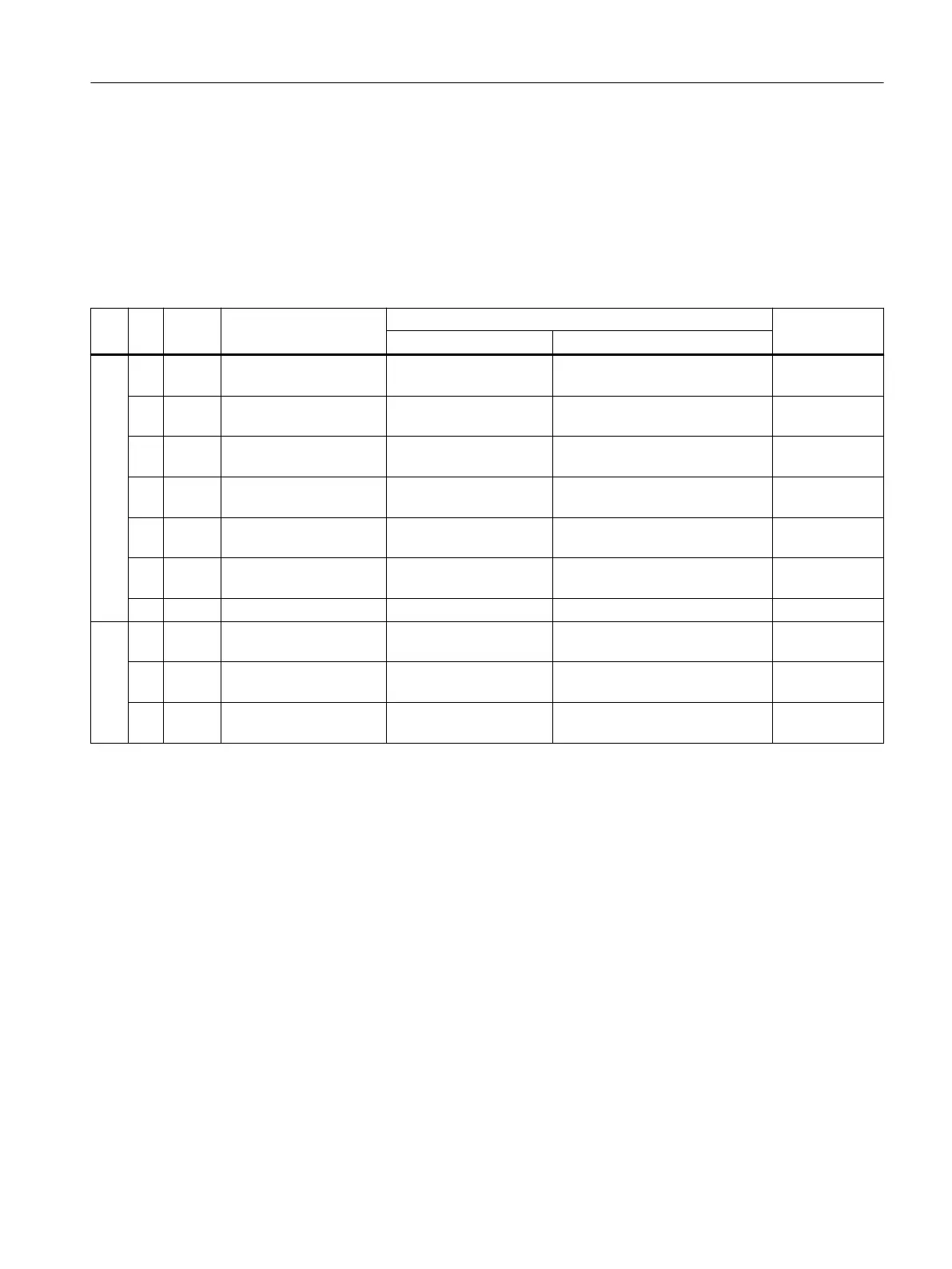

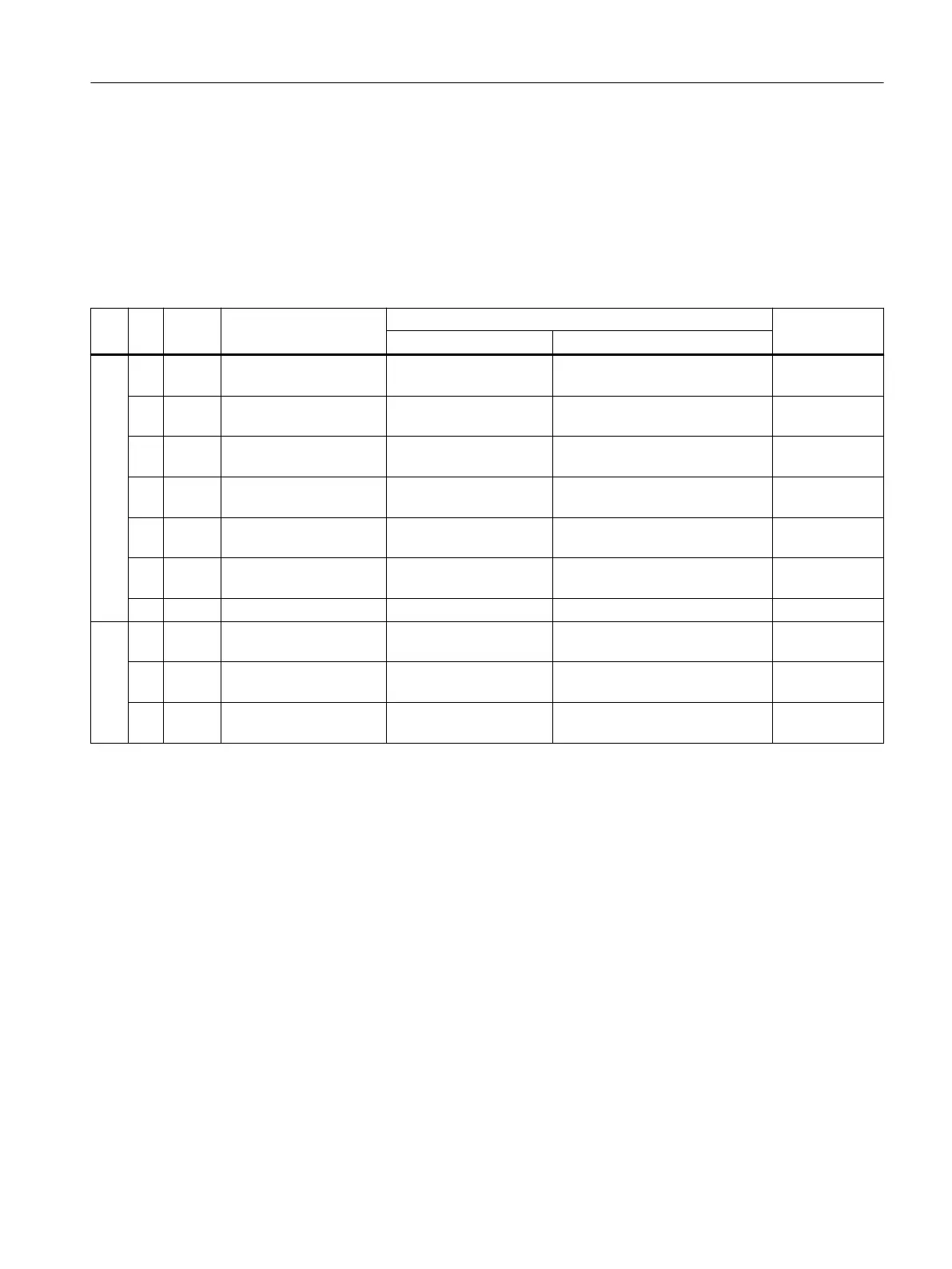

Different status and diagnostics messages can be allocated to individual diagnostics events as

per the following tables. The frame in which an allocation is possible is defined by the group in

the selection column. The following principle is used: in case of three-stage diagnostics events

of the MAINTENANCE group, the effect of the higher lever events can be downgraded, but that

of the lower level events cannot be upgraded.

DIAGNOSTICS_EXTENSION physical block parameter

Byt

e

Bit No. Diagnostics events Effect of the event

1)

Group

Quality status code DIAGNOSTICS bit

0 0 1 Run time error of the ac‐

tuator

Good, Ok DIA_MAINTENANCE_ALARM M

1 2 The device is not in the

"Automatic mode"

Good, check function /

manual mode

DIA_FUNCTION_CHECK F

2 3 Binary 1 is active (only

message)

Good, Ok DIA_MAINTENANCE_DEMAN‐

DED

M, F, P

3 4 Action triggered by bina‐

ry input 1

Good, Ok DIA_FUNCTION_CHECK M, F, P

4 5 Binary 2 is active (only

message)

Good, Ok DIA_MAINTENANCE_DEMAN‐

DED

M, F, P

5 6 Action triggered by bina‐

ry input 2

Good, Ok DIA_FUNCTION_CHECK M, F, P

7 ... 21 Reserved - - -

2 5 22 Limit for alarm A1 ex‐

ceeded

Good, maintenance re‐

quirement

DIA_MAINTENANCE None, hard-co‐

ded

6 23 Limit for alarm A2 ex‐

ceeded

Good, maintenance re‐

quirement

DIA_MAINTENANCE None, hard-co‐

ded

7 24 Error in the device elec‐

tronic unit

Bad, maintenance re‐

quirement

DIA_MAINTENANCE_ALARM None, hard-co‐

ded

Functions/operations using PROFIBUS PA

9.3 Cyclic data transfer

SIPART PS2 with PROFIBUS PA

Operating Instructions, 05/2019, A5E00127926-AC 231

Loading...

Loading...