4

Settings Calculation

SIMPRO-100

46 PRIM-2400C

Example: Thermal Element Rating Method

Setting

A 4160 V, 600 HP motor is to be protected

using the SIMPRO-100 Relay Thermal

Element Rating Method. The motor data

sheet includes the following information.

Rated Horsepower (HP) = 600 HP

Rated Voltage (V) = 4160 V

Rated Full Load Current (A) = 62.1 A

Rated Locked Rotor Amps (A) = 382.5 A

Safe Stall Time at 100% Volts

Cold = 21 seconds

Hot = 16 seconds

Service Factor = 1.2

Phase current transformers having 80:5

ratios are selected for the application. The

SIMPRO-100 Relay settings for the

application are calculated as shown below.

Current Transformer Ratio (CTR) =

80/5 = 16

CT Secondary Rating (ITAP) = 5

Full Load Amps (FLA) = 62.1/16 =

3.88 A secondary

Service Factory (SF) = 1.2

Locked Rotor Amps (LRA) = 382.5/16 =

23.9 A secondary

Hot Locked Rotor Time (LRTHOT) =

16 seconds

Cold Locked Rotor Time (LRTCOLD) =

21 seconds

The Locked Rotor Trip Time Dial setting reduces

or extends the allowed accelerating time under

locked rotor conditions. You can always safely set

this value equal to 1.00. If you know that the

driven load will always accelerate in less than the

rated locked rotor time, you may wish to use a

Locked Rotor Trip Time Dial less than 1.00 to

provide a faster trip in locked rotor conditions. Do

not set the Locked Rotor Trip Time Dial setting

greater than 1.00, except in an emergency to

allow a start with a longer than normal

accelerating time.

Example: Locked Rotor Trip Time Dial

Setting Calculation

In a particular application, a motor with a

10 second hot locked rotor time always

starts in 5 seconds.

Setting the Locked Rotor Trip Time Dial

setting equal to 0.75 causes the relay to trip

in 7.5 seconds under locked rotor

conditions. This setting allows ample time

for the motor to start, but does not subject

the motor to the full 10 seconds of locked

rotor current if a locked rotor start attempt

takes place.

Continue calculating the balance of thermal

element settings with Section 4.4.1.4, page 53.

4.4.1.2 Thermal Element GENERIC

Setting Method

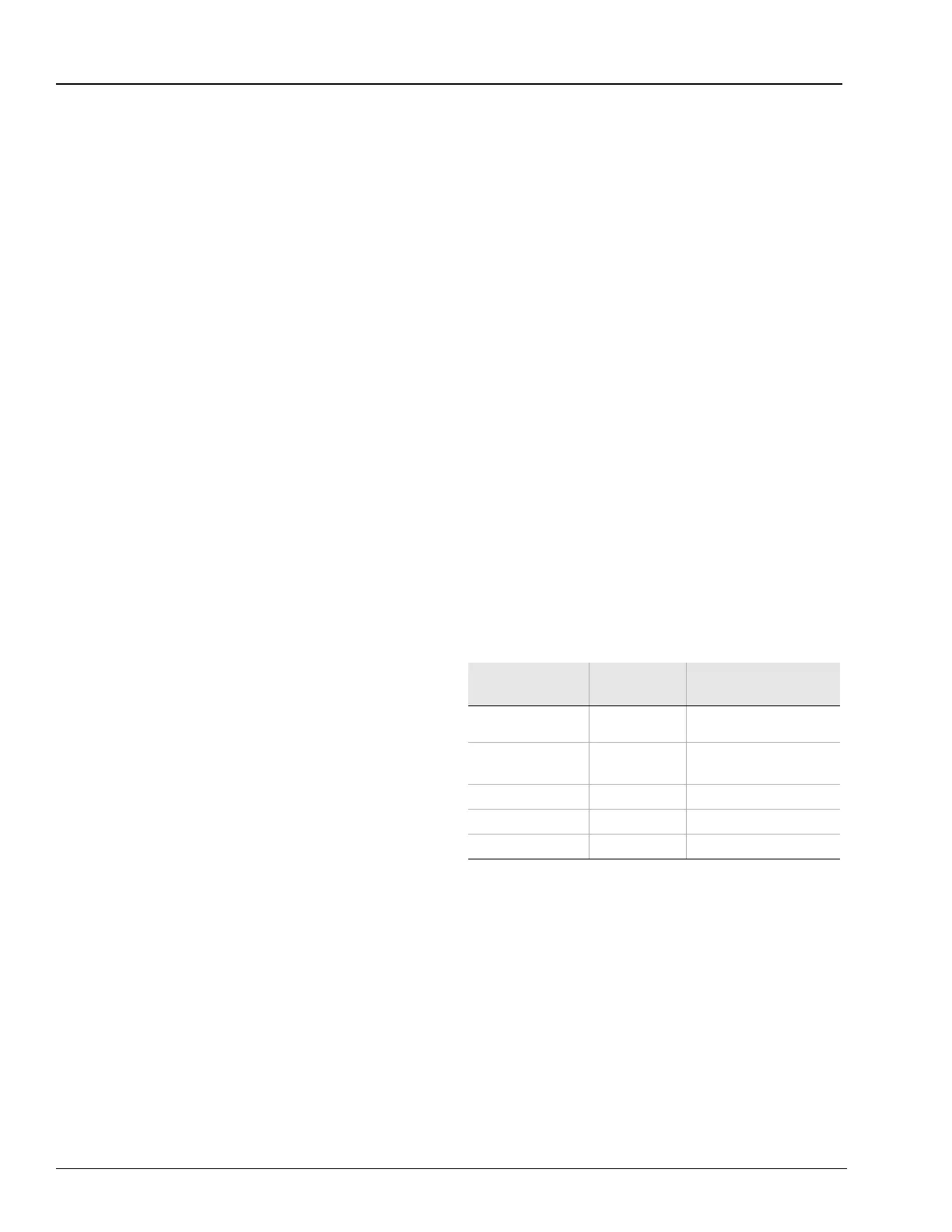

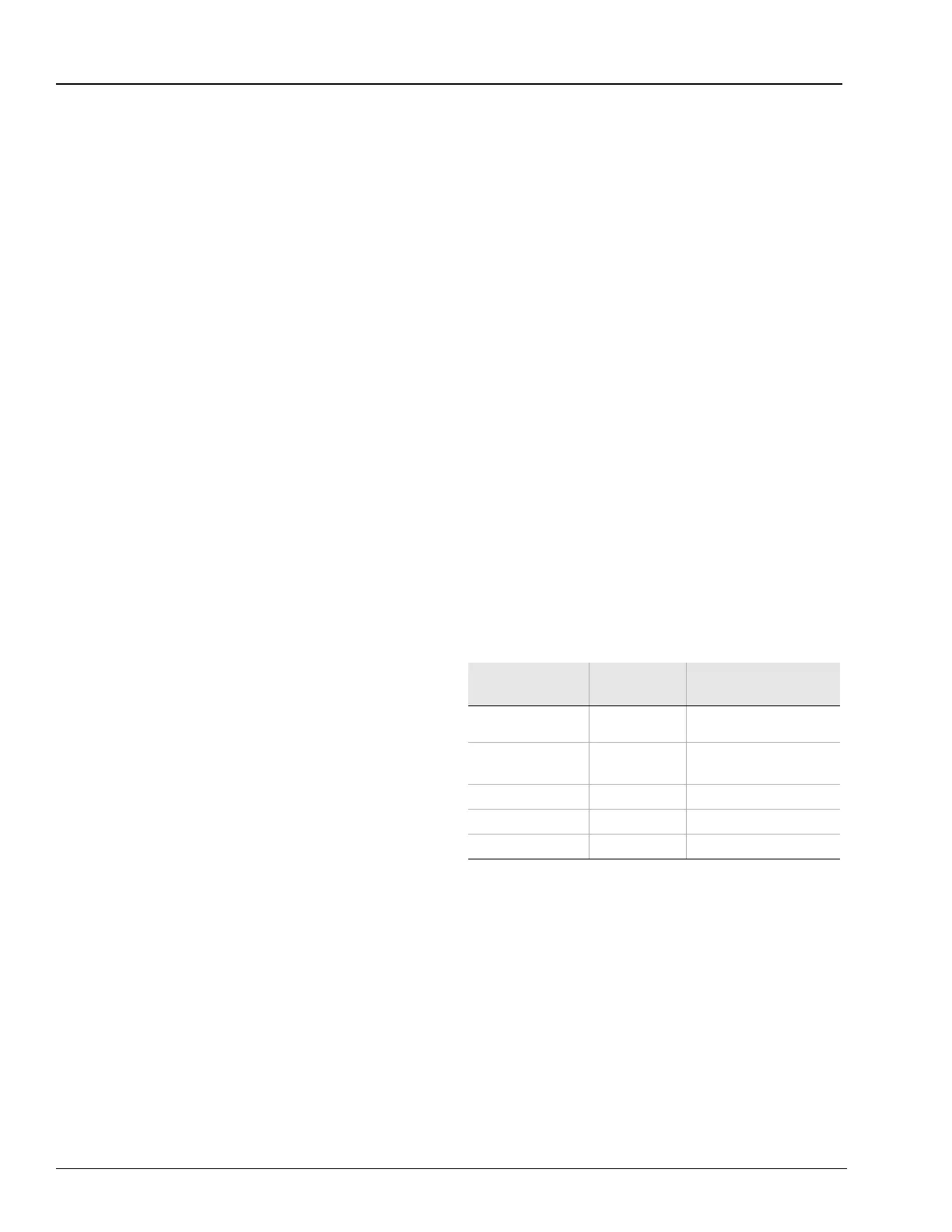

Table 4.7 Thermal Element Configuration Settings,

Setting Method = GENERIC

For simple, yet thorough motor protection, you

may elect to use one of the 45 available standard

motor overload/locked rotor curves. Set the motor

rated Full Load Amps and Service Factor, then

select the desired curve from Figure 4.2,

page 48. Be sure that the standard curve you

select trips in a time less than or equal to the

motor rated locked rotor time at locked rotor

current. Each increase in the curve number yields

a 2.5 second increase in the curve thermal limit

Setting Prompt

Setting

Range

Setting Name =

Example Setting

Setting Method

Rating,

Generic, User

SETMETH = GENERIC

Full Load Amps

2.50 – 8.00 A

ITAP = 5 A

FLA = 5.00

0.50 – 1.60 A FLA = 1.00

Service Factor 1.00 – 1.50 SF = 1.15

Curve Number 1 – 45 CURVE = 1

Loading...

Loading...