SIMPRO-100

Settings Calculation

4

PRIM-2400C 51

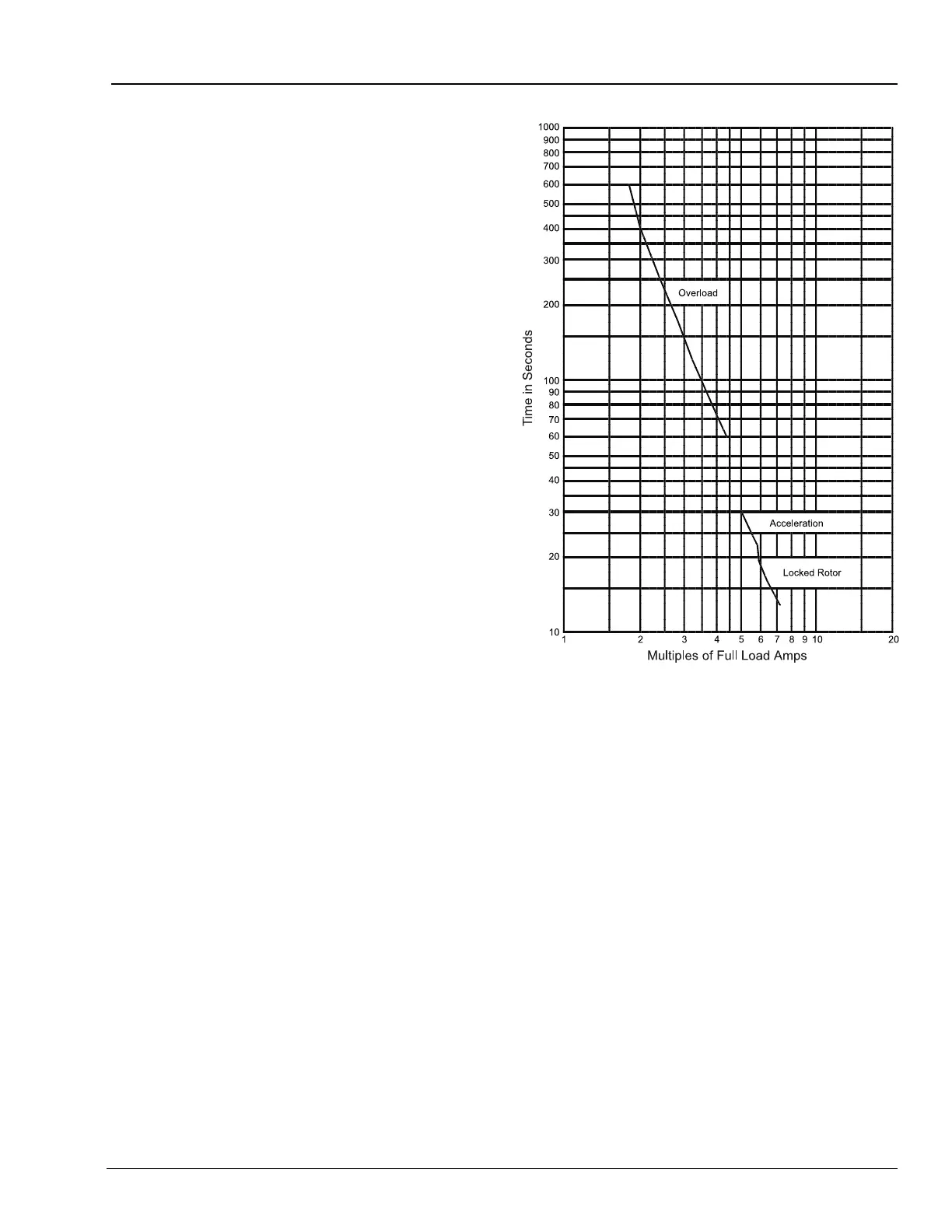

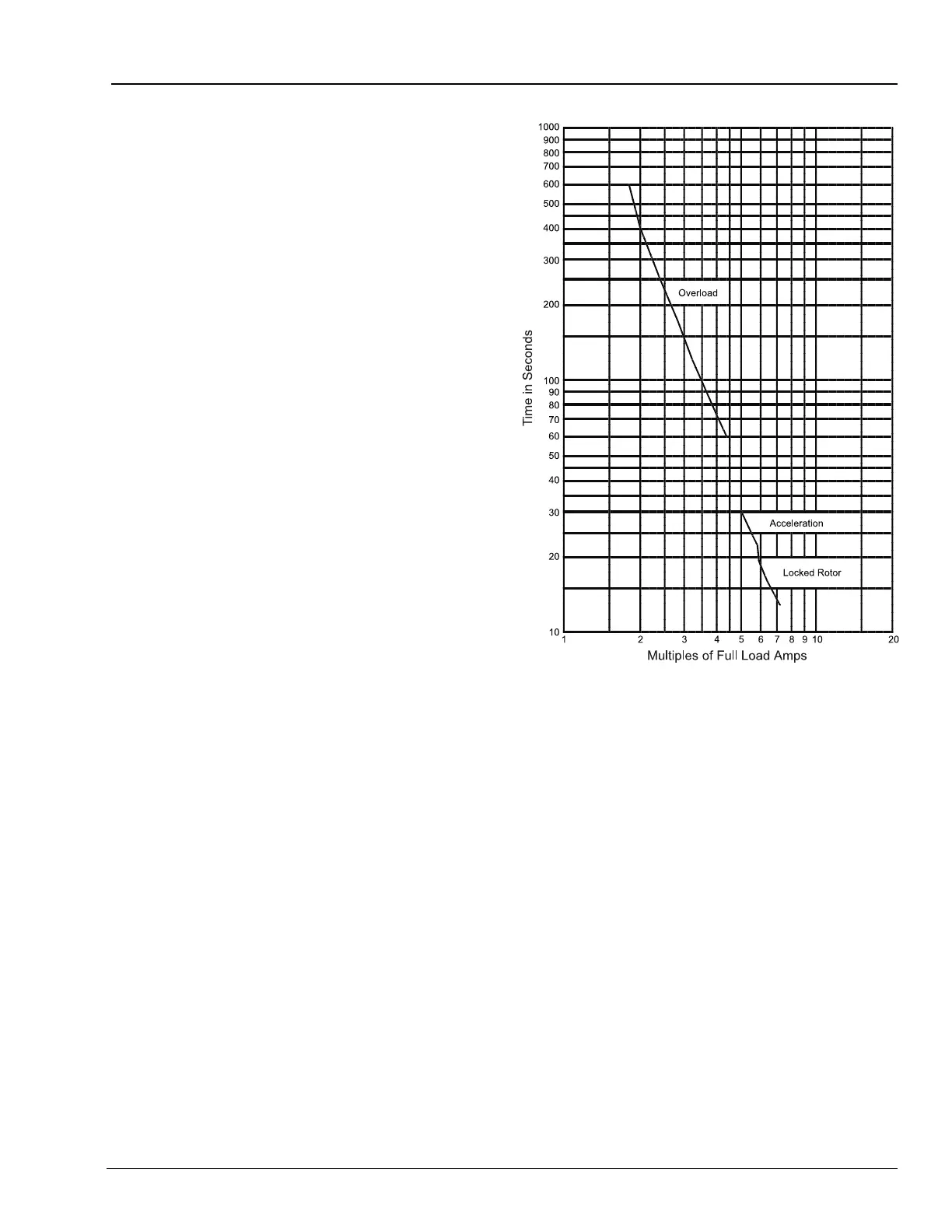

If you wish to emulate a manufacturer’s specified

thermal limit curve, you may enter additional time

points along the curve. If you do not wish to enter

a time for a point, enter NP. The relay

automatically creates a smooth thermal limit

curve between the entered time points.

Normally, you would use this method only if the

motor thermal limit curve includes a discontinuity

between the stator limit curve and the locked

rotor limit curve, as shown in Figure 4.3.

Example: Thermal Element User Method

Setting

A 4000 V, 3000 HP motor is to be protected

using the SIMPRO-100 Relay Thermal

Element User Method. The motor data

sheet includes the following information:

Rated Horsepower (HP) = 3000 HP

Rated Voltage (V) = 4000 V

Rated Full Load Current (A) = 366 A

Rated Locked Rotor Amps (A) = 2380 A

Safe Stall Time at 100% Volts

Cold = 16 seconds

Hot = 12 seconds

Service Factor = 1.25

The data sheet also includes the Thermal

Limit Curve shown in Figure 4.3.

Figure 4.3 3000 HP Example Motor Cold Thermal

Limit Curve

The discontinuities in the thermal limit curve

between the Overload, Acceleration, and Locked

Rotor curve sections make this motor ideal for

protection using a purpose-built thermal limit

curve. The User setting method provides the

facility to protect this motor.

Loading...

Loading...