Section 06 REAR SUSPENSION

Sub-Section 02 (SC-10 SUSPENSIONS (ALL VERSIONS))

06-02-16

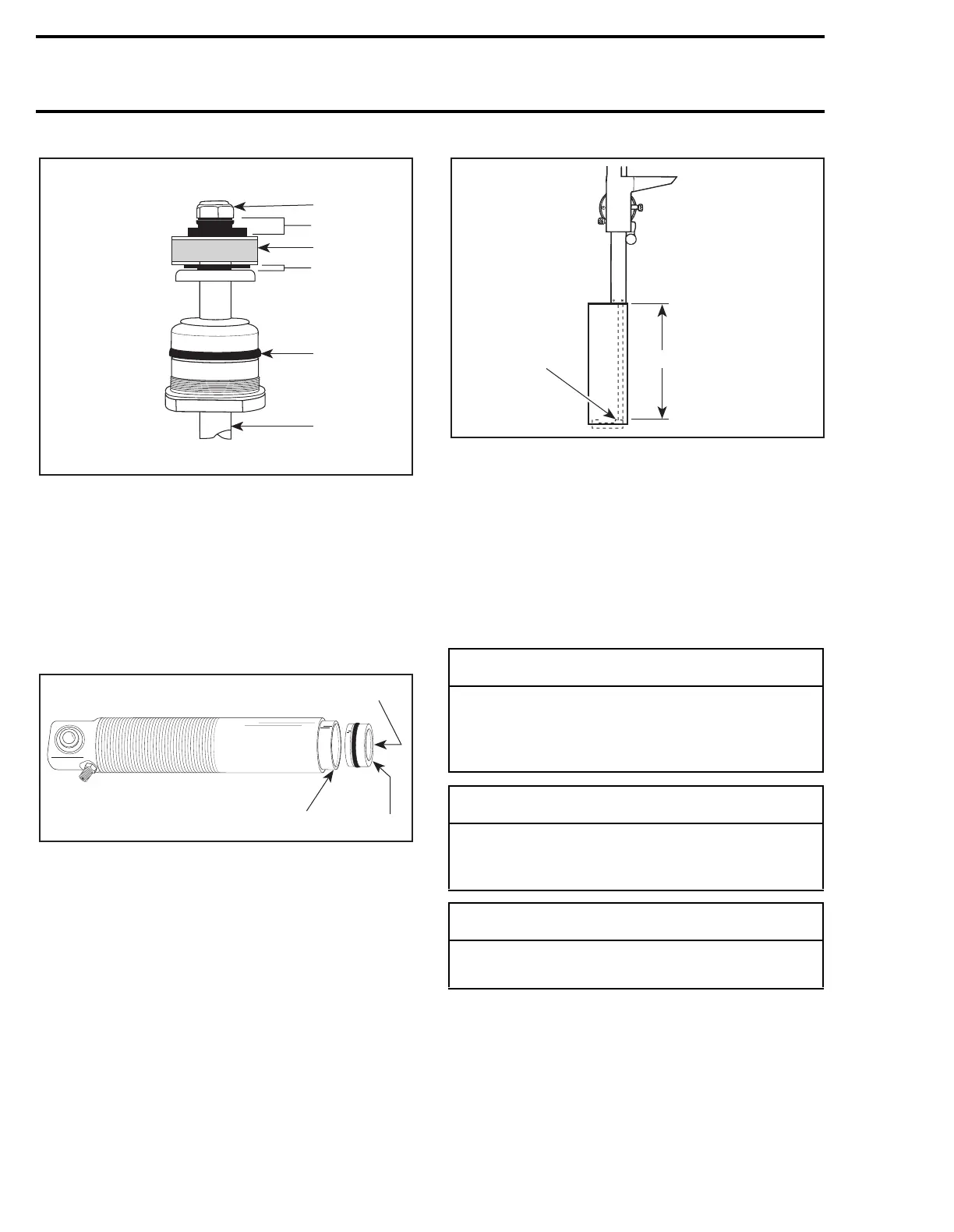

1. Damper nut torqued to 11-13 N•m (96-108 lbf•in)

2. Rebound shim pack

3. Piston

4. Compression shim pack

5. O-ring visual inspection seal carrier assembly

6. Damper rod

Reinstall floating piston into damper body. Use

molybdenum disulfide grease (example: molykote

GN paste (P/N 413 7037 00) to ease O-ring past

damper body threads with floating piston guide

(P/N 529 0266 00).

1. Push (slowly) by hand

2. Hollow side of floating piston must face rod side

NOTE:

Lubricate inside of piston guide with

molykote GN paste (P/N 413 7037 00).

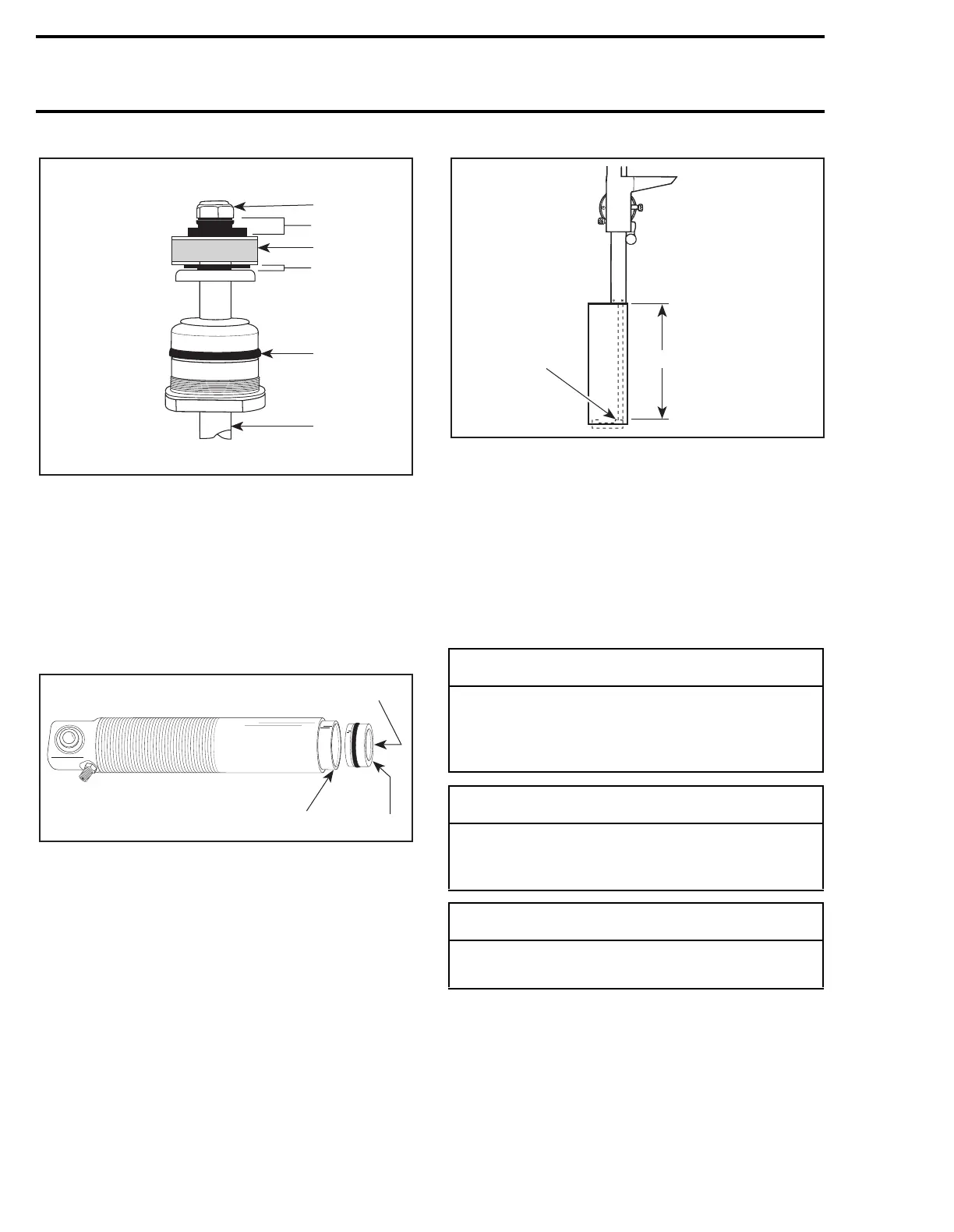

1. Top of the piston

A. Required distance

Install floating piston to depth of 151 mm (5.94 in)

for front damper, 190 mm (7.48 in) for rear damp-

er and 141 mm (5.55 in) for center damper. Mea-

sure from the top edge of the damper body.

NOTE:

If the floating piston is installed too

far into the damper body, light air pressure

through Schrader valve (with core removed) will

move piston outward.

Replace shock oil with Bombardier HPG shock oil,

(P/N 413 7094 00), to approximately 10 mm (.393

in), from the base of seal carrier threads.

A06F2DA

1

2

3

4

5

6

A06F14B

1

529 0266 00

2

◆

WARNING

Whenever using compressed air exercise

extreme caution, cover damper opening

with shop cloth to reduce chance of possible

injury.

-

CAUTION

Moisture laden compressed air will contami-

nate the gas chamber and rust floating pis-

ton.

◆

WARNING

Always wear protective eye wear whenever

using compressed air.

A27F07A

1

A

'

Loading...

Loading...