Byt

e

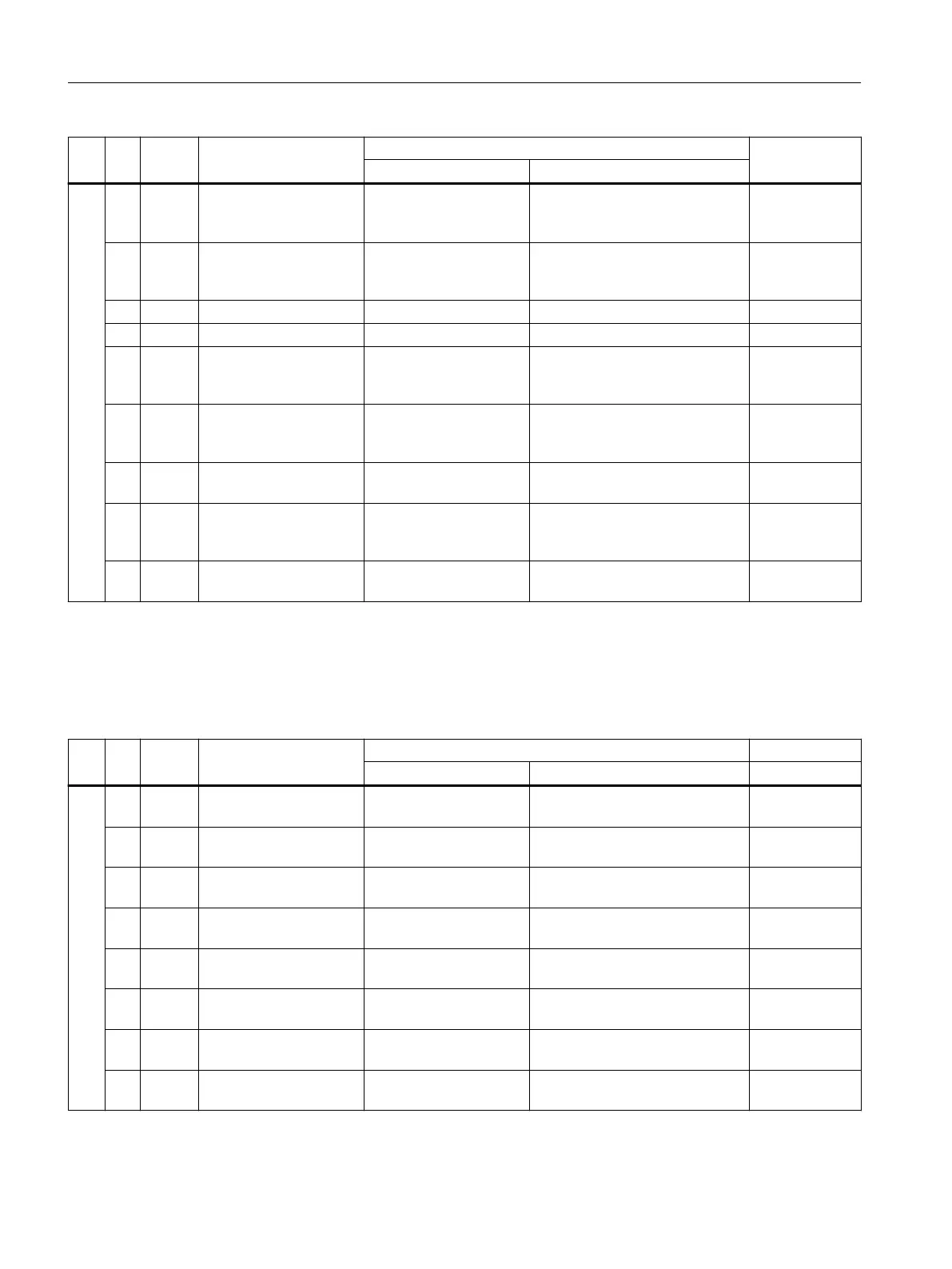

Bit No. Diagnostics events Effect of the event

1)

Group

Quality status code DIAGNOSTICS bit

3 0 25 The device is not yet

ready for operation (not

initialized)

Bad, maintenance re‐

quirement

DIA_MAINTENANCE_ALARM None, hard-co‐

ded

1 26 The device is not yet

ready for operation (initi‐

alization error)

Bad, maintenance re‐

quirement

DIA_MAINTENANCE_ALARM None, hard-co‐

ded

3 27 Reserved - - -

3 28 Reserved - - -

4 29 Device in the Manual

mode (FB in the Manual

mode)

- DIA_FUNCTION_CHECK None, hard-co‐

ded

5 30 Device in the Simulation

mode (FEEDBACK is si‐

mulated)

Depends on the simula‐

ted status

DIA_FUNCTION_CHECK None, hard-co‐

ded

6 31 Device in the TRACE

mode

- DIA_FUNCTION_CHECK None, hard-co‐

ded

7 32 Diagnostics simulation

(diagnostics events are

simulated)

Depends on the simula‐

ted diagnostics event

Depends on the simulated diag‐

nostics event

-

33 ...

48

Reserved - - -

1)

Effects of the event can be set using the DIAG_EVENT_SWITCH or DIAG_EVENT_SWITCH_2 parameters (default

settings in this case)

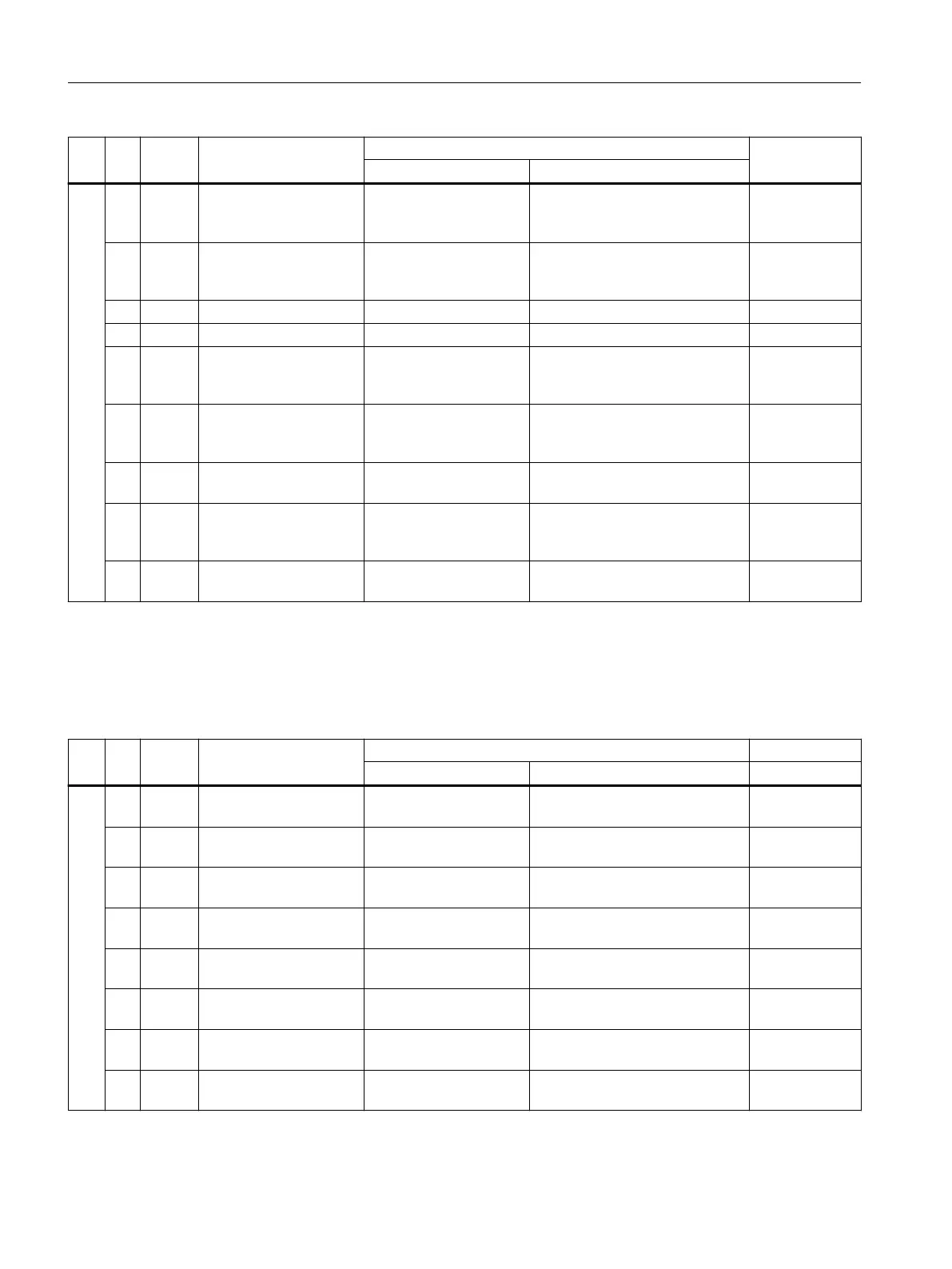

DIAGNOSTICS_EXTENSION_2 physical block parameter

Byt

e

Bit No. Diagnostics events Effect of the event

1)

Quality status code DIAGNOSTICS bit Group

0 0 49 General control valve

fault (limit 1)

Good, maintenance re‐

quirement

DIA_MAINTENANCE M1

1 50 General control valve

fault (limit 2)

Good, maintenance re‐

quirement

DIA_MAINTENANCE_DEMAN‐

DED

M12

2 51 General control valve

fault (limit 3)

Uncertain, maintenance

demand

DIA_MAINTENANCE_ALARM M

3 52 Pneumatic leakage (lim‐

it 1)

Good, maintenance re‐

quirement

DIA_MAINTENANCE M1

4 53 Pneumatic leakage (lim‐

it 2)

Good, maintenance de‐

mand

DIA_MAINTENANCE_DEMAN‐

DED

M12

5 54 Pneumatic leakage (lim‐

it 3)

Uncertain, maintenance

demand

DIA_MAINTENANCE_ALARM M

6 55 Static friction (limit 1) Good, maintenance re‐

quirement

DIA_MAINTENANCE M1

7 56 Static friction (limit 2) Good, maintenance de‐

mand

DIA_MAINTENANCE_DEMAN‐

DED

M12

Functions/operations using PROFIBUS PA

9.3 Cyclic data transfer

SIPART PS2 with PROFIBUS PA

232 Operating Instructions, 05/2019, A5E00127926-AC

Loading...

Loading...