy

1. Connect a dc milliammeter in series with the

analog output terminals (B01, B02). Connect

a PC to the relay front-panel serial port using

an appropriate serial cable. Using the

SIMPRO-PC software terminal function or

other terminal emulation software, establish

communications with the relay at Access

Level 2 (see Chapter 6, page 85 for details).

2. Use the Access Level 2 ANALOG command

to temporarily control the analog output. Refer

to Table 7.7 on page 107. Using the

milliammeter reading, verify that the analog

output is correct for each level.

Applied

Current

(A secondary)

Expected Time

to Trip

(s)

Measured Time

to Trip

(s)

1.2 • FLA CURVE • 145.7

1.5 • FLA CURVE • 51.5

2.0 • FLA CURVE • 23.3

3.0 • FLA CURVE • 10.0

4.0 • FLA CURVE • 5.63

5.0 • FLA CURVE • 3.60

6.0 • FLA CURVE • 2.50

7.0 • FLA CURVE • 1.84

Loading...

Loading...