SIMPRO-100

Settings Calculation

4

PRIM-2400C 53

4.4.1.4 Thermal Capacity Alarm Setting

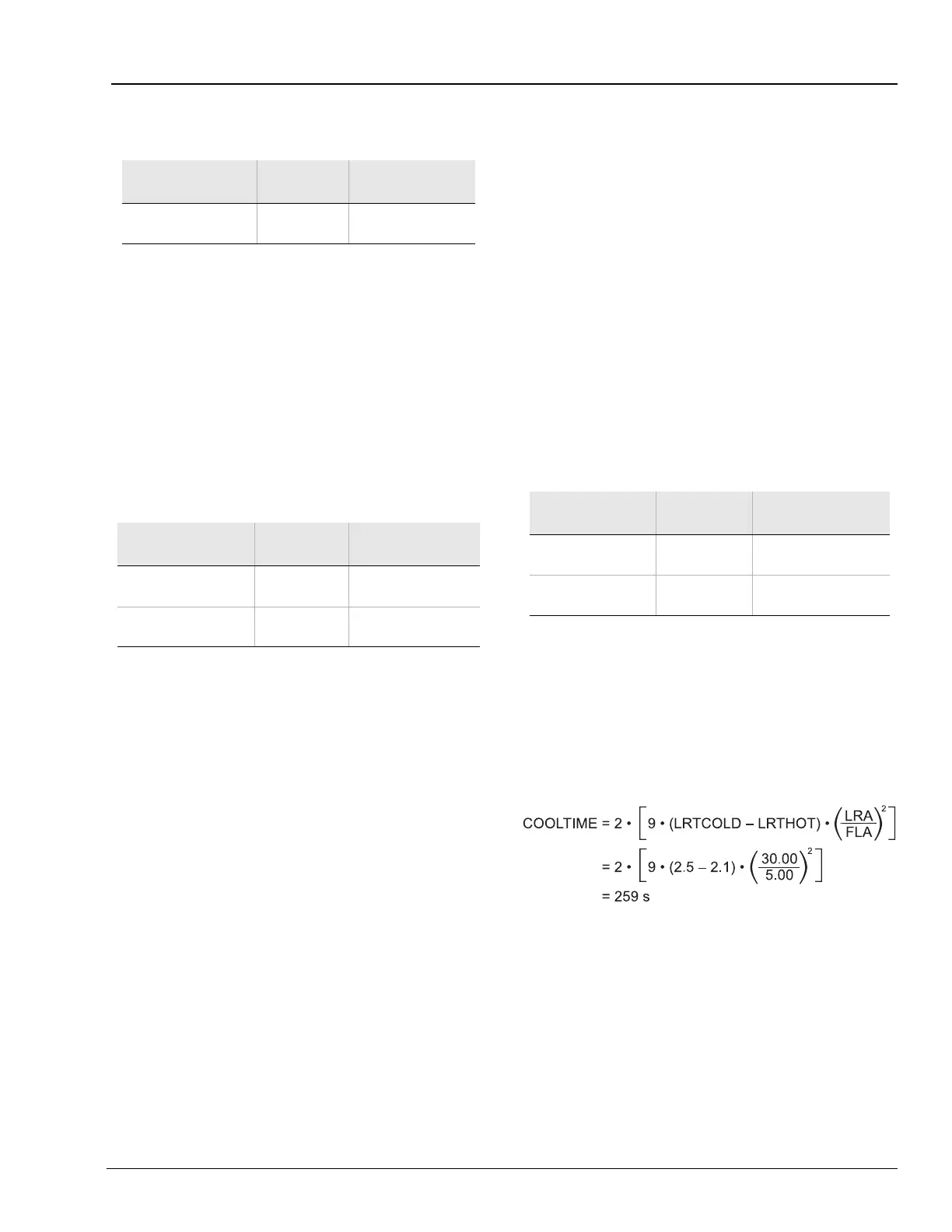

Table 4.12 Thermal Capacity Alarm Setting

For all thermal element settings methods, the

relay provides a thermal alarm. When the motor

thermal capacity used exceeds the Thermal

Capacity Alarm Pickup (TCAPU), the relay issues

an alarm. The early alarm may allow you to

correct the load problem before a thermal trip

occurs.

4.4.1.5 Thermal Capacity to Start

Settings

Table 4.13 Thermal Capacity to Start Settings

The motor tripping and starting functions include

supervision to help prevent a thermal trip on a

normal start. The relay prevents motor starting

until the thermal element has enough available

thermal capacity to allow a motor start without

tripping. The available thermal capacity required

to start is (100% – 10% – TCSTART), where the

Thermal Capacity Used To Start (TCSTART)

setting or the relay can learn a value.

When you use the Use Learned Starting Thermal

Capacity function (TCLRNEN = Y), the relay

records the thermal capacity used during the past

five starts and uses it in the thermal model in

place of the Thermal Capacity Used to Start

setting. The relay adds 10% to the largest of the

last five starting thermal capacities and requires

that the motor thermal model cool enough to

permit that start.

Example: Learned Starting Thermal Capacity

Calculation

Over the past five starts, a motor has used

24%, 27%, 22%, 25%, and 26% of thermal

capacity. The largest thermal capacity to

start is 27%. The relay requires that the

present thermal capacity drop below 63%

(100% – 37%) before a new start is

allowed.

You can view the present learned thermal

capacity to start using the serial port MOTOR

command or the front-panel Motor

Statistics\Average and Peak Data Function (see

Figure 5.29, page 82.

4.4.1.6 Motor Cooling Time Settings

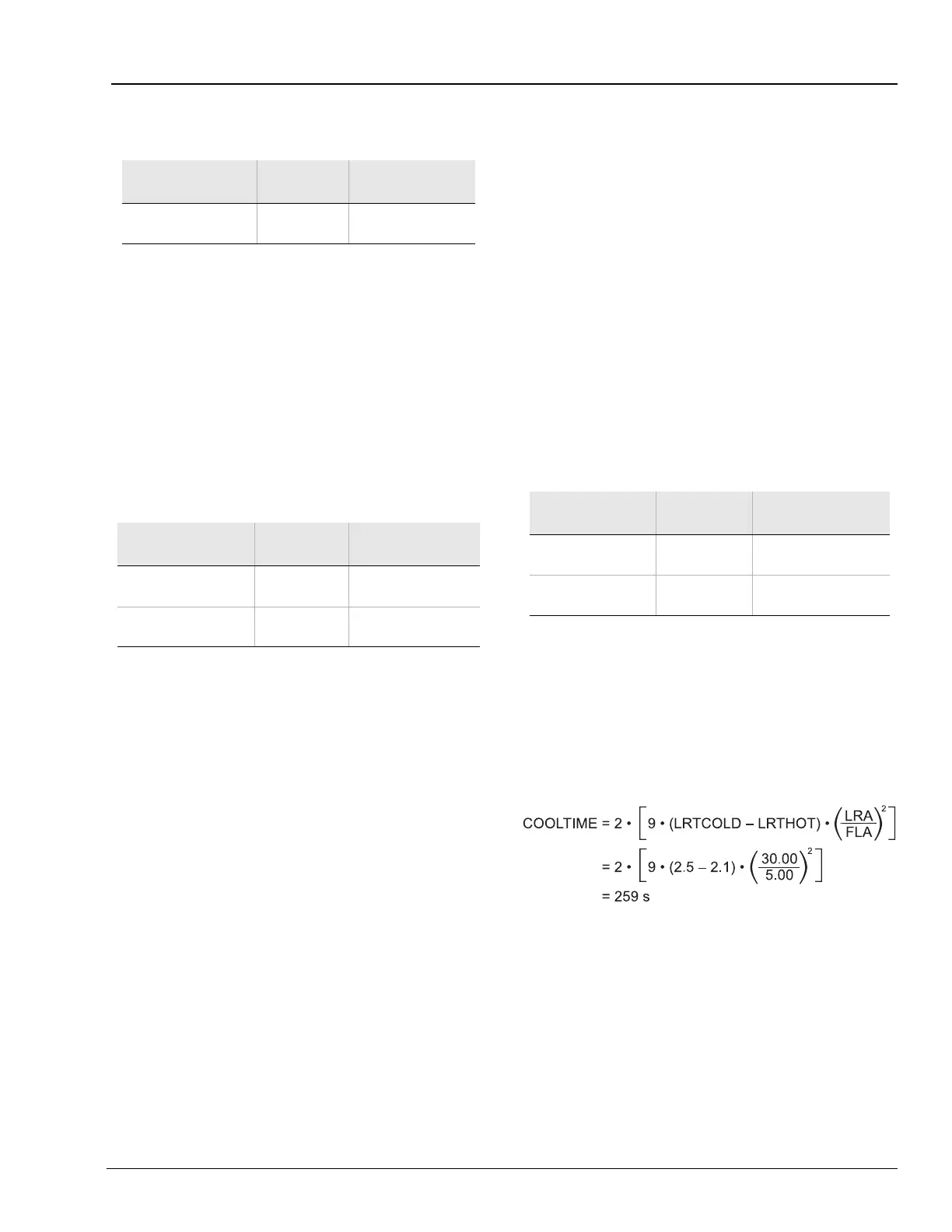

Table 4.14 Motor Cooling Time Settings

A stopped motor may take longer to cool than a

running motor due to reduced airflow or loss of

forced coolant. The factory default settings

assume that the motor stopped cooling time is

twice the motor running cooling time. Based on

the setting names, the equation is:

Equation 4.2

You can take similar steps to calculate the

COOLTIME setting for your application.

Motor running and stopped cooling times or time

constants may be provided by the motor

manufacturer. If a time constant is provided,

multiply that value by 3 to calculate the Motor

Stopped Cooling Time (COOLTIME) setting.

Setting Prompt

Setting

Range

Setting Name =

Factory Default

Thermal Capacity

Alarm Pickup

50% – 100% TCAPU = 90

Setting Prompt

Setting

Range

Setting Name =

Factory Default

Thermal Capacity

Used to Start

20% – 100% TCSTART = 85

Use Learned Starting

Thermal Capacity

Y, N TCLRNEN = Y

Setting Prompt

Setting

Range

Setting Name =

Factory Default

Motor Stopped

Cooling Time

180 – 72000 s COOLTIME = 259

Use Learned

Cooling Time

Y, N COOLEN = Y

Loading...

Loading...